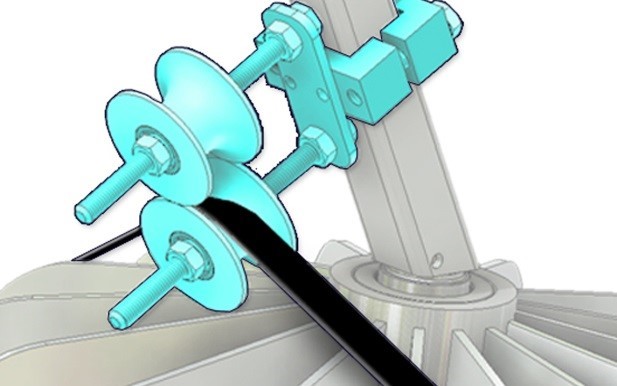

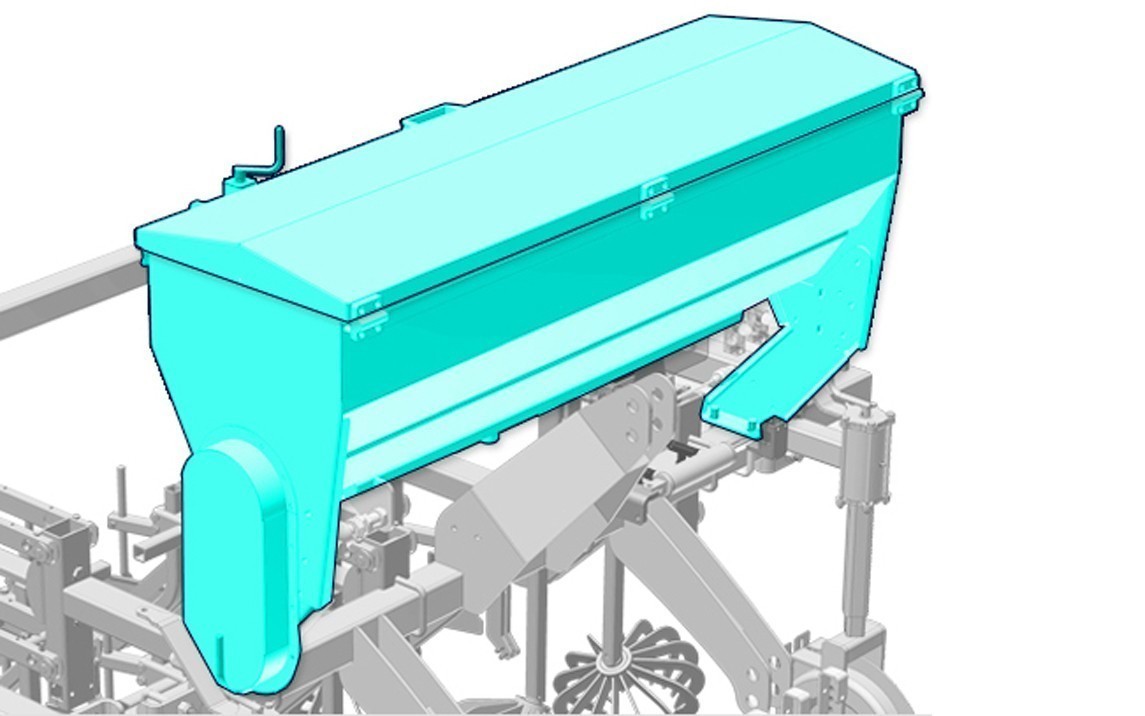

The “ROTOBRUSH” weeding machine is a simplified version of the Colibrì weeding machine that uses a brush system element instead of discs.

The “Rotobrush” weeding machine operates directly next to the sown row, just 2 cm from the plant, and is suitable for crops sown on ridges or raised beds with minimum inter-row spacing of 15 cm. It works without damaging the root or leaf systems, prevents weed germination, and is ideal for false sowing or use in stony soils.

Thanks to its active weeding action provided by the motorized rotation of the brushes, “Rotobrush” finely crumbles and levels the soil without displacing the plants. The speed and configuration of the brushes can be adjusted and customized based on the plant’s growth stage and soil type.

| TYPE OF SOIL | Sandy, medium-textured, with small stones |

| INTER-ROW DISTANCE | Minimum 15 cm |

| INTER-PLANT DISTANCE | – |

| SOWING/TRANSPLANTING | Centered on raised beds and ridges |

| WORKING SPEED | 1.5 – 3.5 Km/h |

| REQUIRED PREPARATION OF THE LAND | Bed former with smooth leveling roller; use of RTK GPS for soil preparation, sowing, and weeding |

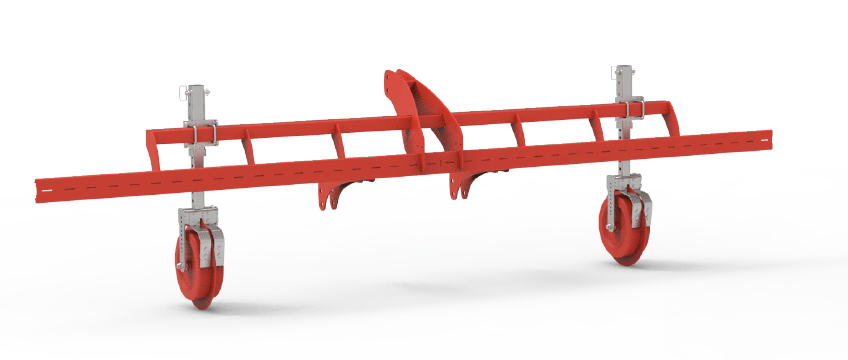

| ROW N. | Depends on the seeder in use, working on one bed or multiple ridges at a time |

