Weeding

WEEDING AS A GOOD AGRICULTURAL PRACTICE: FROM THE PAST TO THE FUTURE FOR A MORE SUSTAINABLE AGRICULTURE

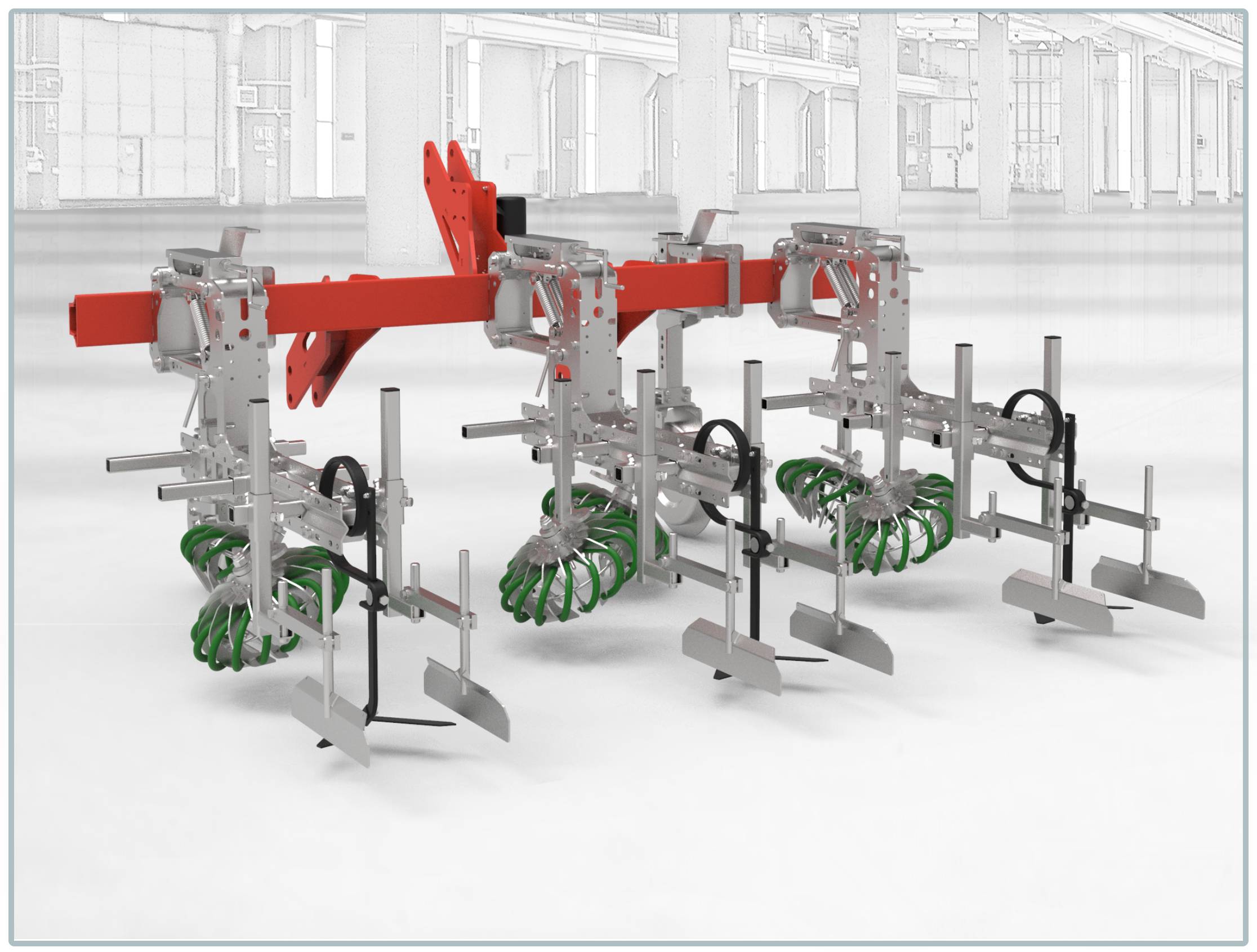

Harrowing is once again proving to be an effective solution against weeds, supported by the improved crop yield. In this page, we will guide you into the world of precision interrow harrows, explaining why they are crucial for modern agriculture and how they can enhance your farming operations.

Weeds can compete with cultivated plants for nutrients, water, and sunlight, thereby reducing the quality and quantity of the harvest. The use of traditional chemical herbicides can pose risks to crops, the environment, human health, and biodiversity.

