Bedformer machine – Mod. BXC

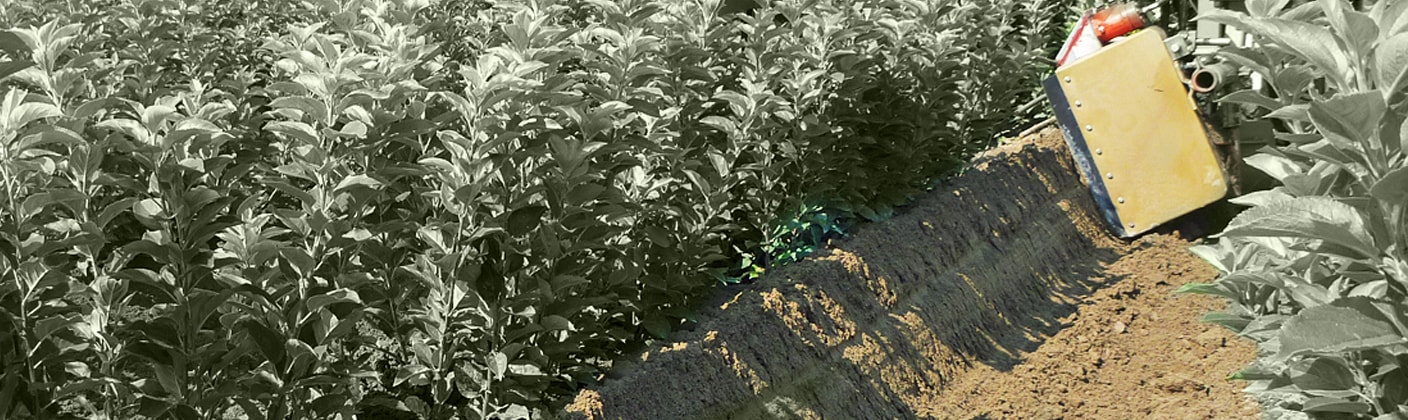

The Bedformer Mod. BXC is an indispensable machine for the creation of the motherplant’s bed.

Allows the progressive accumulation of soil and is useful for cleaning the ridge.

