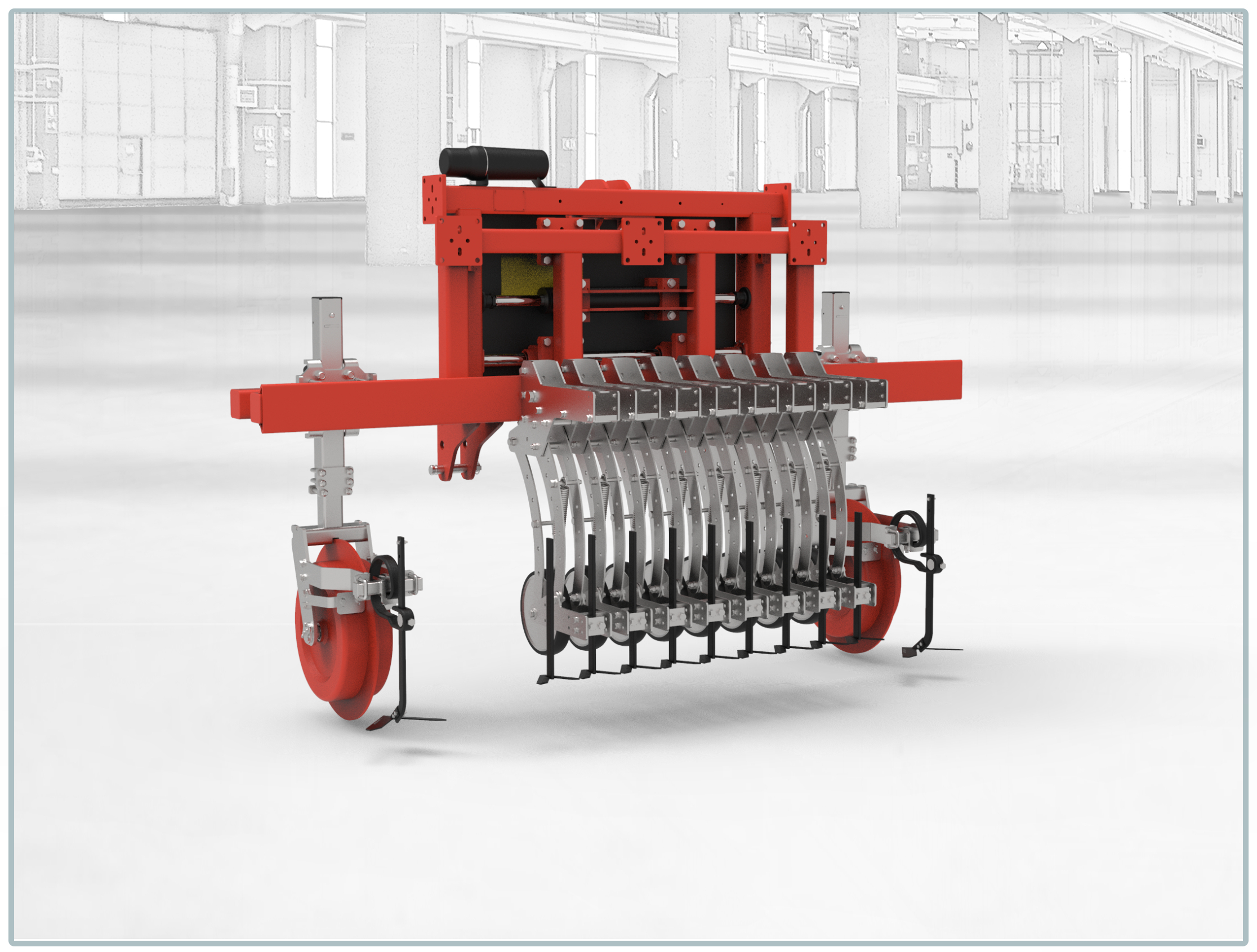

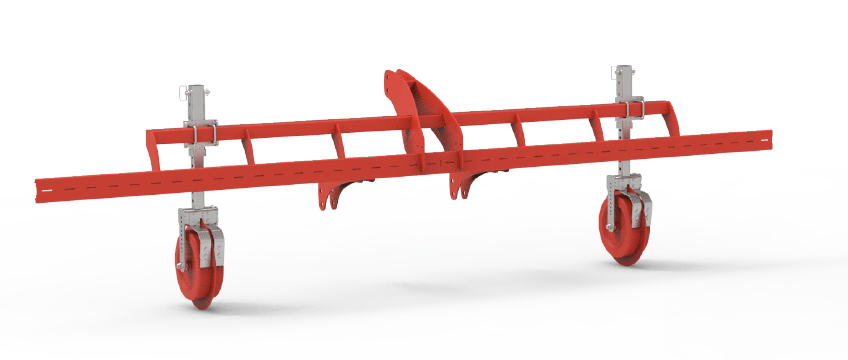

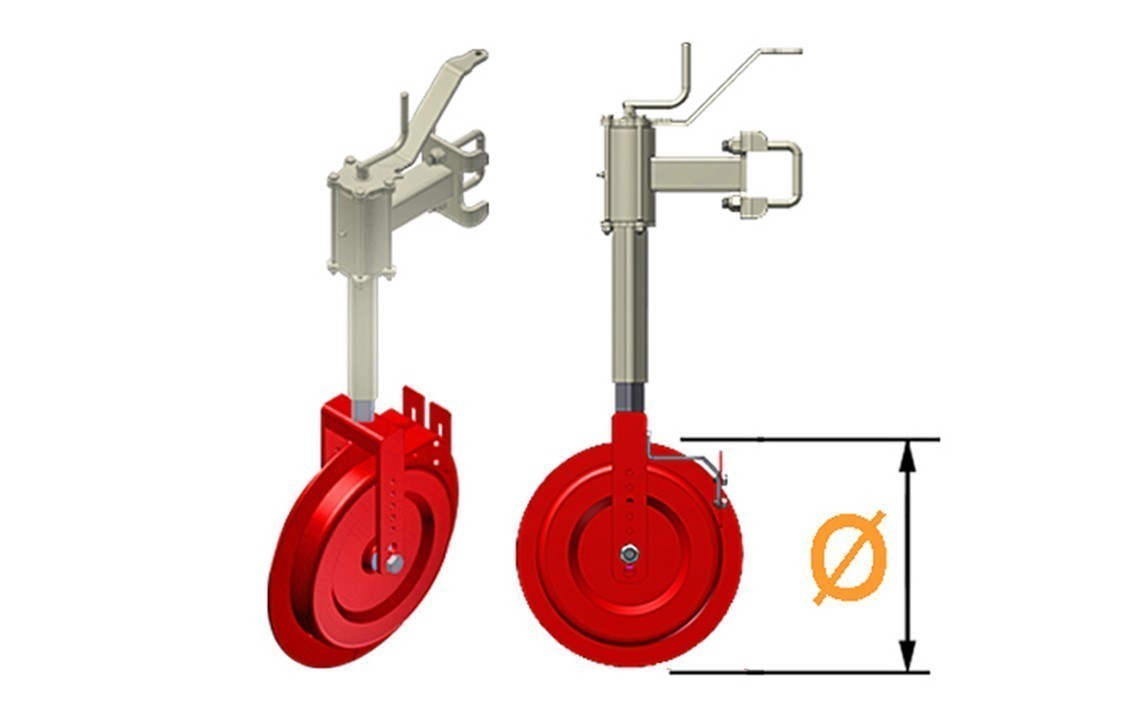

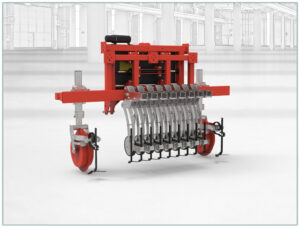

“FLEX” weeder with fixed or lateral-shift frame; modular design with multiple inter-row parallelogram units, equipped with support wheel and pressed hoe.

