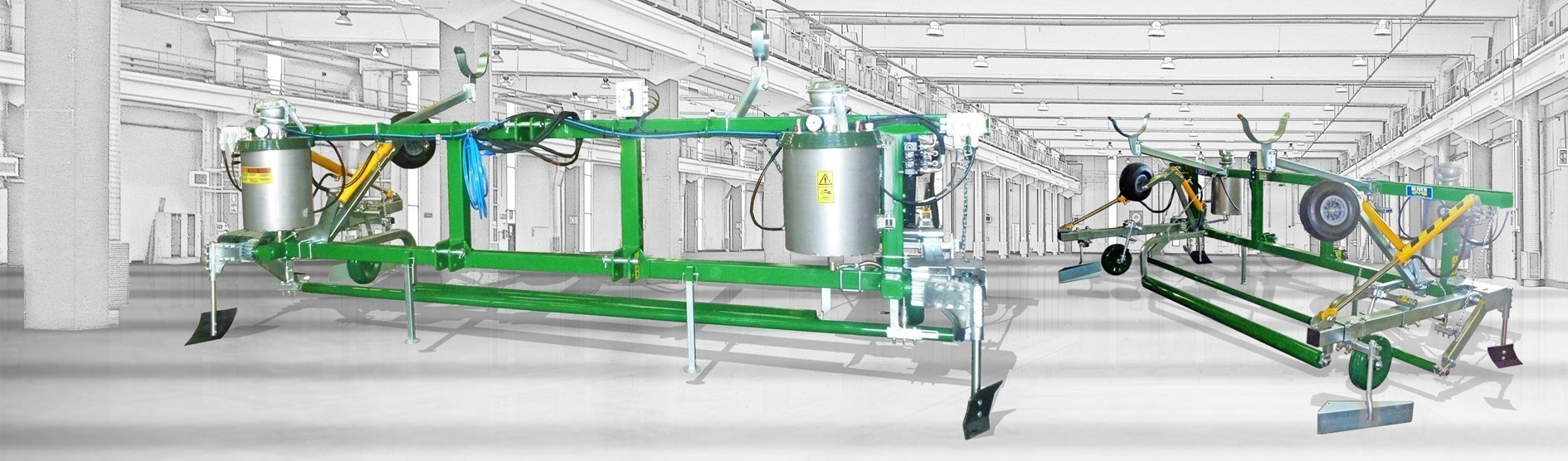

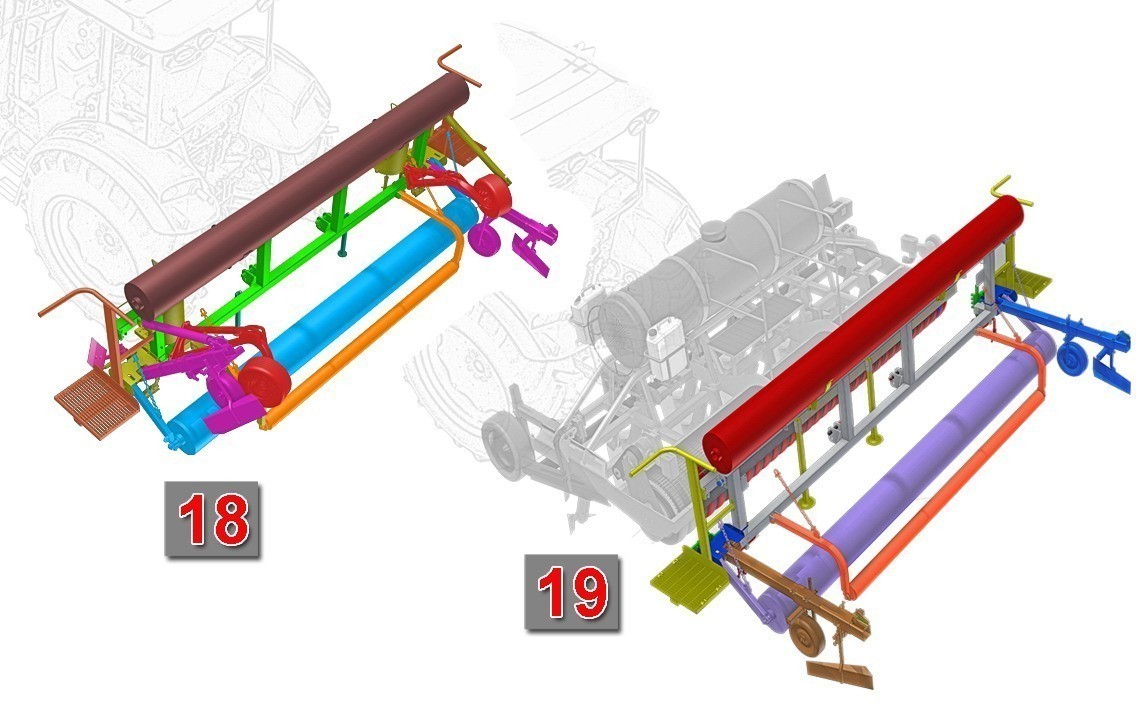

