ROTODISK weeding machine with fixed frame; modular with multiple inter-row

parallelograms with support wheel to work at the base of the ridge.

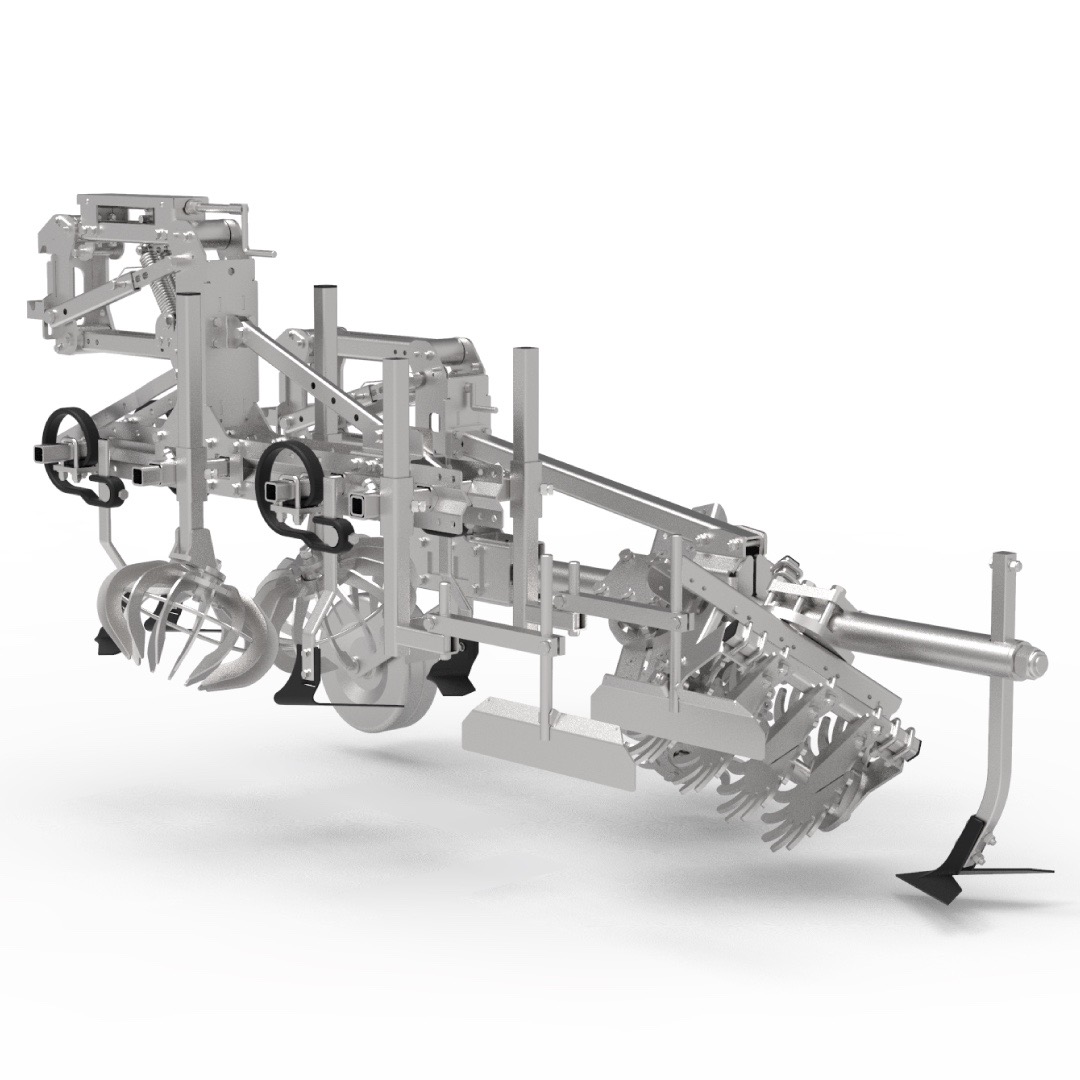

The ROTODISK is a high-performance combined weeding machine, designed for differentiated intervention between the top and sides of the ridge, ensuring complete and precise weed control in a single pass.

