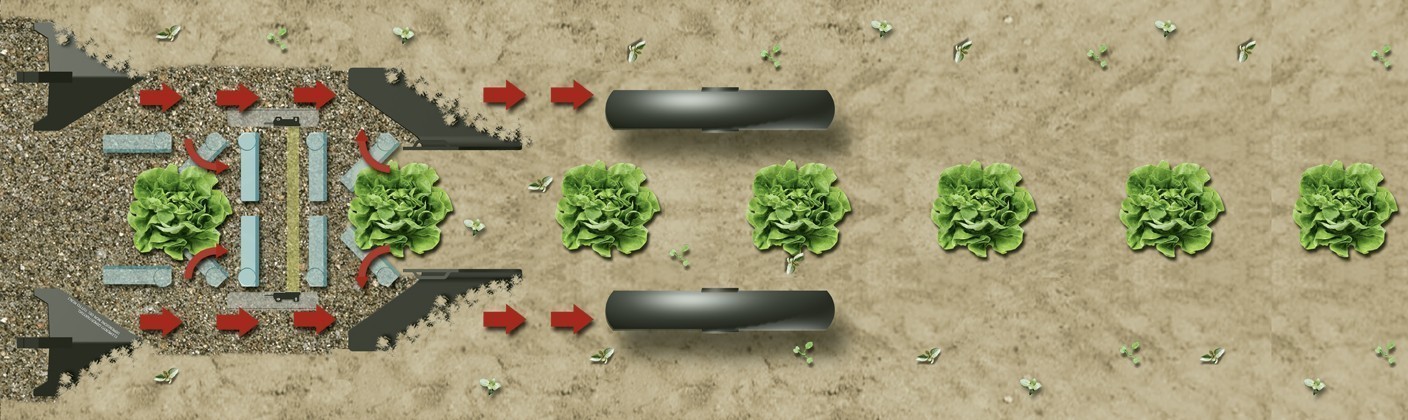

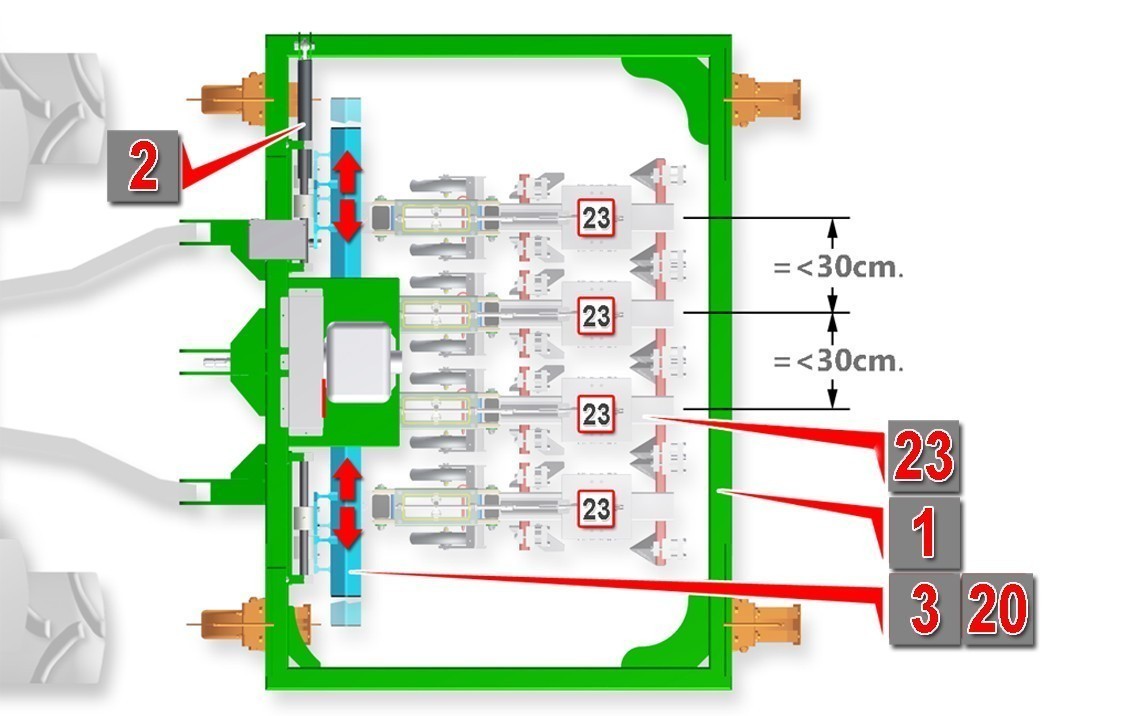

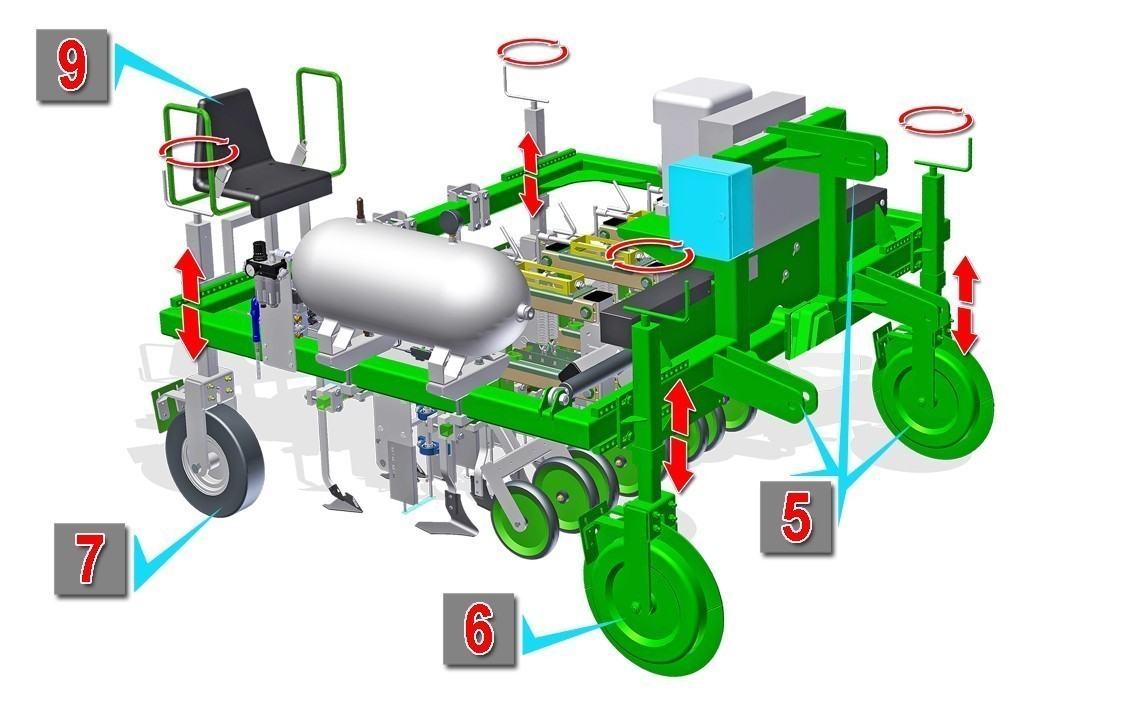