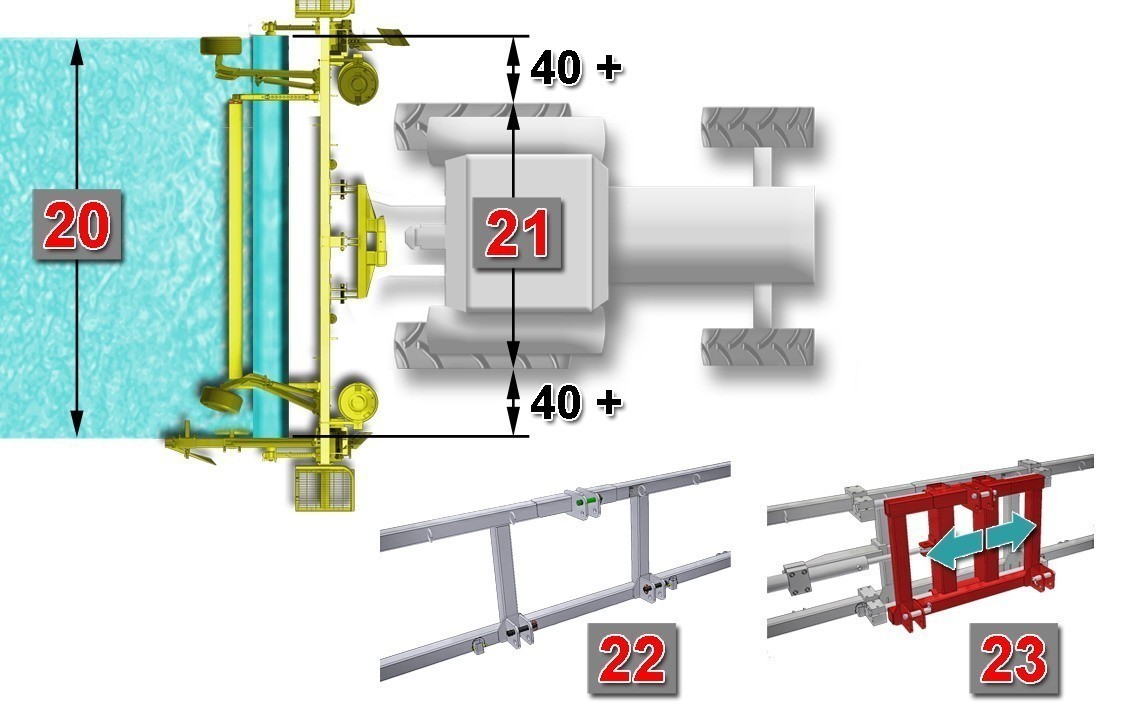

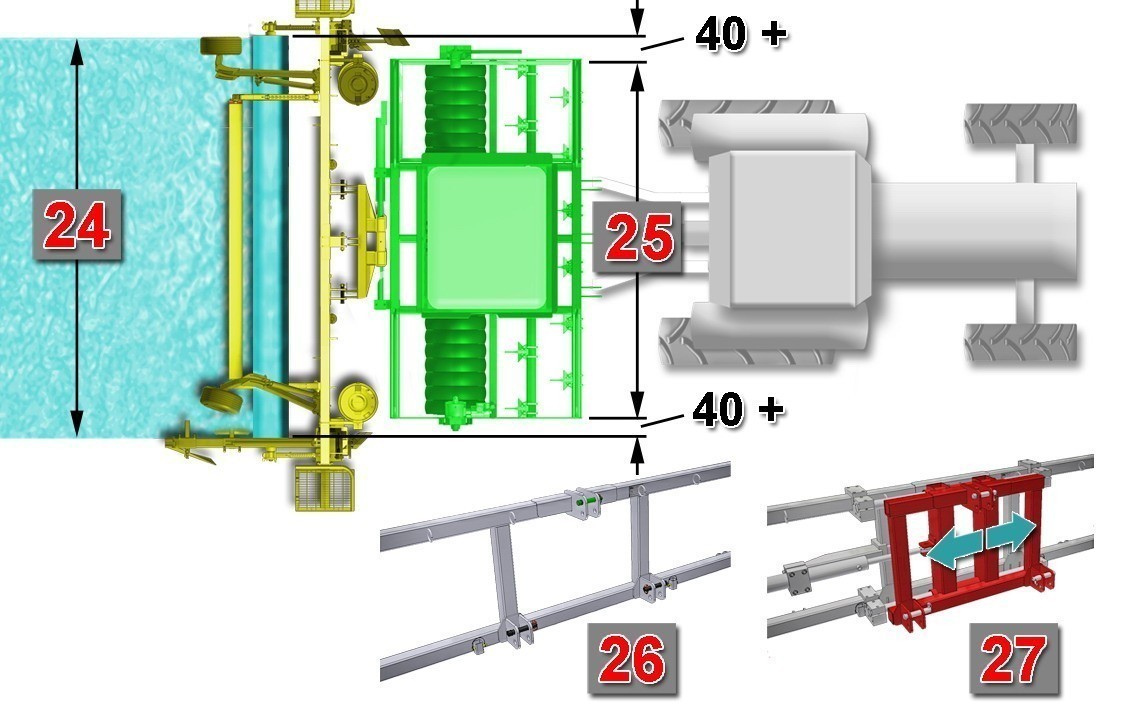

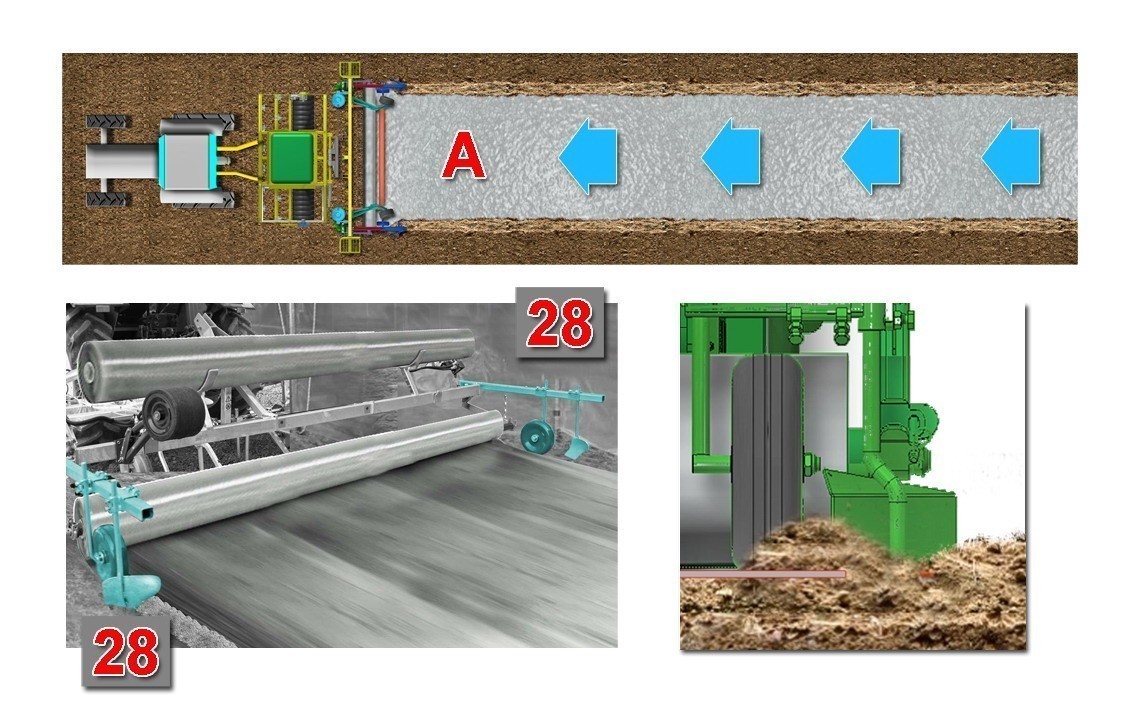