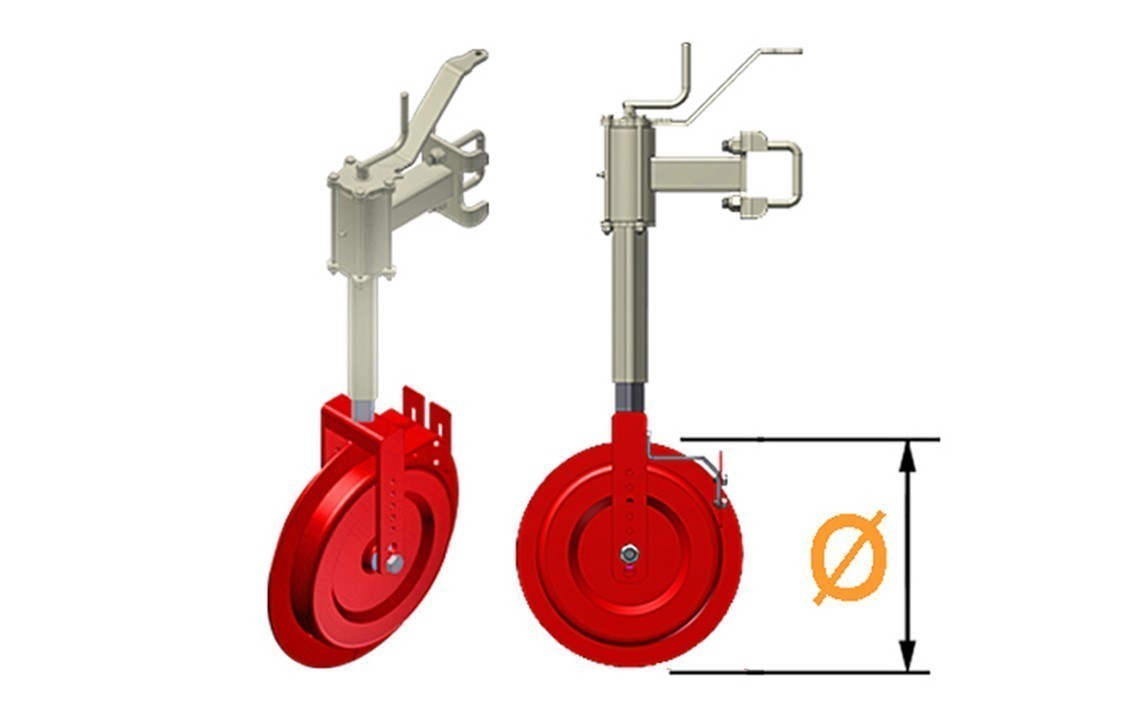

| SYSTEM TYPE | Hydraulic |

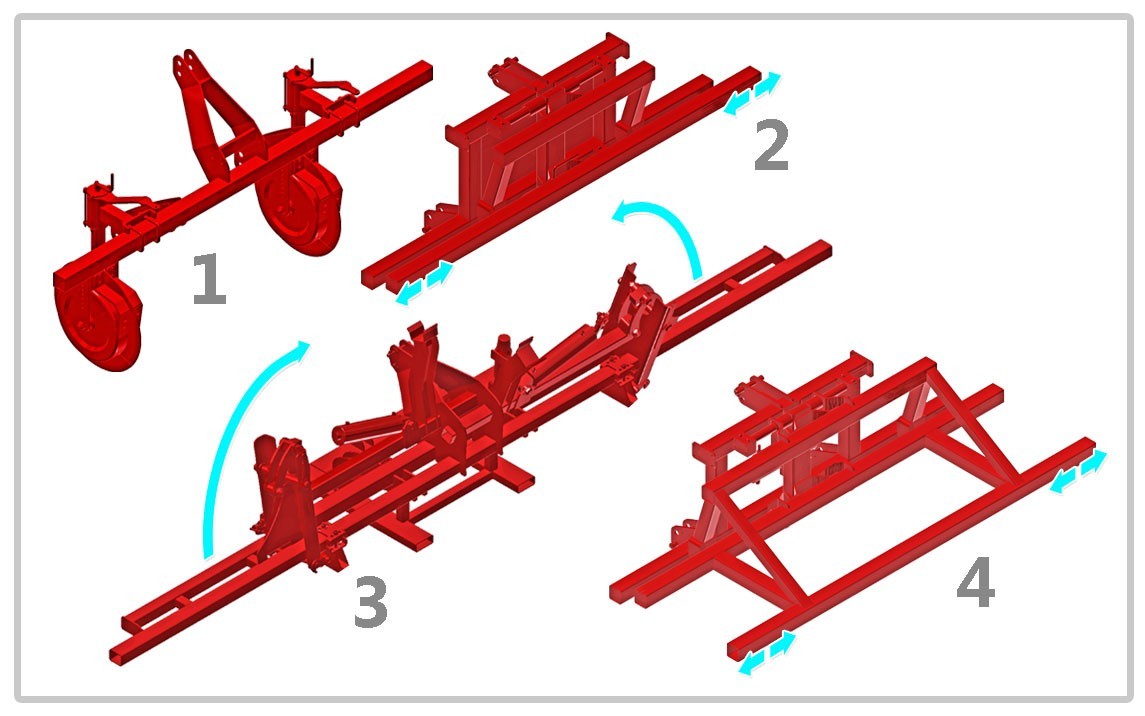

| USE | Intuitive and modular |