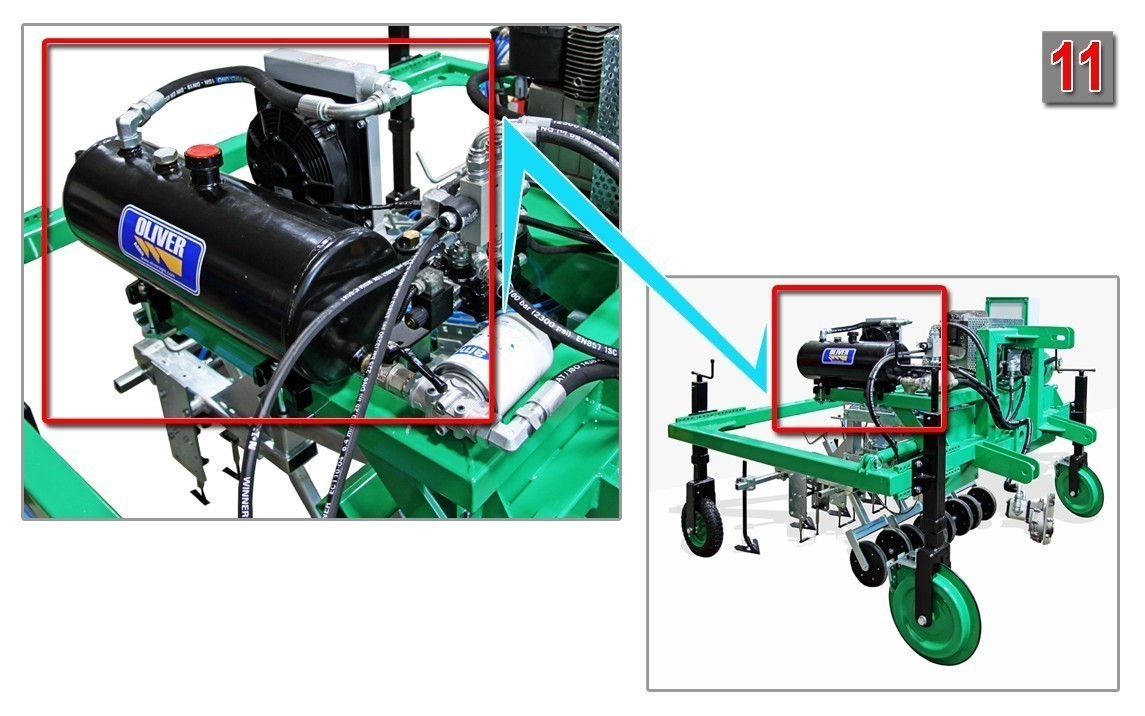

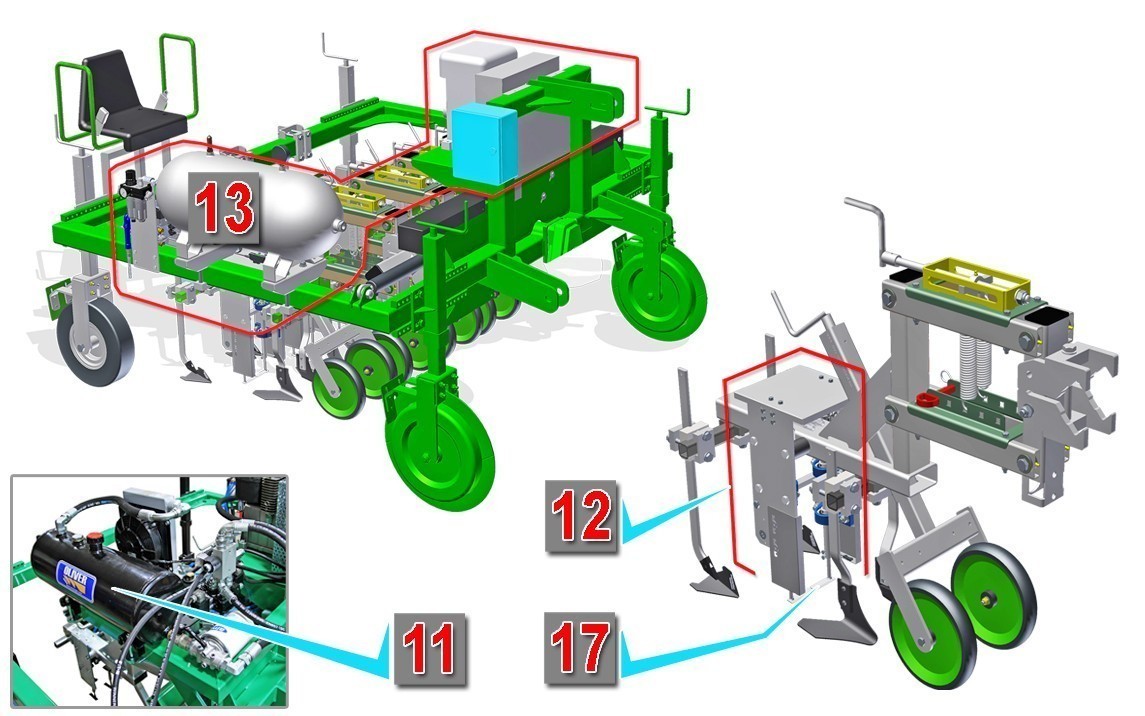

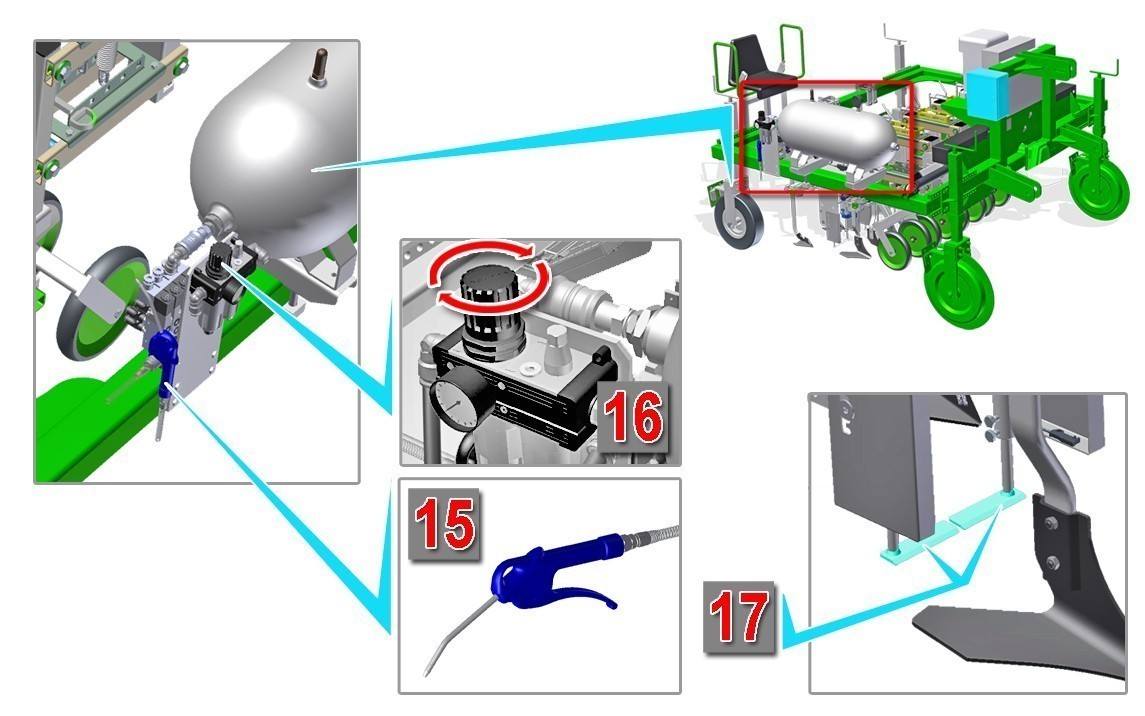

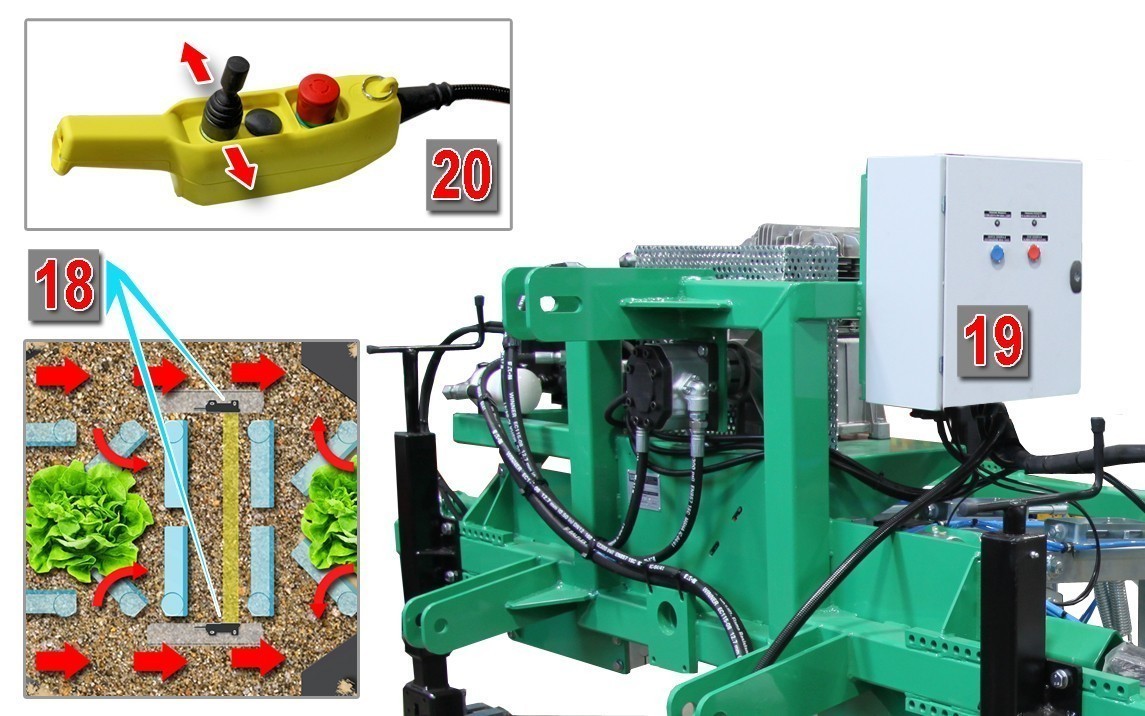

