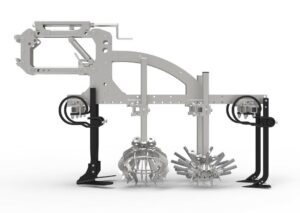

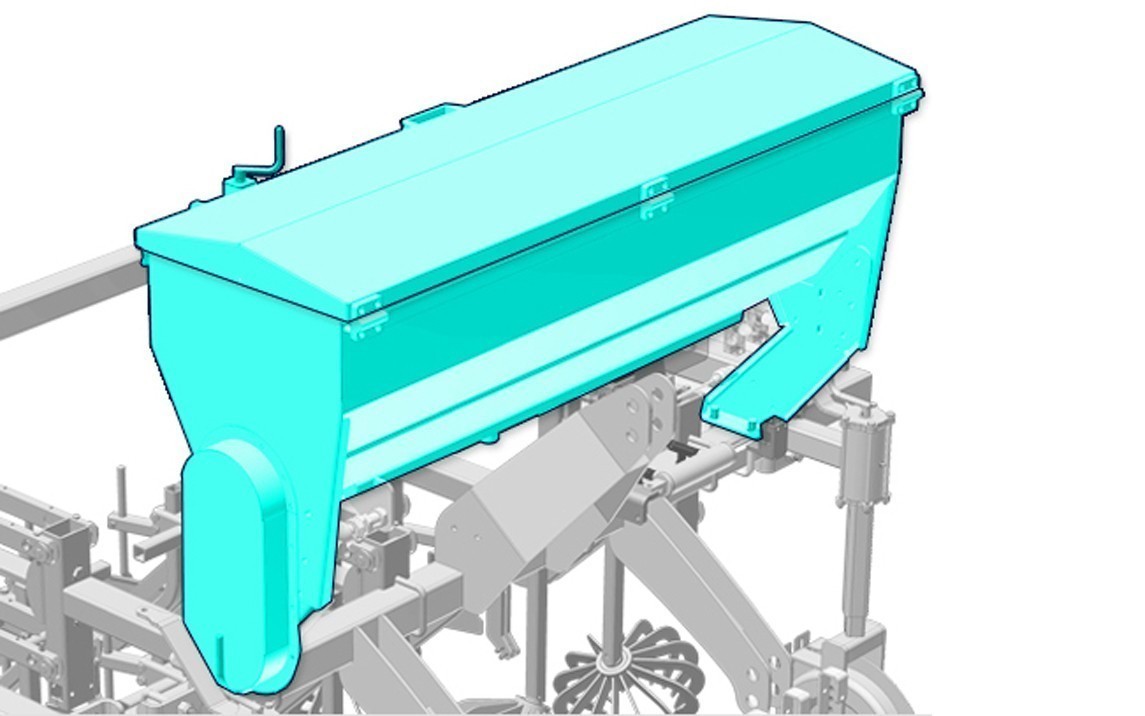

Rotosark with a fixed or shifting frame with Rotostar rotors; it can be configured with one

or more parallelograms that operate on the transplanted row.