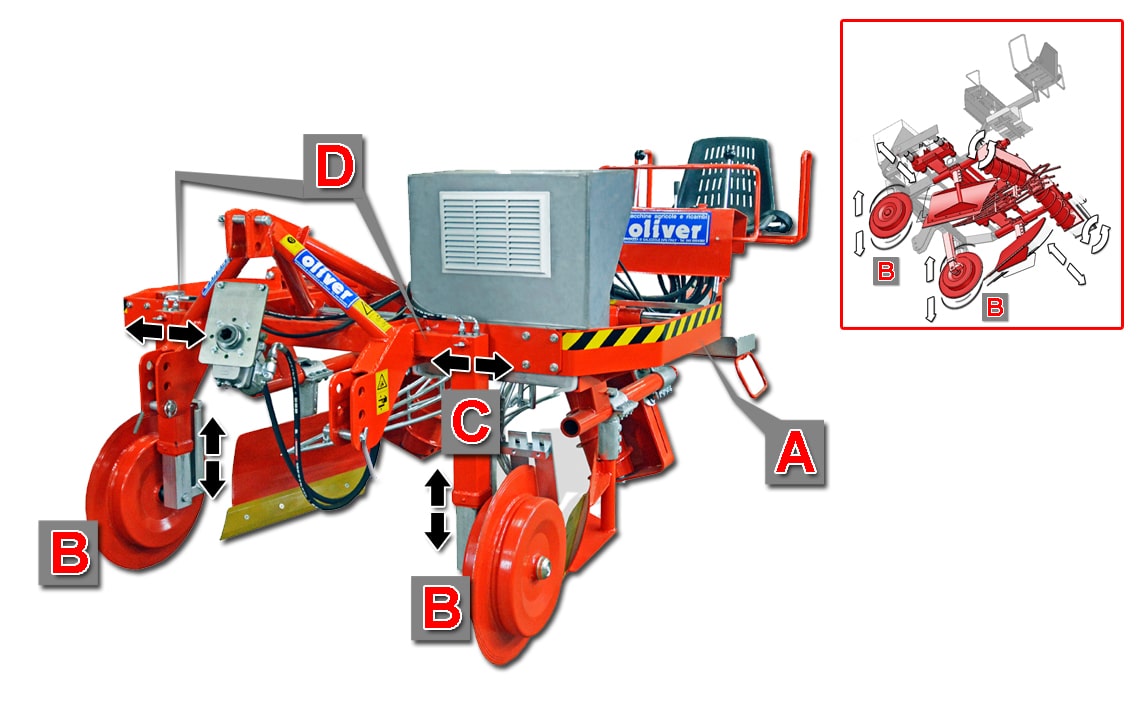

Bed former: versatility for bed making, weeding and preparation for uprooting.

The offer of Oliver Agro bed formers

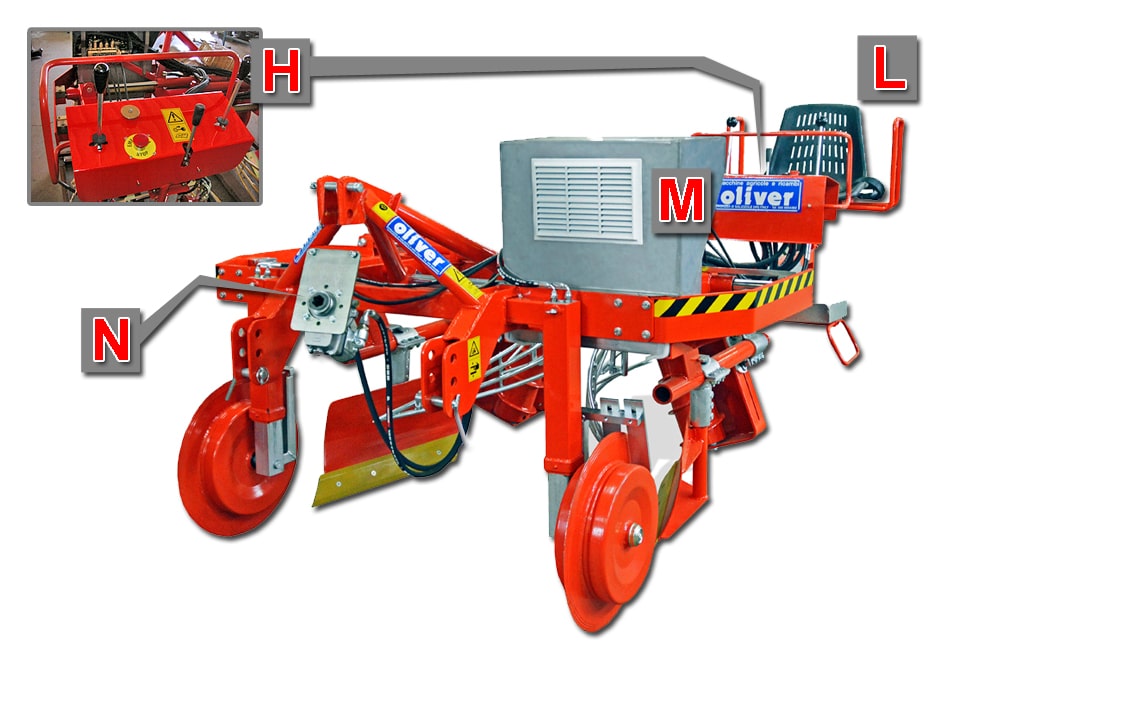

Oliver Agro has over 20 years of knowledge of the production of agricultural machinery in fruit trees nursery. The BXC bed formers, the TXC seedling uprooting machine and the SXC brushing machine have been designed for an ultra-specific supply chain, related to motherplants or wild rootstocks.