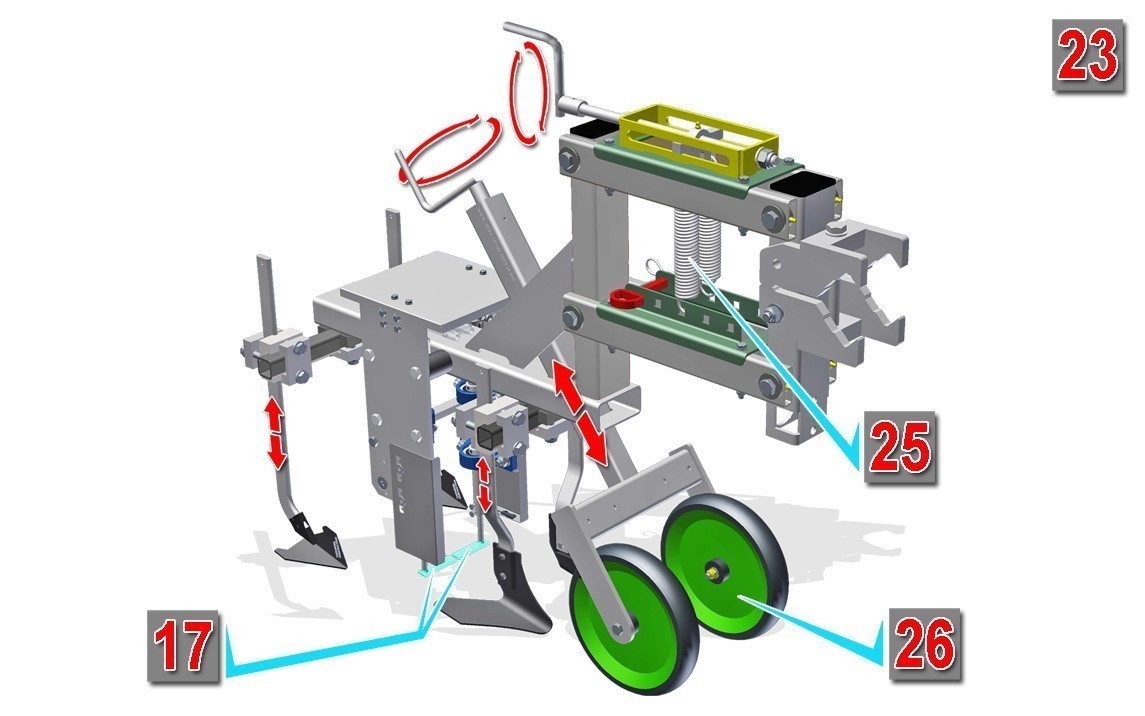

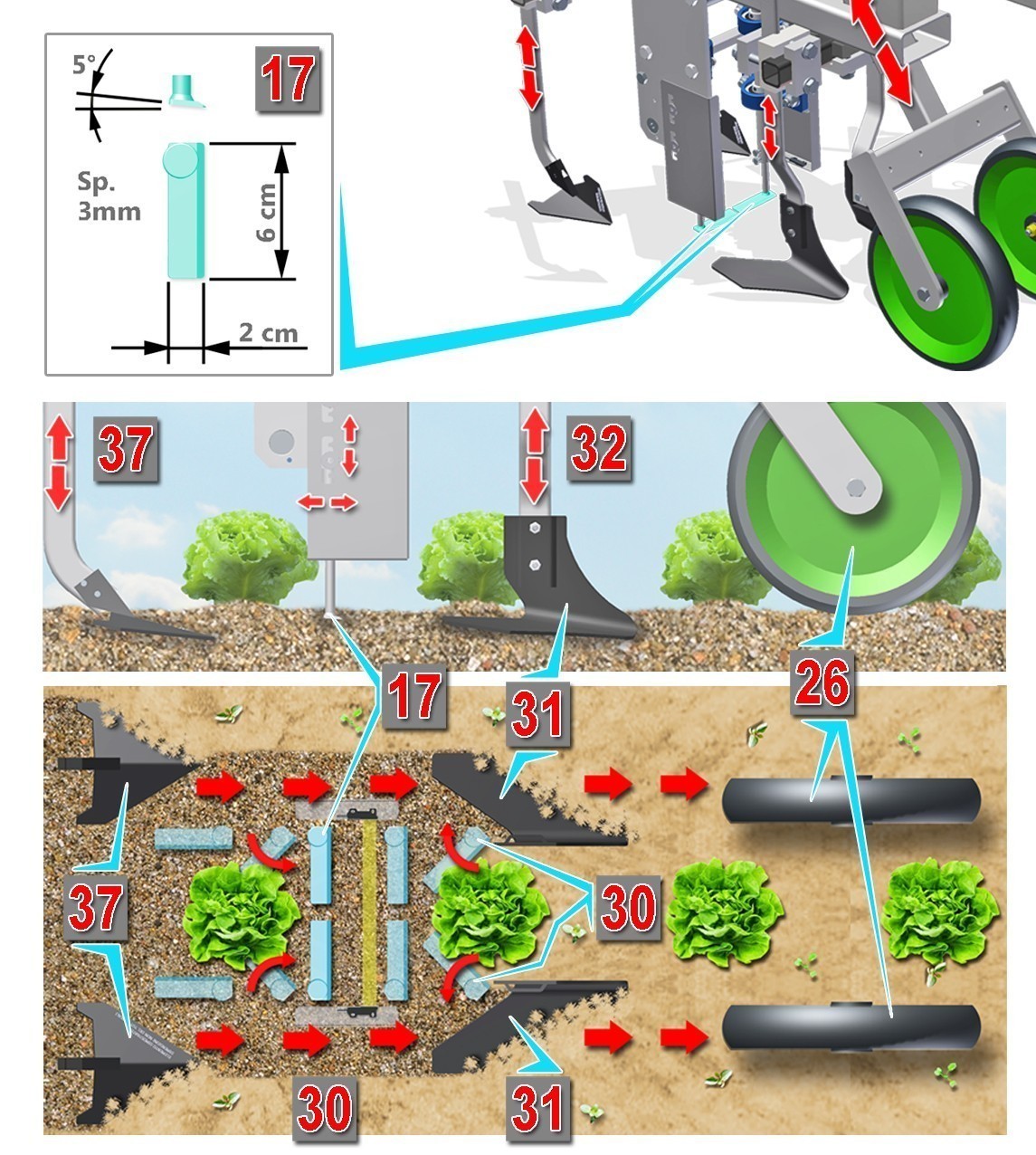

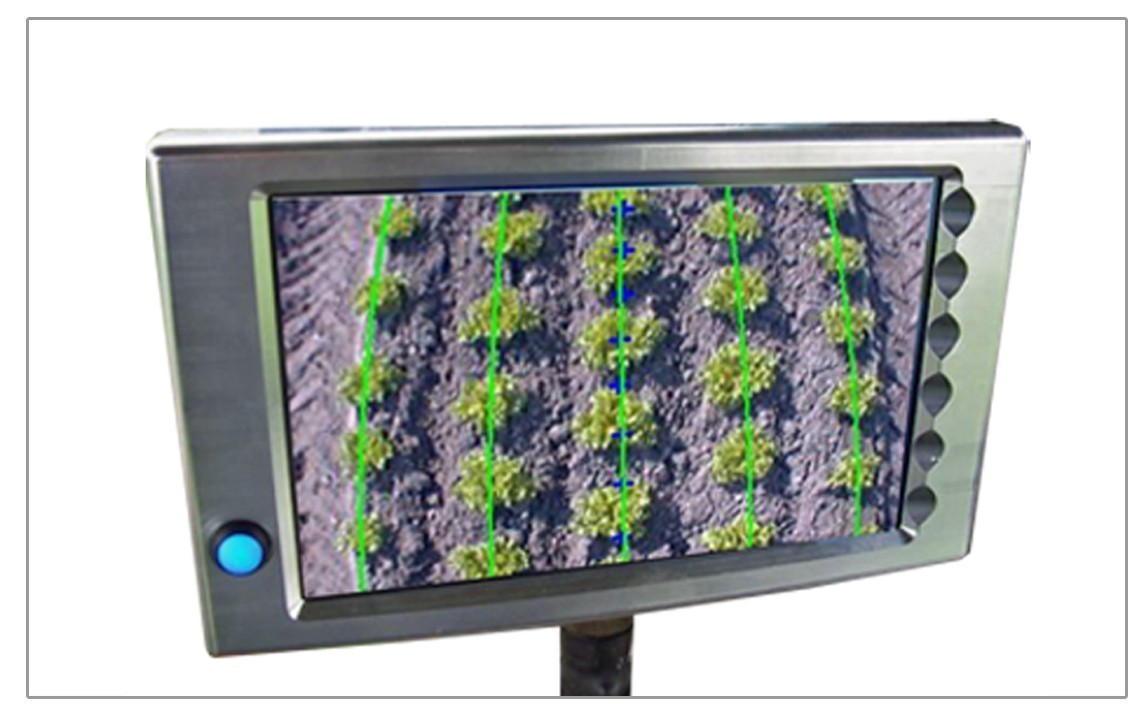