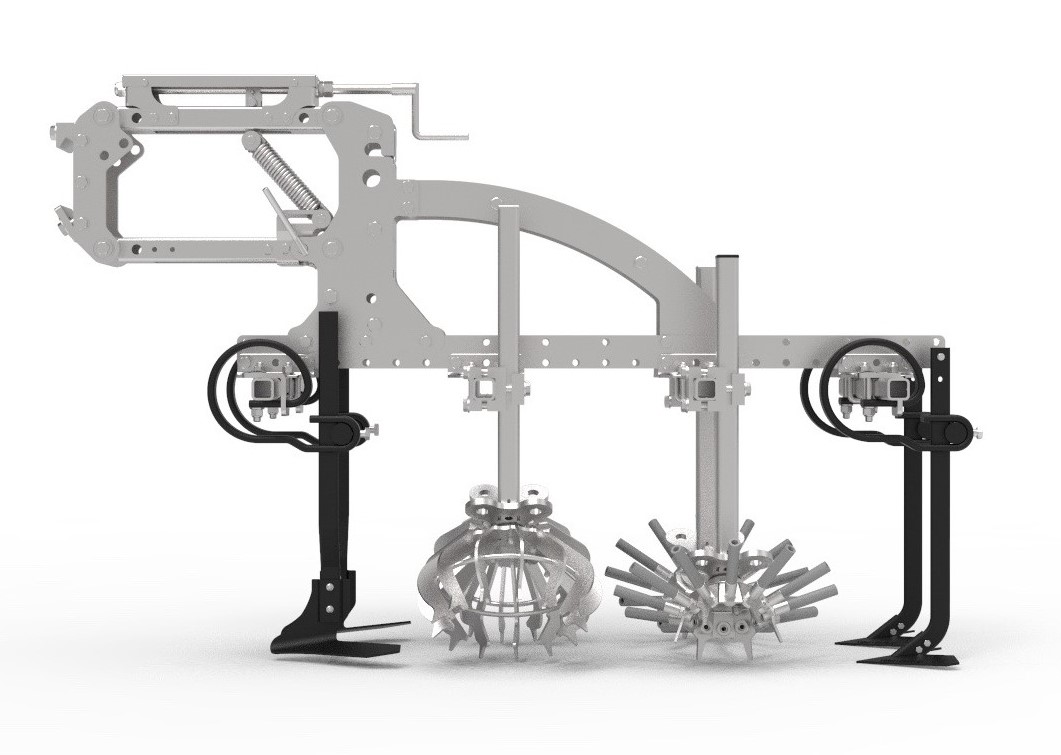

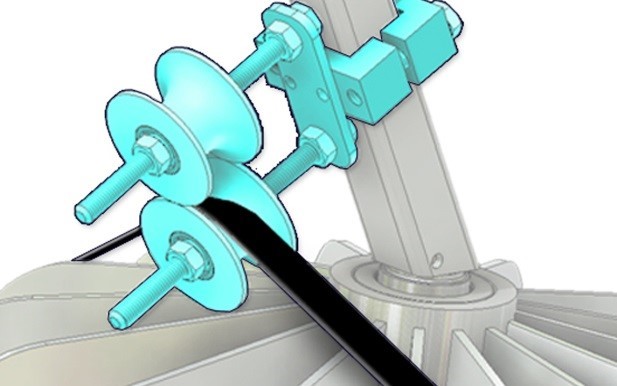

The Rotosark rotor pair, working synergistically with the Rotostar rotor pair, operates directly on the transplant row without damaging the root or leaf system. It uproots weeds more effectively in the intra-plant spacing, particularly in head-forming crops.

Weeding with the synergic pair of Rotostar rotors mounted on the working unit is ideal for transplanted and direct-seeded crops grown on ridges or beds (e.g. lettuce, cabbage, broccoli, cauliflower, radicchio, sugarloaf chicory, fennel, and others), with inter-row spacing starting from 40 cm and above.

| TYPE OF SOIL | Sandy/medium texture and stony (with small stones: about 3–4 cm in diameter) |