Due to recent regulations aimed at reducing pollution caused by herbicides in agriculture, Oliver Agro has patented a series of innovative solutions as alternatives to chemical weed control. Interrow and interplant harrows, which have been widely appreciated in the organic sector, are gaining increasing interest in conventional farming as well, including for those seeking residue-free crops.

WHAT SOLUTIONS DOES OLIVER AGRO OFFER FOR WEED CONTROL?

The primary and most important objective of harrowing is similar to uprooting, which is the destruction of weeds. Weeds can compete with plants by depriving them of water and nutrients, thus compromising crop growth.

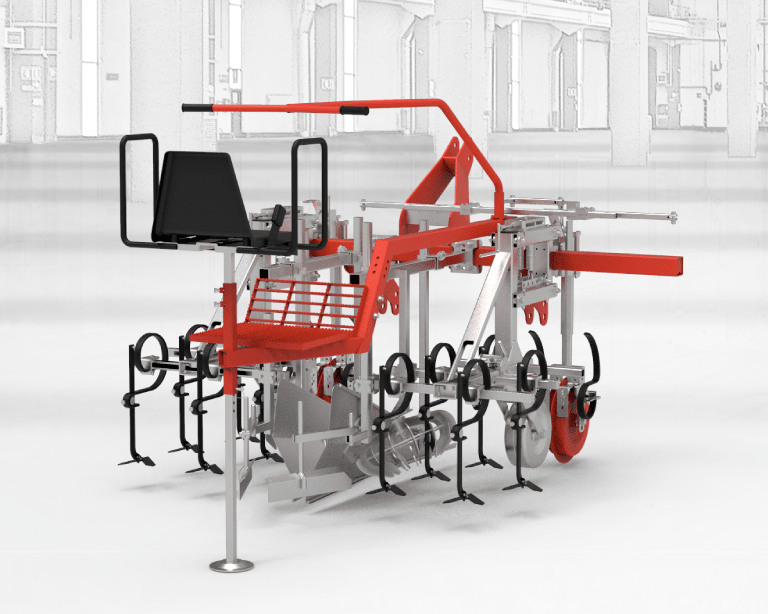

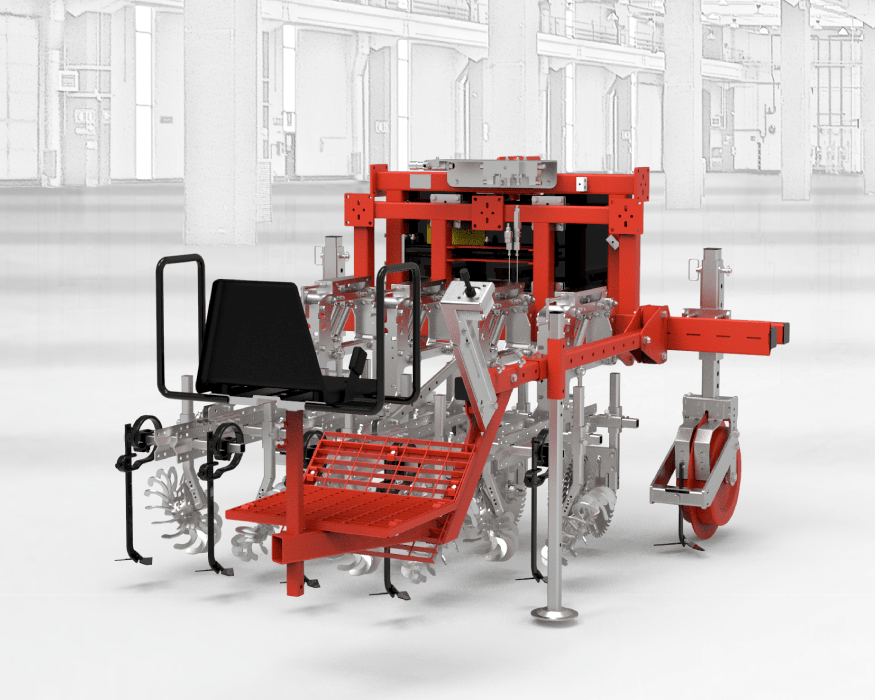

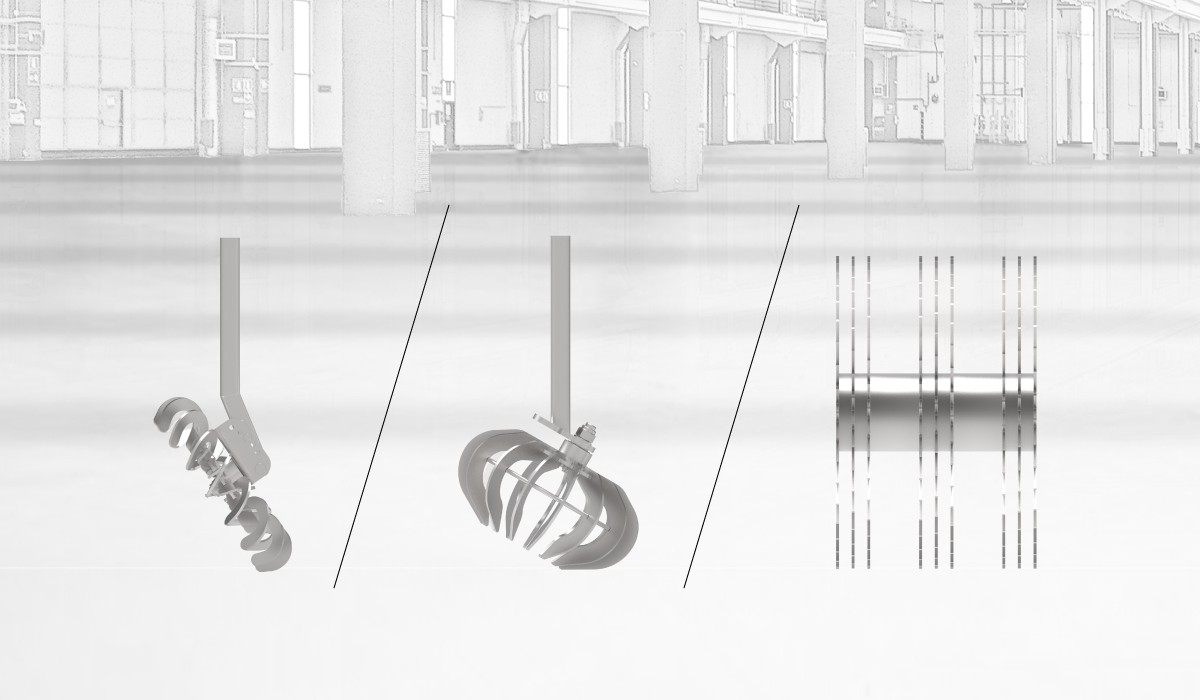

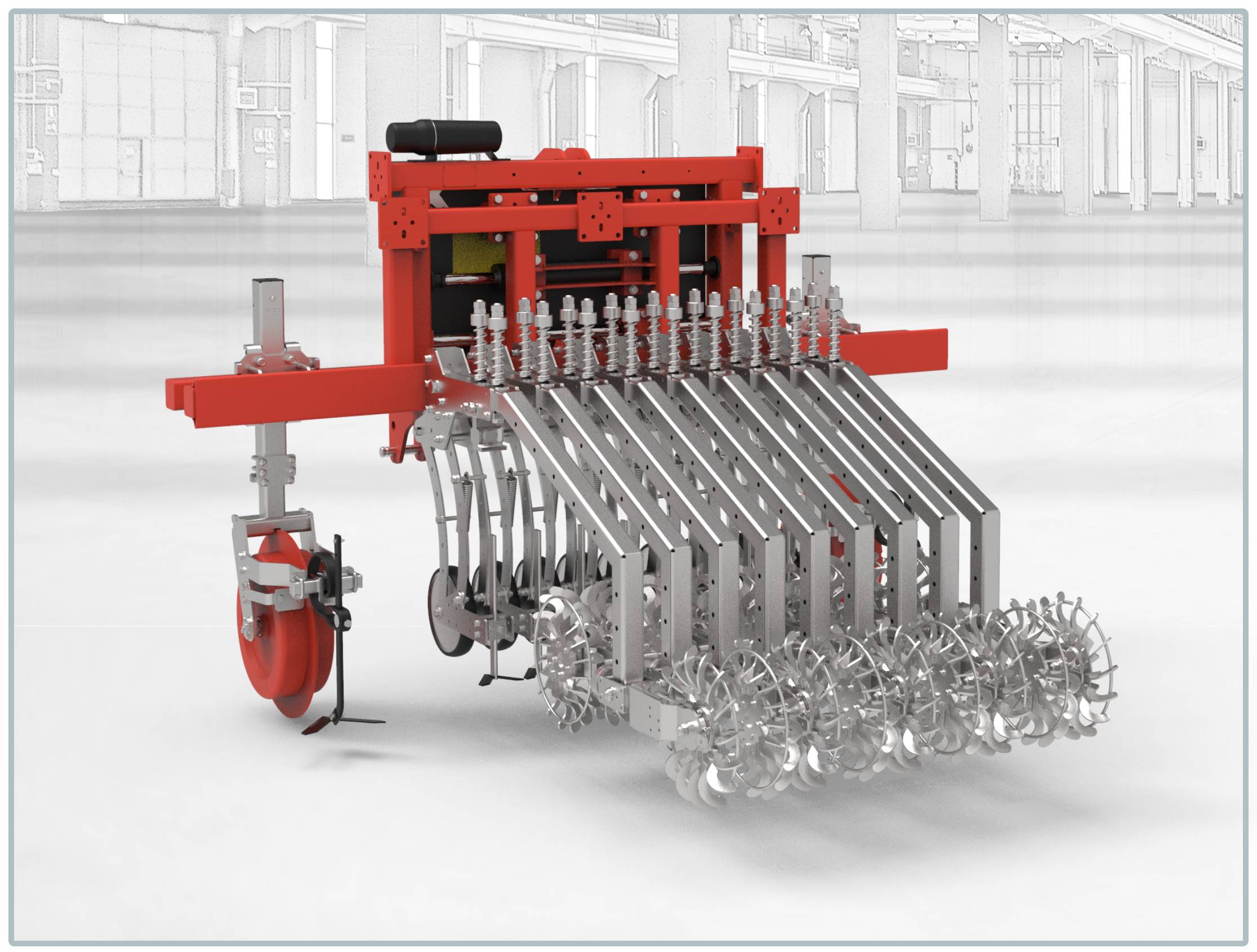

With over 40 years of experience in manufacturing agricultural machinery, specializing in both conventional and organic weeding, Oliver Agro focuses on producing equipment for mechanical weed removal, which is fundamental in organic production. These devices utilize a combination of patented, world-unique harrowing elements such as our Rotosark and Rotovert rotors, Colibrì discs, Rotoclean stars, and Rotodisc kits (including the latest addition, the ROTOFILM rotors) to remove weeds around cultivated plants.