With our Optyma hoeing machine, you can cultivate the soil between the rows and the plants with his new patented optical fiber sensors. You can easily work on many different crops such as salad, chicory, broccoli, cauliflower, hemp and in general in every transplanted or seeded crop on bed or on flat soil..

• Patented;

• highly precise and reliable;

• revolutionary, unique and inimitable;

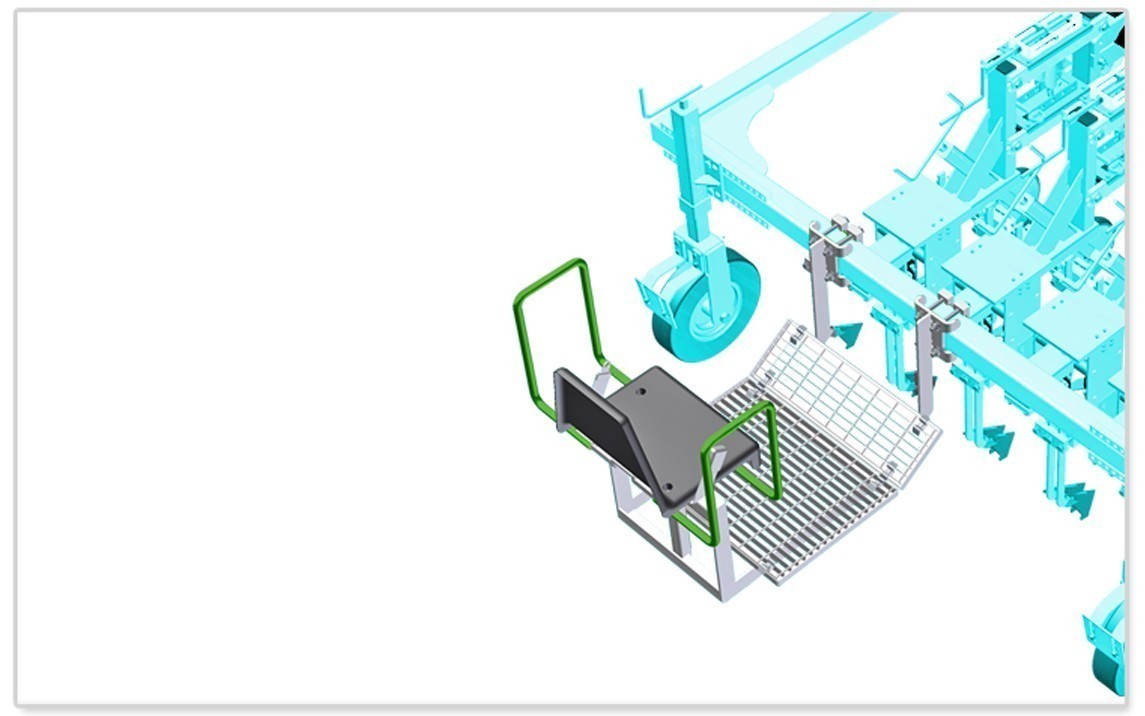

• flexible with several configurations;

• easy to use;

• Average working speed from 1.2 to 1.5 km/h or 2 to 4 km/h.