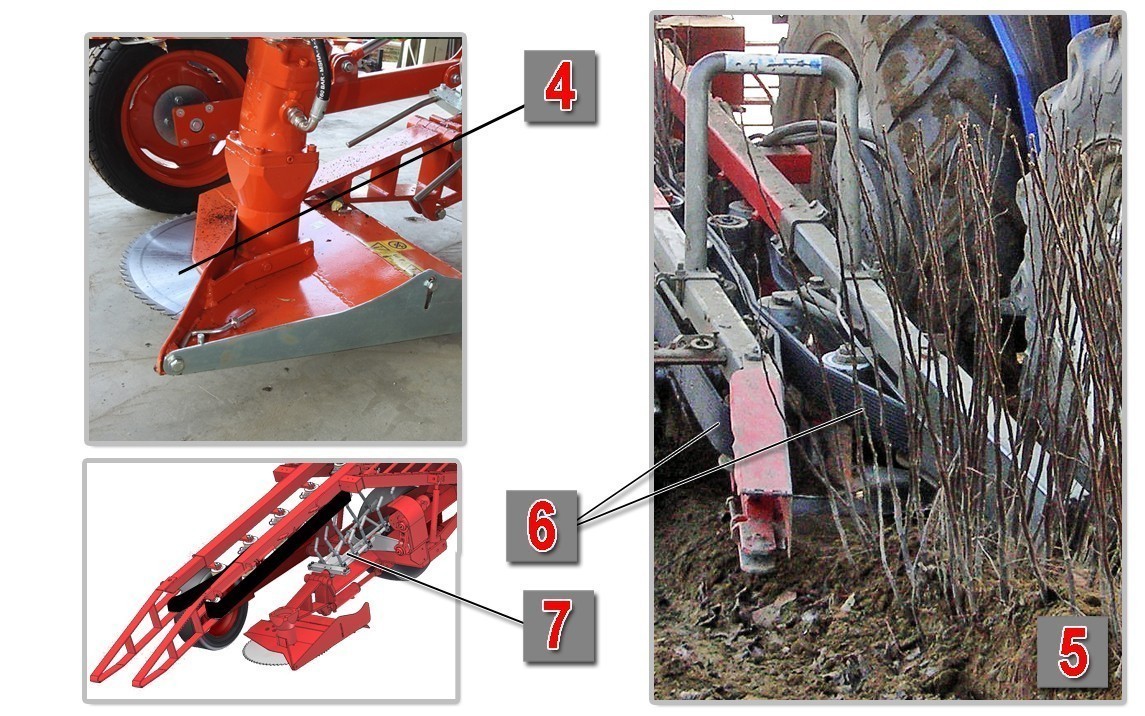

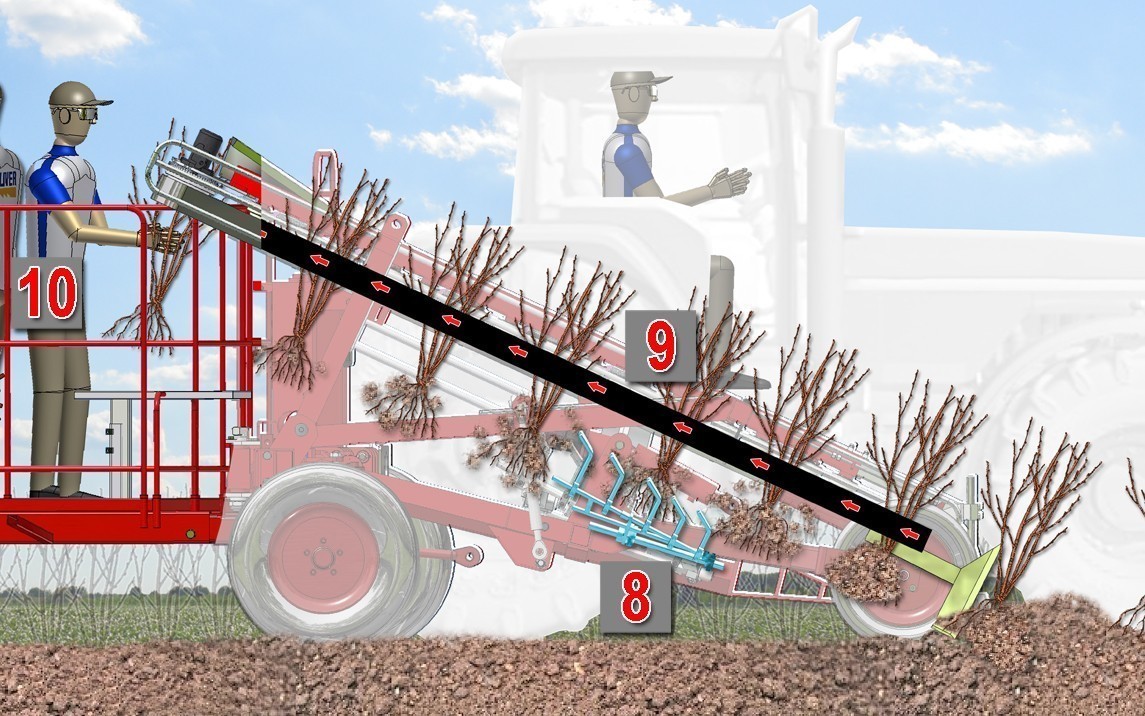

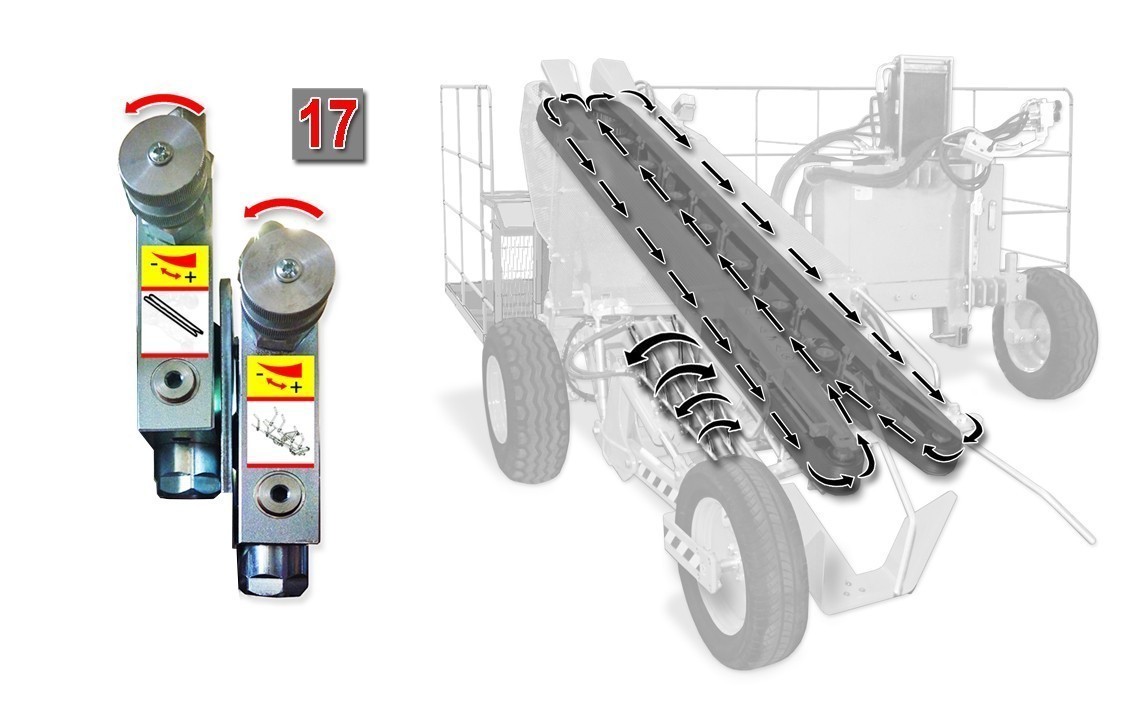

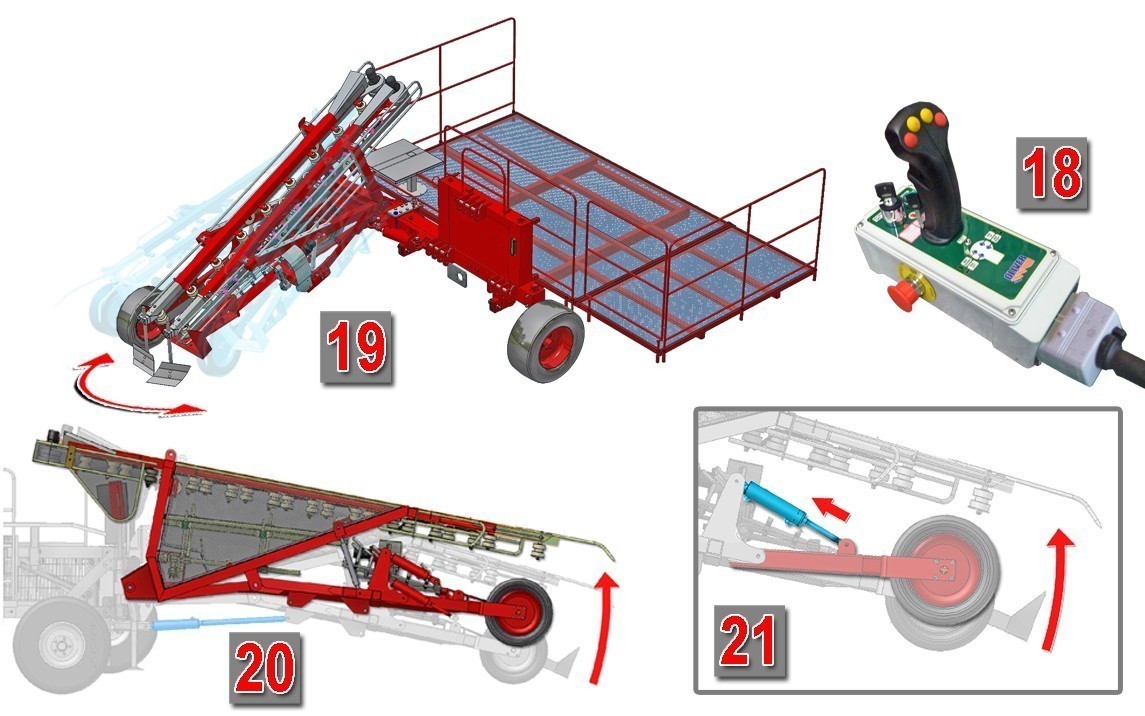

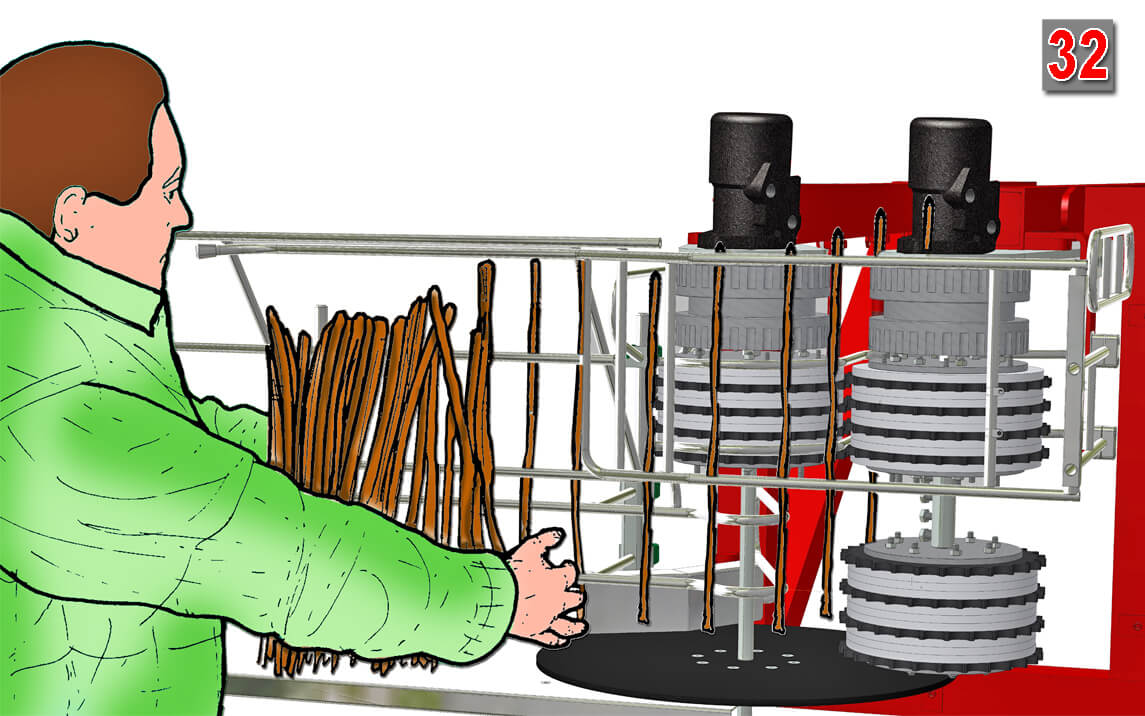

The SP2000 TXC harvester machine, thanks to the 600 mm Widia cutting disc (4), driven