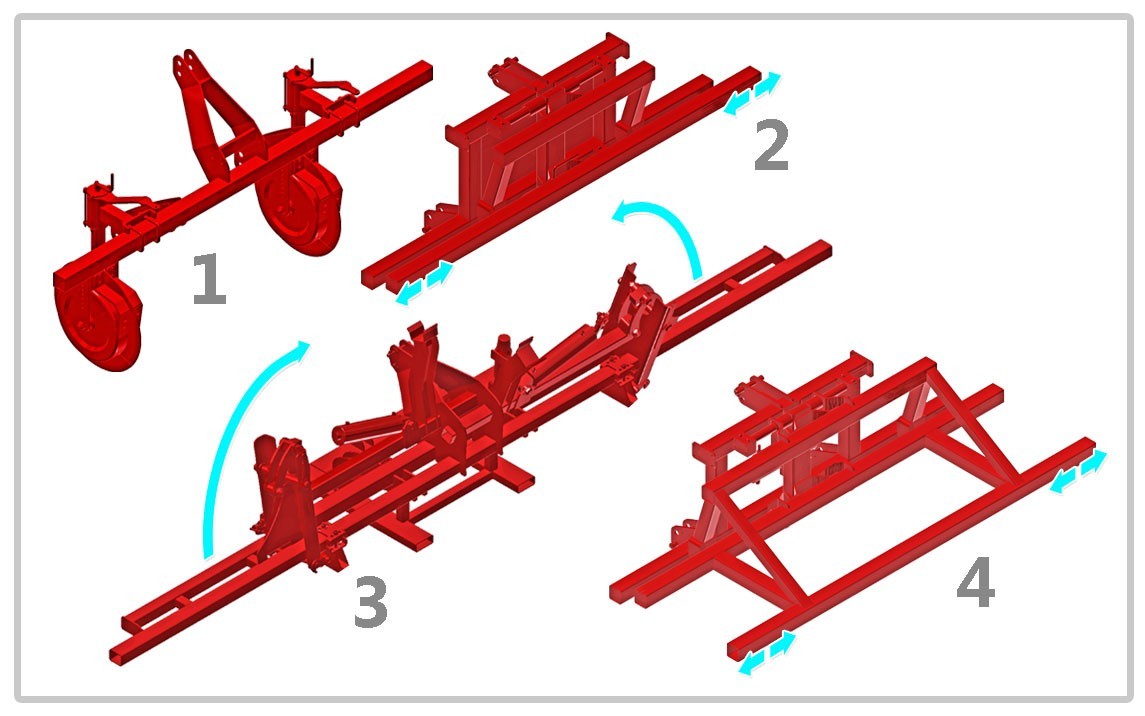

The configuration integrates two distinct weeding systems mounted on the same supporting frame:

Top of the ridge (ridge crest):

This section is worked by ROTOSARK, ROTOVERT, or TILT elements, available in single or multiple-row configurations.

These units are mounted on an independent side-shifting frame with hydraulic adjustment, specifically designed to follow the crop rows with extreme precision—even in the presence of non-linear planting or transplanting.

The shifting movement can be controlled either hydraulically via joystick by the operator, or automatically via camera systems or visual guidance technologies.

Ridge sides (inter-ridge area):

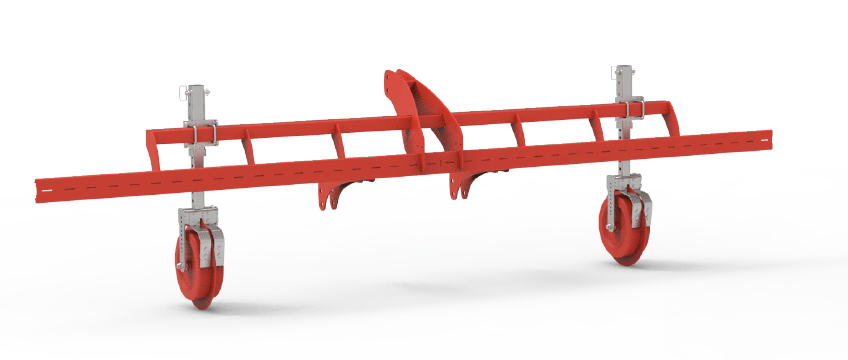

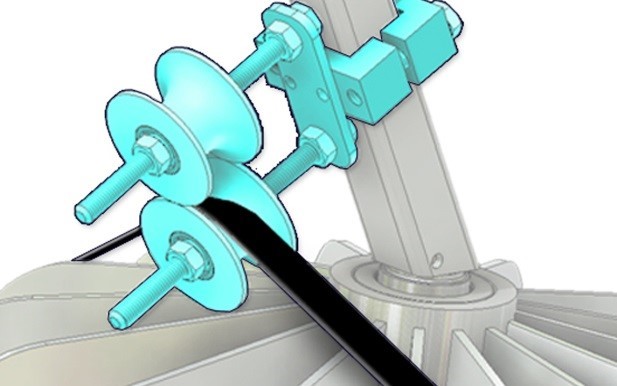

The sides are worked by ROTOdisk elements mounted on a fixed bar attached to the main frame of the machine.

