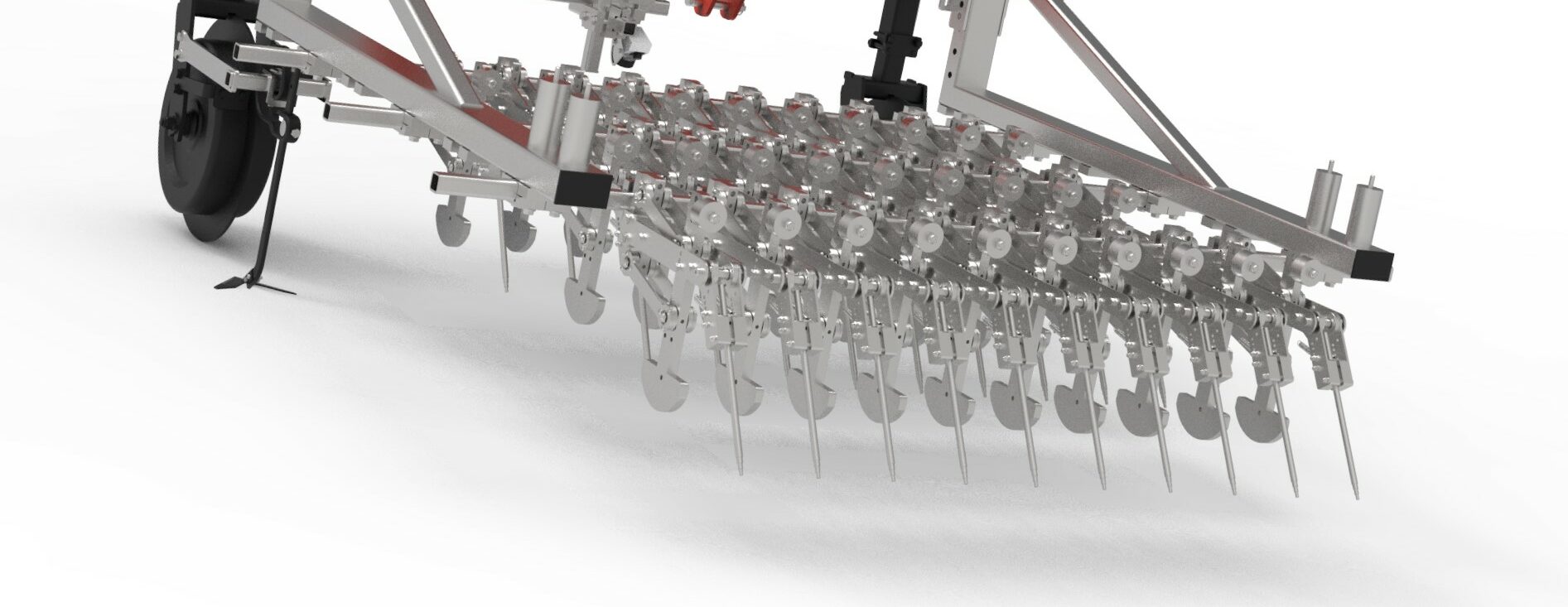

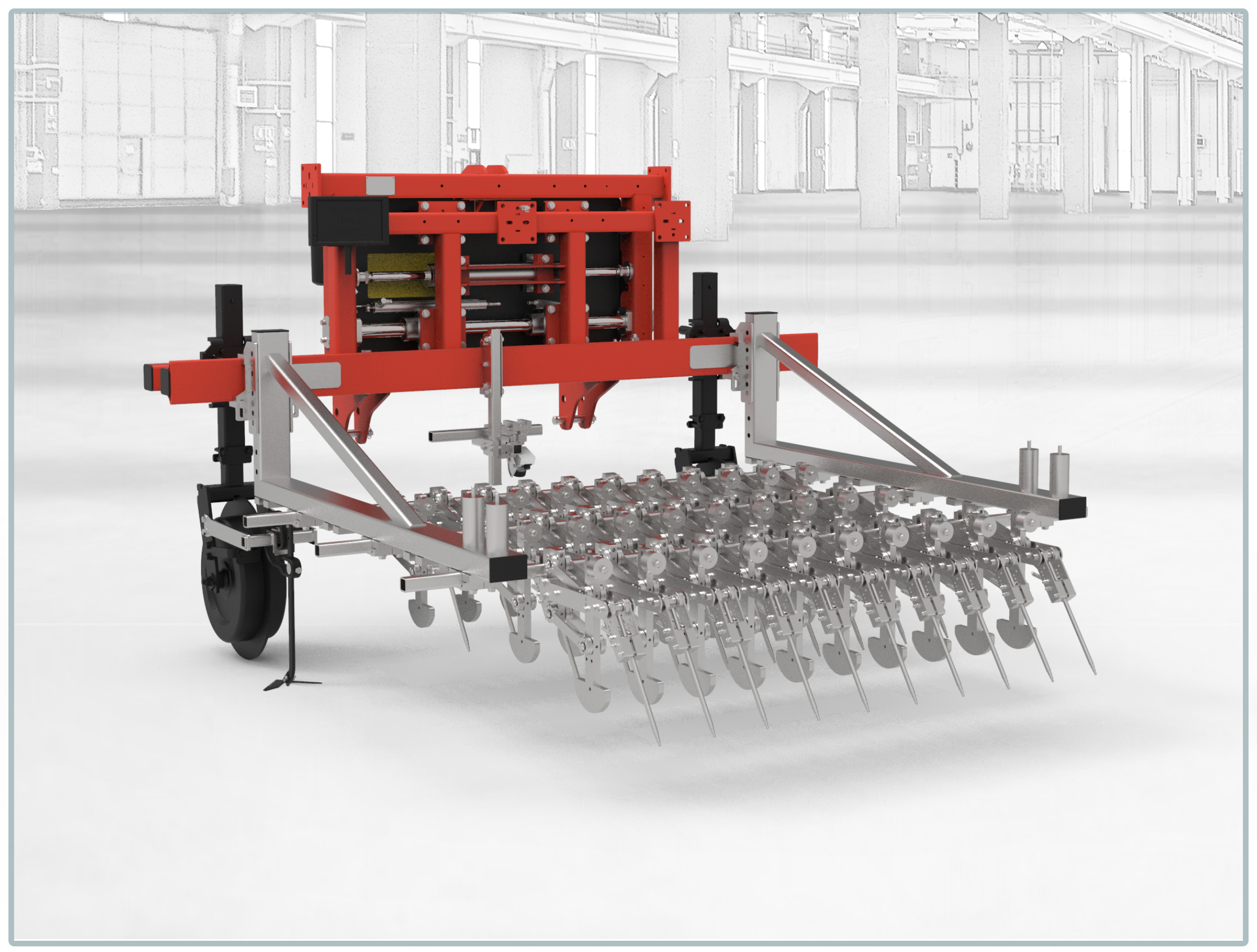

“STRIG” weeding machine with fixed or sliding frame; configurable with multiple inter-row parallelogram elements equipped with support wheels for inter-row cultivation

The STRIG inter-row weeder is designed to operate on narrow inter-row spacings starting from 6 cm, typical of baby leaf crops or closely sown species such as basil. Thanks to its compact and modular structure, it can be used during the early growth stages of the crop, even on silty soils with moderate presence of stones—conditions where the Colibrì weeder cannot operate.

Each STRIG element is independent and mounted on offset bars, a configuration that allows for precise alignment with the sowing rows while keeping overall dimensions compact.