by a powerful hydraulic motor, cuts the wild graft rack holder (5) and, simultaneously, the conveyor belt (6), intercepts the stem of the plant, dragging it towards the shaker (7).

Cutting circumference: disk diameter =600 mm rpm 1800, Widia LITTLE teeth. D. 600X4,5X35 Z=72

This disc was choose also for its weight (6.5 kg) and for the form of little and numerous (72) fine-tooth in widia, material that keeps the sharpening and a perfect cut without tears.

Our disc cut and create sawdust, we advise to combine the use also of the brushing machine.

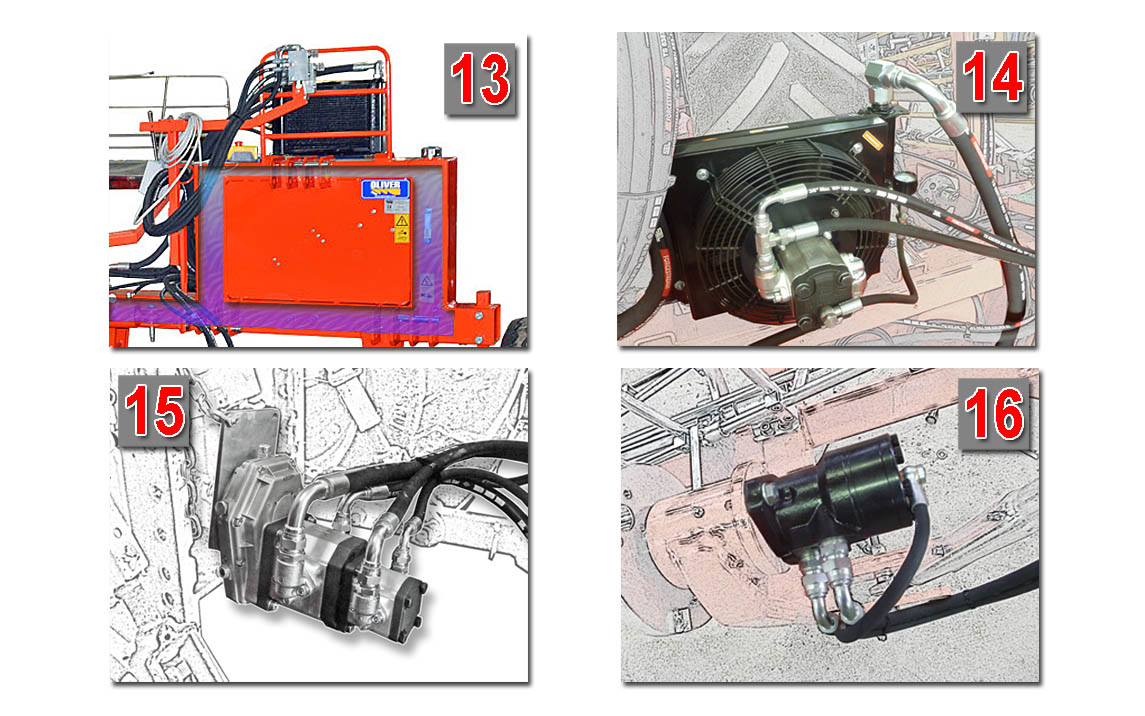

The motor and pump chosen are a piston ones. Very high powerful for the cut, with steady RPM (revolutions) and torque for all type of soil. This keeps high quality on the cut and stability to the cut, we don’t have any vibration on the motherplant and movements to the root system.