BXC Bed former: technical specifications

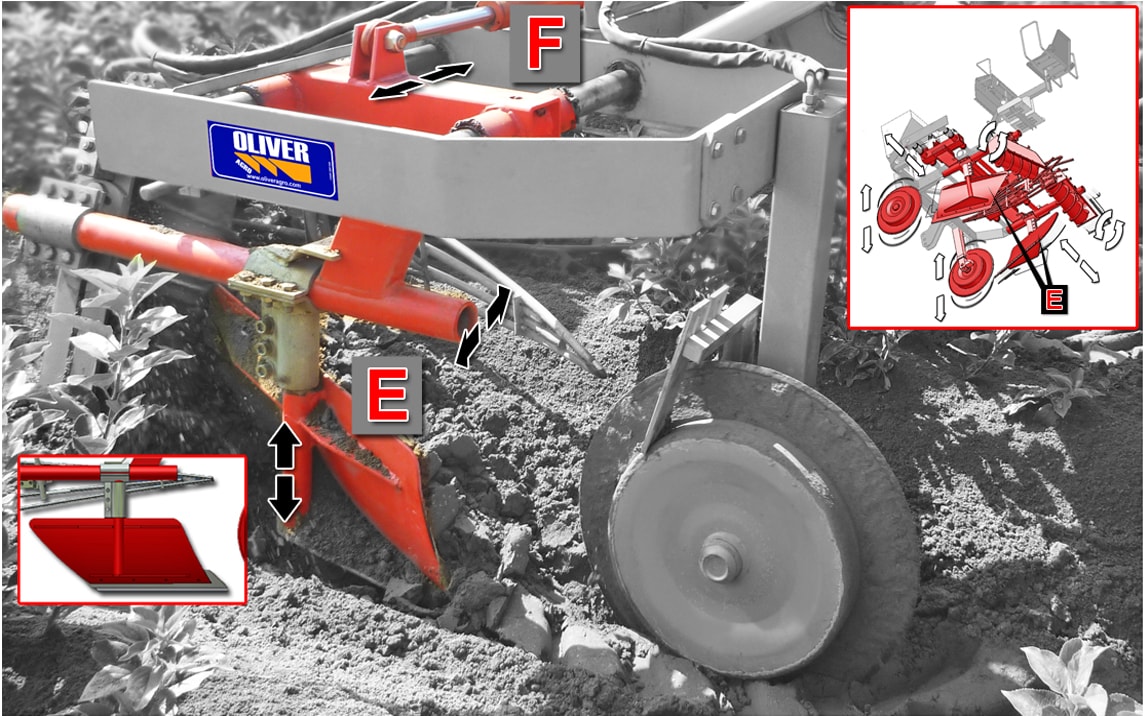

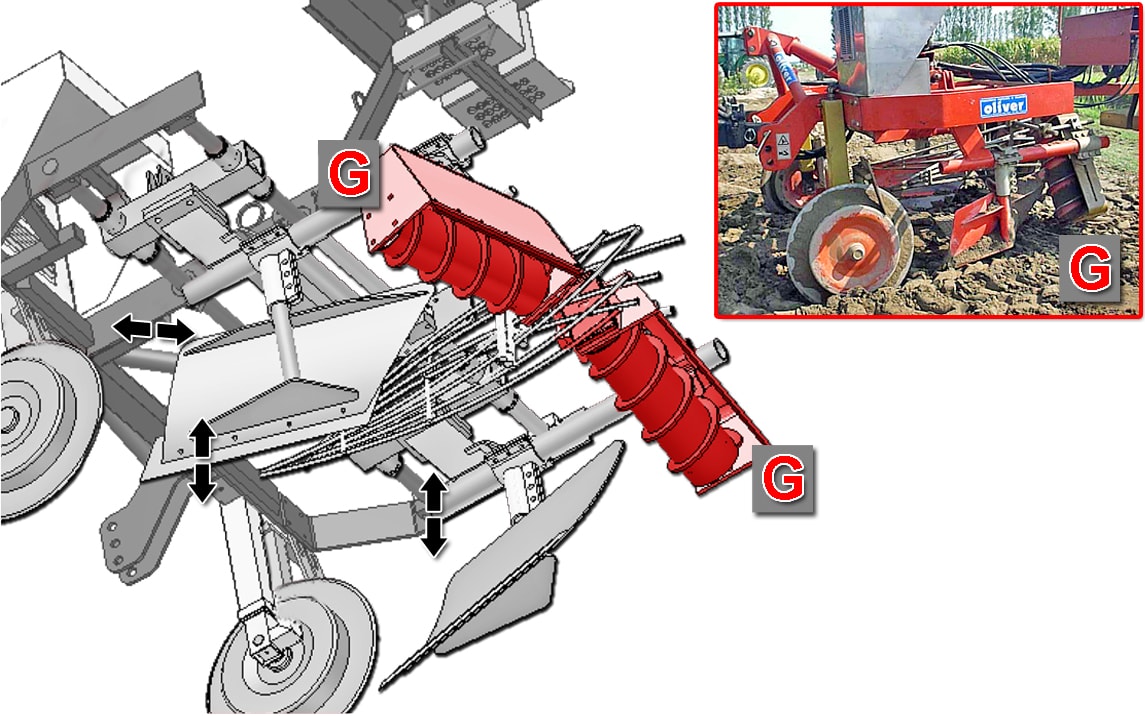

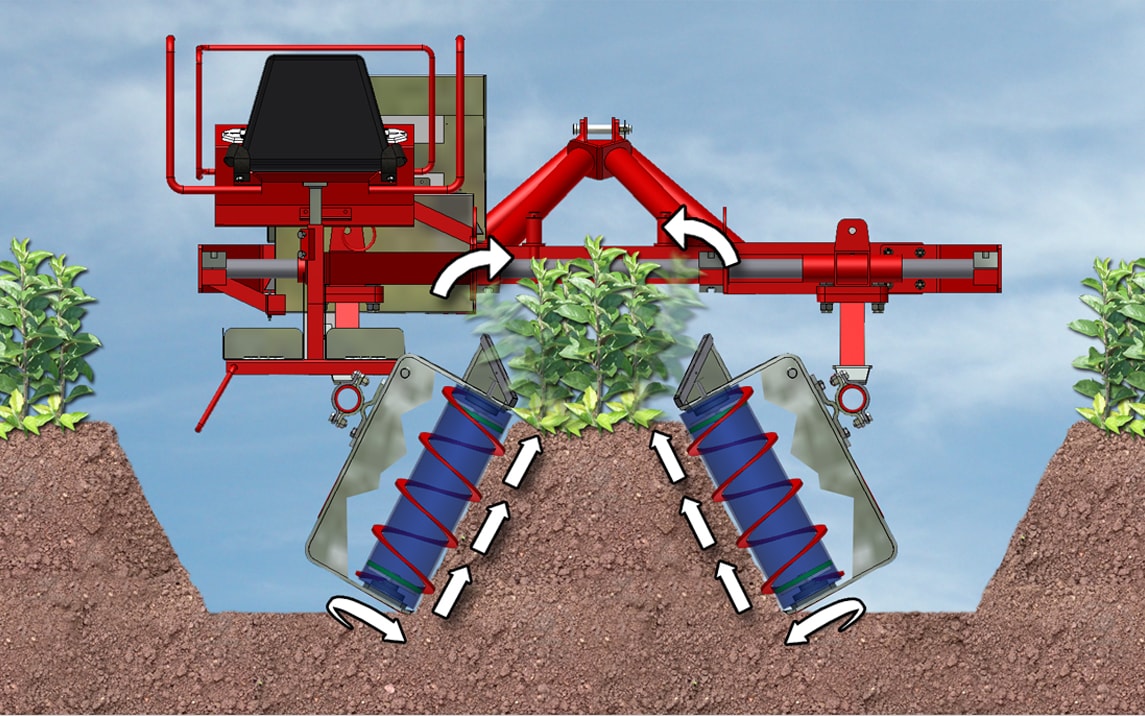

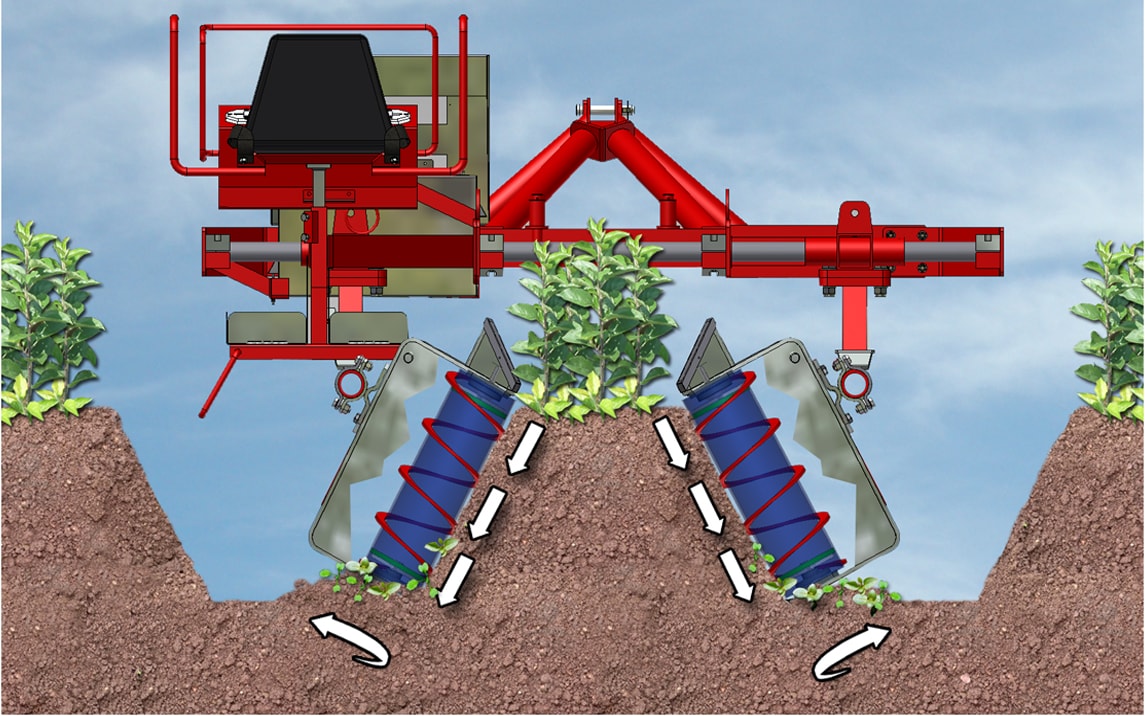

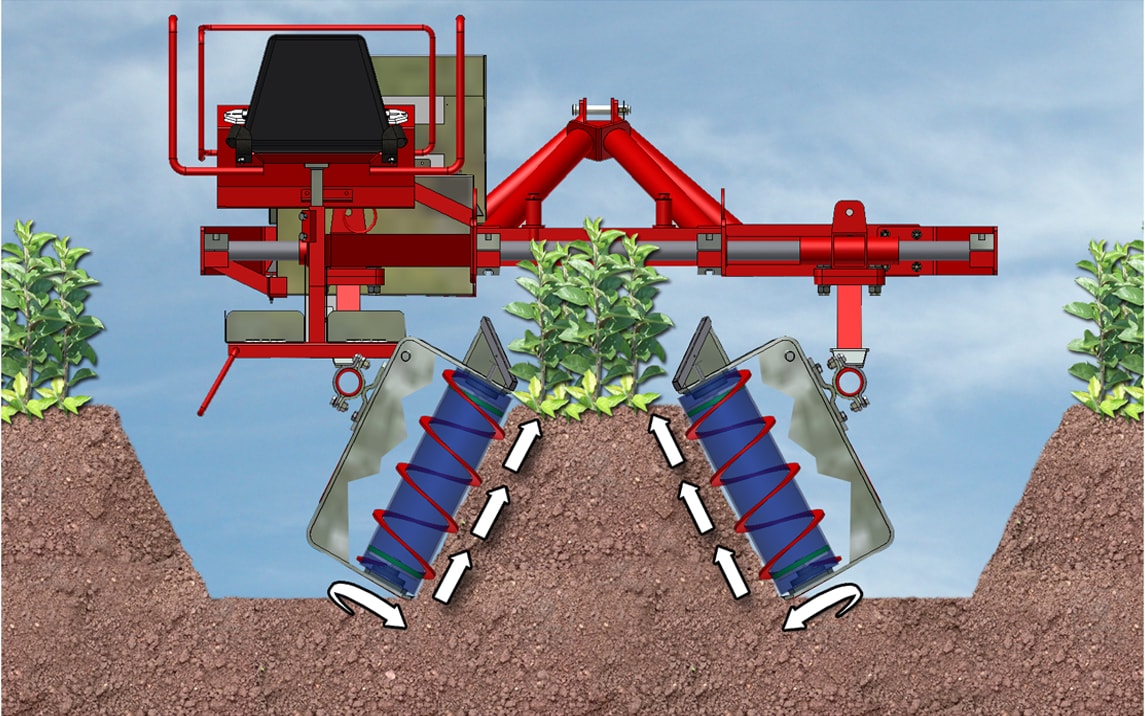

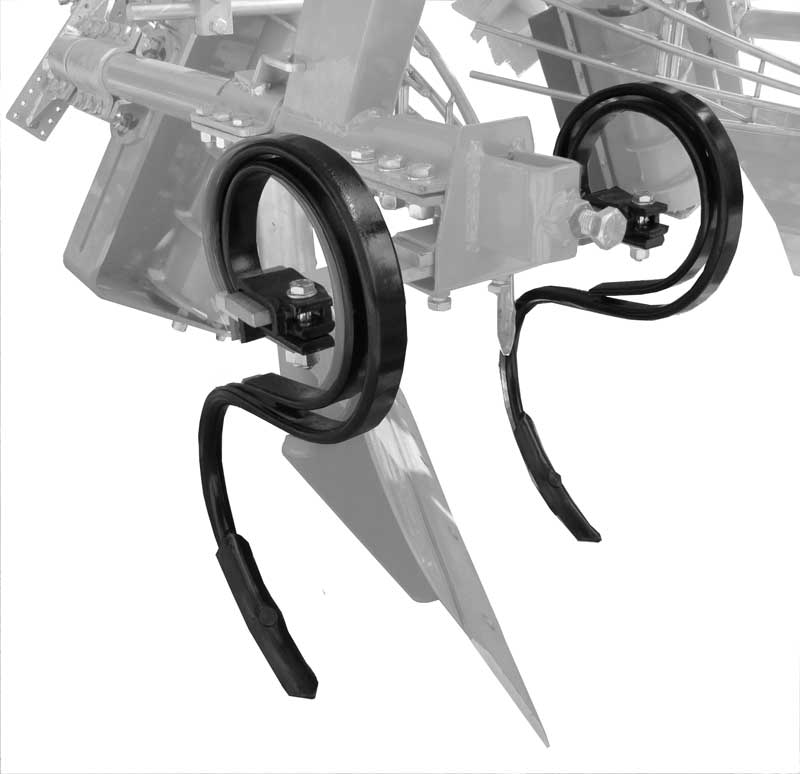