Each element consists of:

-

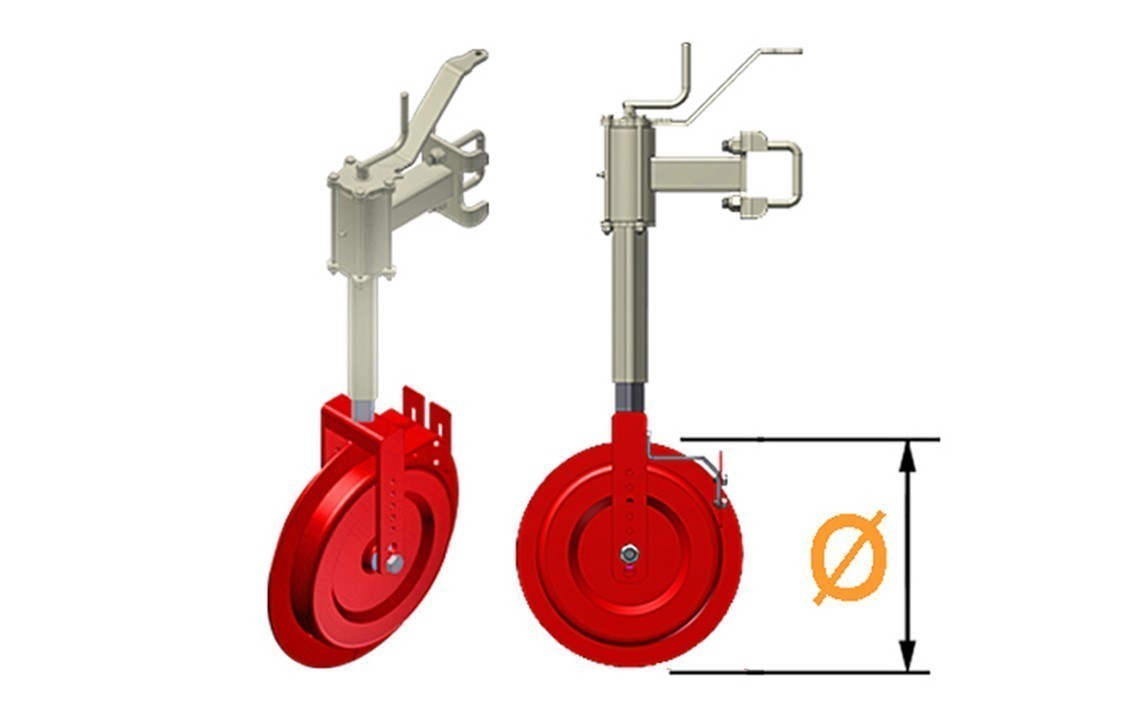

a support wheel to ensure consistent working depth,

-

a tine or interchangeable disc that works directly in the inter-row space.

The tools can be adapted according to the crop, its growth stage, and the soil type (including stony soils).

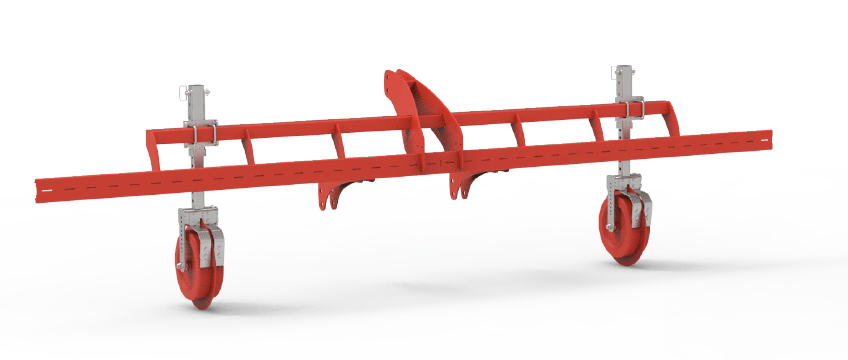

The frame is available in two versions:

-

Hydraulic version with lateral translation, equipped with an automatic camera system for active row guidance,

-

Operator-controlled version, with seat and joystick for manual steering.

| TYPE OF SOIL | All soil types with few small stones |

| ROW SPACING | 5 – 8 cm |

| INTER-PLANT DISTANCE | – |

| ROTOR DIMENSIONS | To be evaluated after soil analysis |

| WORKING SPEED | 3 – 6 km/h |

| REQUIRED PREPARATION OF THE LAND | Good |

| ROW N. | Depends on the seeder used |

| SYSTEM TYPE | Mechanic |

| USE | Intuitive and modular |