HOW TO CHOOSE THE RIGHT WEEDING OR HOEING MACHINE

The choice of the appropriate harrow depends on specific needs, whether it is for organic or conventional or residue-free cultivation, the type of crops being grown, soil characteristics, land preparation, equipment in use, and other factors. We can assist you in making the best choice for your requirements.

- Rotosark, Rotovert, and Rotofilm: The first patented steel rotor harrow machines specifically designed for mechanical weed control. Applications such as opposing inclined steel rotors (Rotoblizz and Rotovert, Oliver Agro’s international patents) or packs of toothed discs (Colibrì) allow harrowing up to 1/2 cm from the plants, and complementary accessories contribute to achieving optimal results. This equipment is suitable for crops such as Garlic, Onion, Carrot, Beetroot, Cruciferous vegetables, Artichoke, Chickpea, Rapeseed, Fennel, Lettuce, Corn, Bell Pepper, Tomato, Leek, Radicchio, Celery, Soybean, Tobacco, rootstocks, Vine-stocks, Asparagus, Medicinal herbs, and more.

- Colibrì: A weeder-harrow specifically designed for interrow distances starting from 4.5 cm, suitable for precise cultivation.

- Optyma: Our new hoeing machine, an interplant for leafy vegetables such as lettuce, radicchio, transplanted onions, beetroot, cauliflower, cabbage, and more. The interplant hoeing machine Optyma 2.0 performs weeding in the soil near the plant and between the plants thanks to two knives that scratch the ground to a depth of about 2/3 cm without pouring it on the plant.

From this link, based on your specific crop, you can find the most suitable weeder

https://www.oliveragro.com/crop-type/

LATEST INNOVATIONS FROM OLIVER AGRO IN THE FIELD OF HARROWS AND MECHANICAL WEED CONTROL

The sector of harrows and mechanical weed control continues toevolve, especially in organic agriculture, and Oliver Agro is capable of providing cutting-edge solutions and tailor-made technologies for customers. In recent years, we have developed and integrated harrow models with advanced control systems that allow for even more precise operations and a reduction in labor costs.

Mechanical weed control, precision interrow and interplant hoeing are our proposed solutions. These custom-designed harrows are ideal for those who want to work on multiple rows simultaneously, accomplishing weed removal, soil aeration, and reconsolidation in a single operation. They are designed for both transplanted and directly sown organic crops, and they are also appreciated in conventional farming for reducing the use of chemical herbicides and subsequent cost savings.

CONSULT OUR WIDE RANGE OF INTER ROW INTER PLANT WEEDING MACHINES

Showing all 10 results