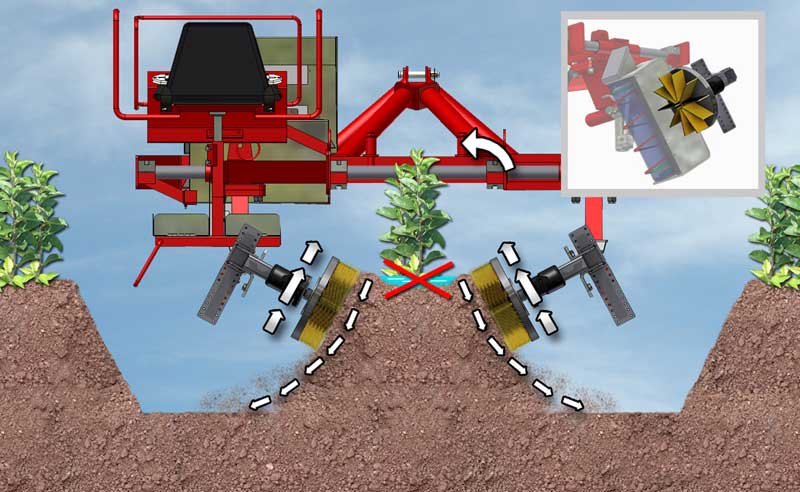

Bed former BXC’s main functions proposed by Oliver Agro company are: progressive creation of ridge for the motherplant, cleaning of backsides of bed and its earthing up. To obtain these results, the machine is equipped with plowshares that convoy soil to the center. At the same time, the two rotating cochleae carry out three distinct operations: their angle is modeling the bed’s desired shape, push the soil ground towards the top from the sides, obliging the roots to be straight. When inverted their rotation, they push 2 cm of soil down as weeds’ removal. Once the cycle has been completed, the bed former, reversing the plowshares’ direction, works as a remover, to facilitate the cutting of the rootstocks with the TXC uprooting machine.

CATÁLOGO EN ESPAÑOL

CATÁLOGO EN ESPAÑOL