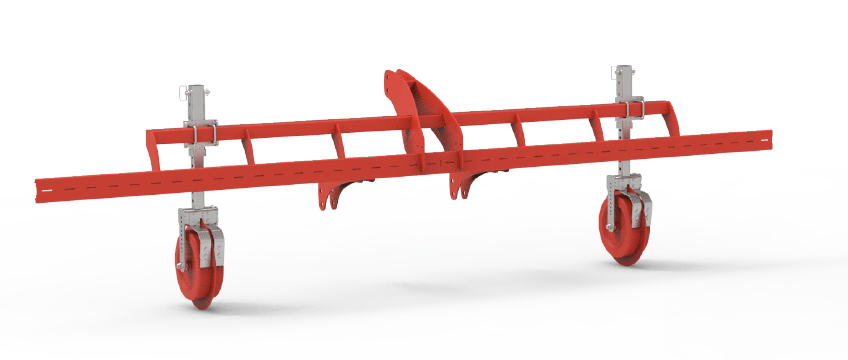

| ROW SPACING | Minimum 40 cm 16’ (inches) – 80 cm 31’ ½ (inches) |

| INTER-PLANT DISTANCE | – |

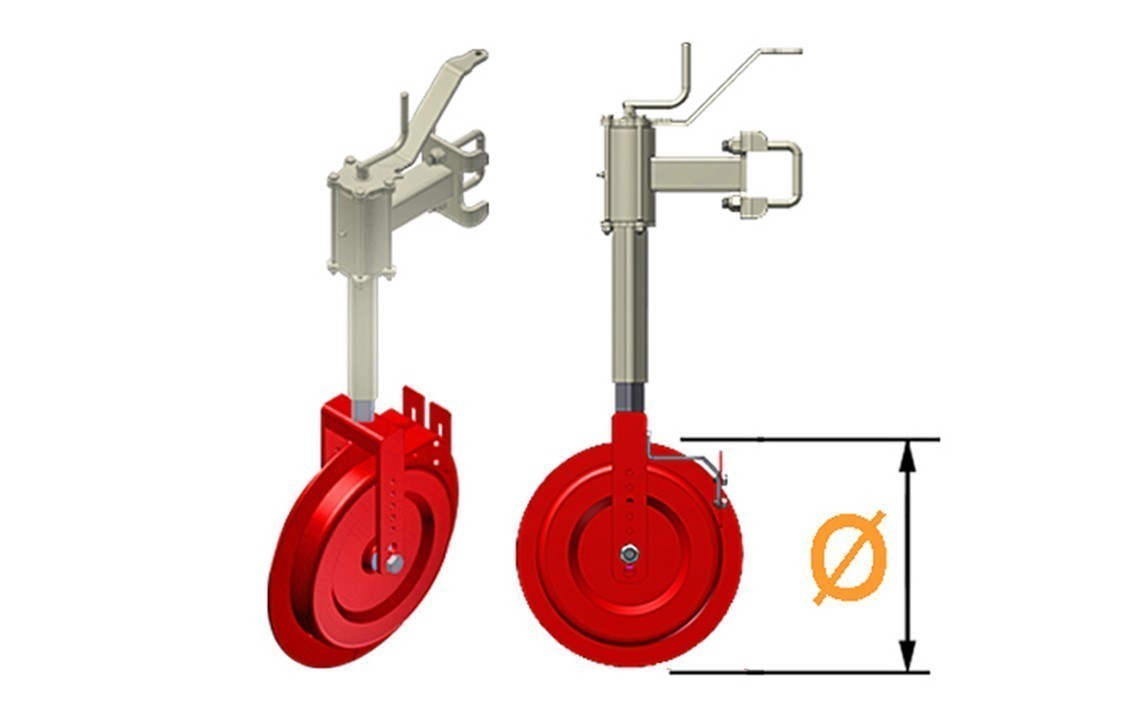

| ROTOR DIMENSIONS | Fixed inclination 28° Rotostar: Ø 36 cm |

| WORKING SPEED | 3 – 9 Km/h |

| REQUIRED PREPARATION OF THE LAND | Good and without crop residues |

| ROW N. | Depending on the transplanter, even on multiple beds |

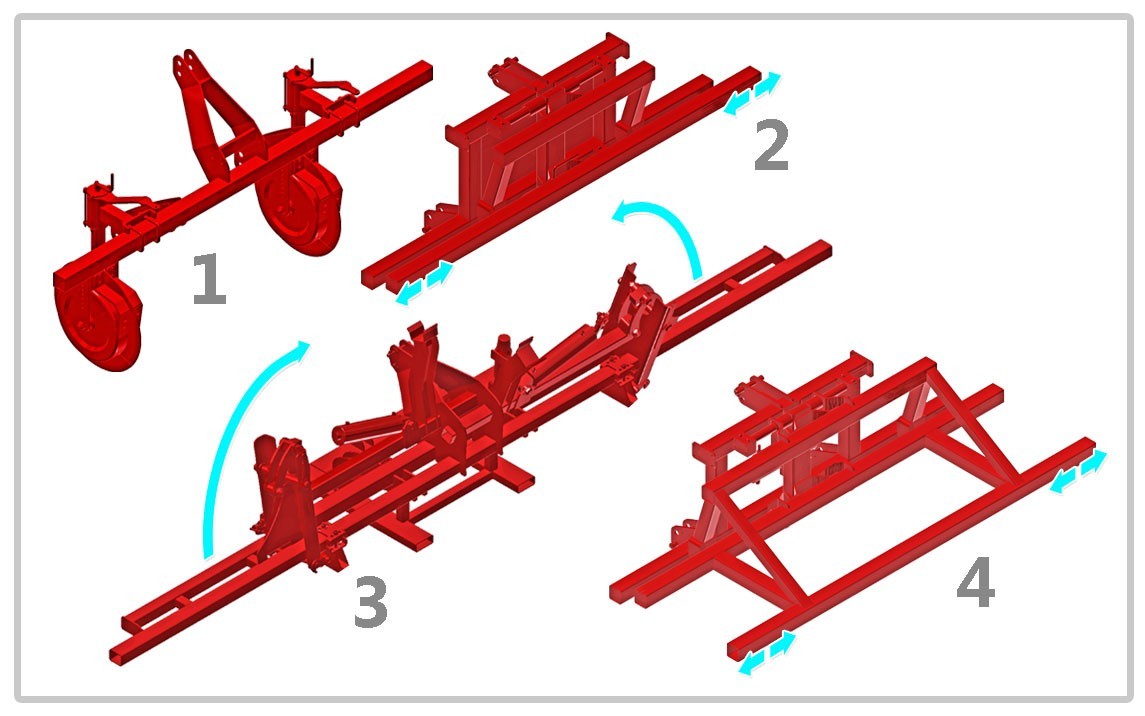

| SYSTEM TYPE | Mechanic |

| USE | Intuitive and modular |