These angled, counter-rotating discs break up soil crusts along the ridge flanks and suppress weed competition without damaging the cultivated plants.

Operational Benefits:

-

Suitable for ridge crops such as potatoes, tobacco, strawberries, and ridge-grown vegetables;

-

Maximum adaptability to curves and irregular row alignments thanks to the side-shifting frame;

-

Combined action for intra-row (ridge top) and inter-ridge (ridge sides) weeding in a single pass;

-

Compatible with visual guidance or GPS steering systems;

-

Modular configurations available with 2, 4, 5 or more rows, depending on ridge width and spacing;

-

Precise, fast, and scalable operation across various soil types.

| TYPE OF SOIL | Sandy/medium texture and stony (with small stones: about 2–3 cm in diameter) |

| ROW SPACING | > 75 cm |

| INTER-PLANT DISTANCE | – |

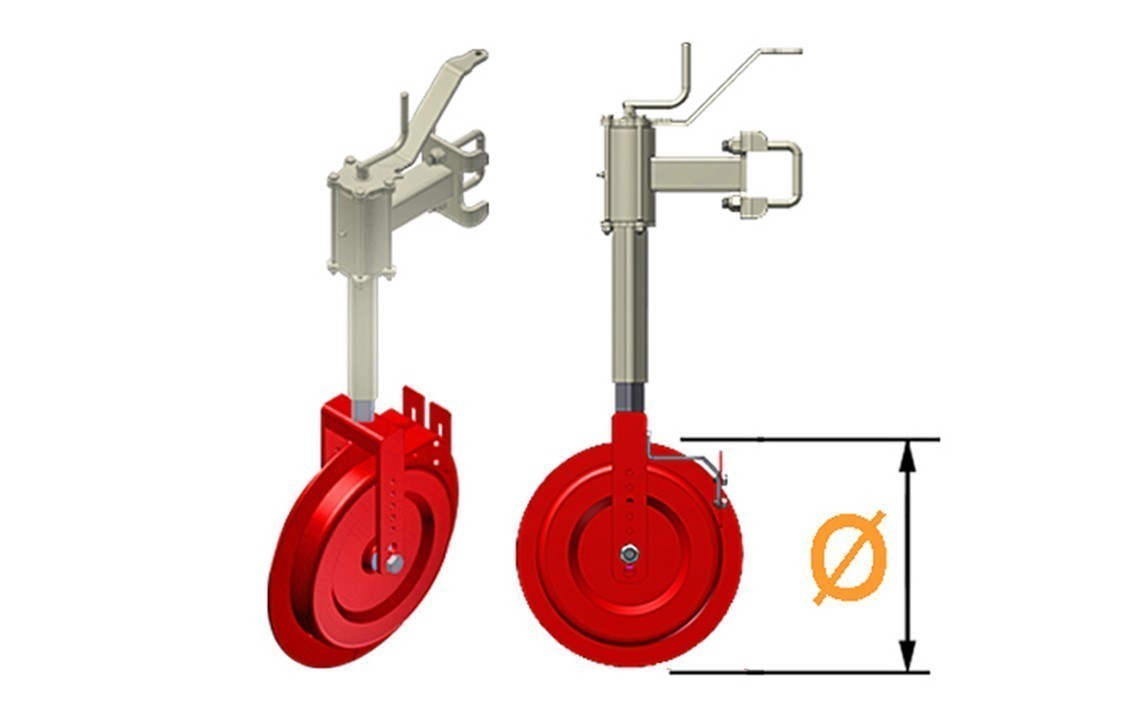

| ROTOR DIMENSIONS | A unique ROTODISK model with adjustable angle, shift, and rotation |

| WORKING SPEED | 6 – 8 Km/hr |

| REQUIRED PREPARATION OF THE LAND | Good |

| ROW N. | Depending on the bed former being used |

| SYSTEM TYPE | Mechanic |

| USE | Intuitive and modular |