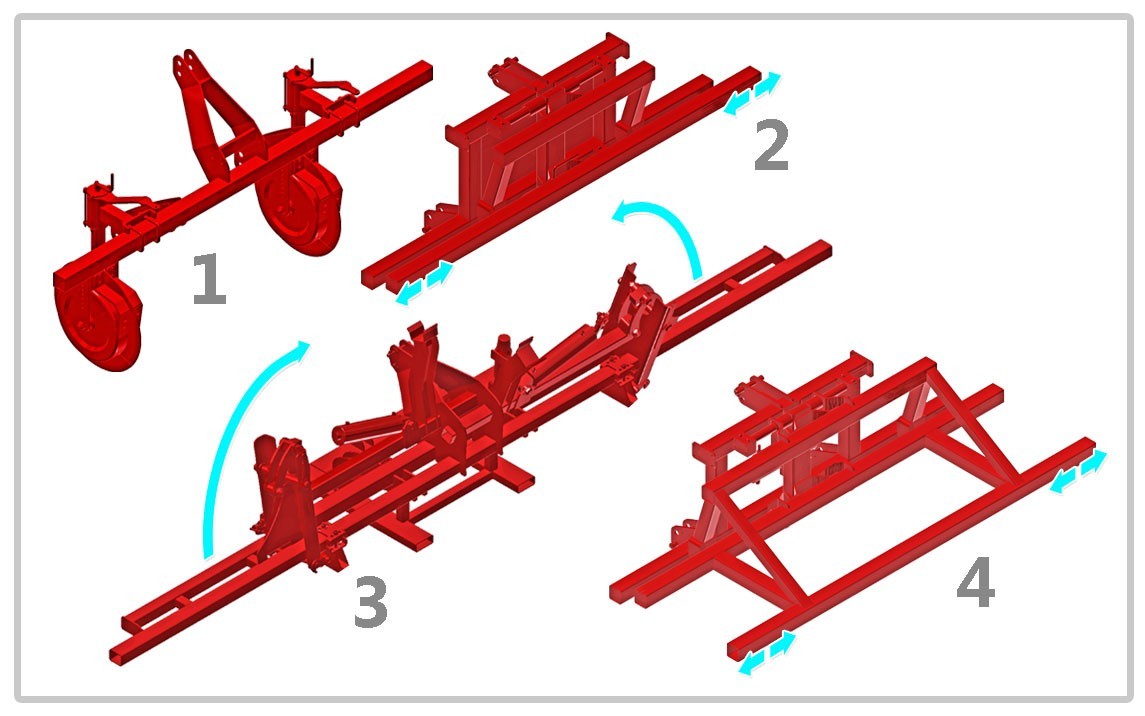

The FLEX weeder is the ideal solution for crops sown with row spacing between 14 and 16 cm, thanks to its lightweight and compact design. Developed for those who value speed and modularity, FLEX serves as the foundation of the ROTOVERT TILT weeder. This allows customers to start with a cost-effective investment and, depending on their precision needs and budget, upgrade at any time to the inter-row TILT module. A flexible, scalable choice—perfectly suited to a wide range of agronomic scenarios.

| TYPE OF SOIL | Sandy / medium-textured and stony soil (with small stones approx. 2–3 cm in diameter) |

| ROW SPACING | 14-16 cm |

| INTER-PLANT DISTANCE | – |

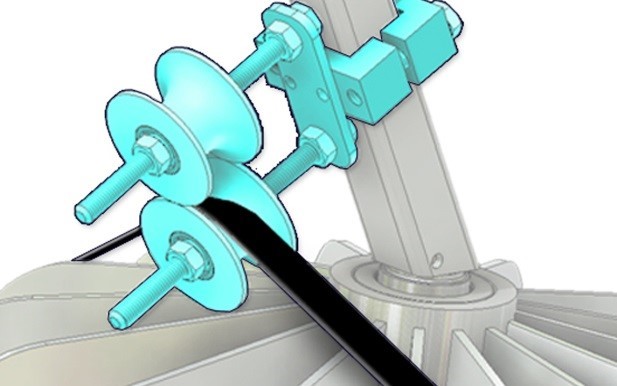

| ROTOR DIMENSIONS | No rotors – pressed hoe |

| WORKING SPEED | 4 – 8 Km/hr |

| REQUIRED PREPARATION OF THE LAND | Good |

| ROW N. | Depends on the seeder used |

| SYSTEM TYPE | Mechanic |

| USE | Intuitive and modular |