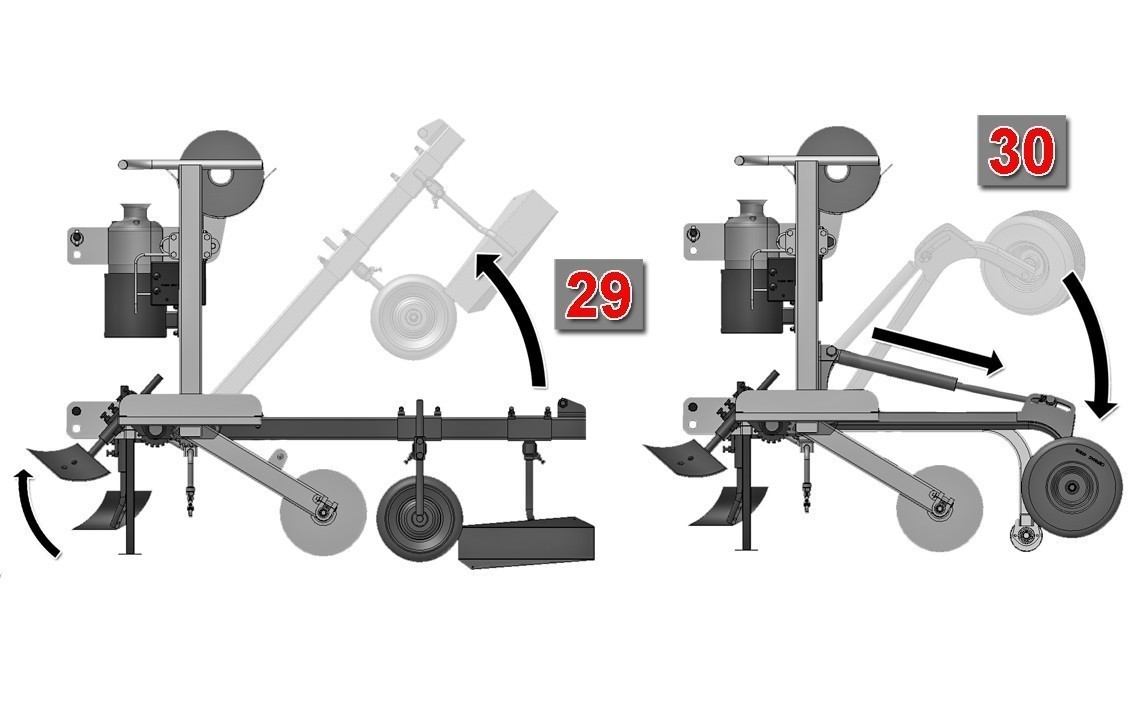

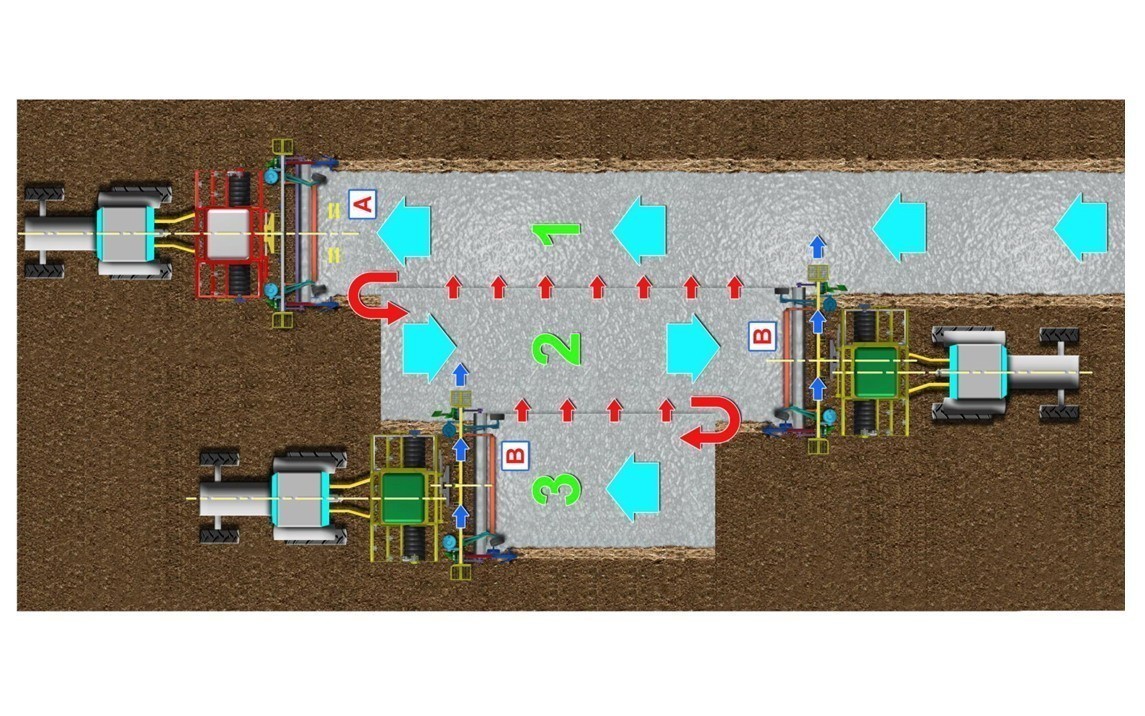

The Gluing and layer machine for barrier film is a trailed machine that, thanks to its applications, performs

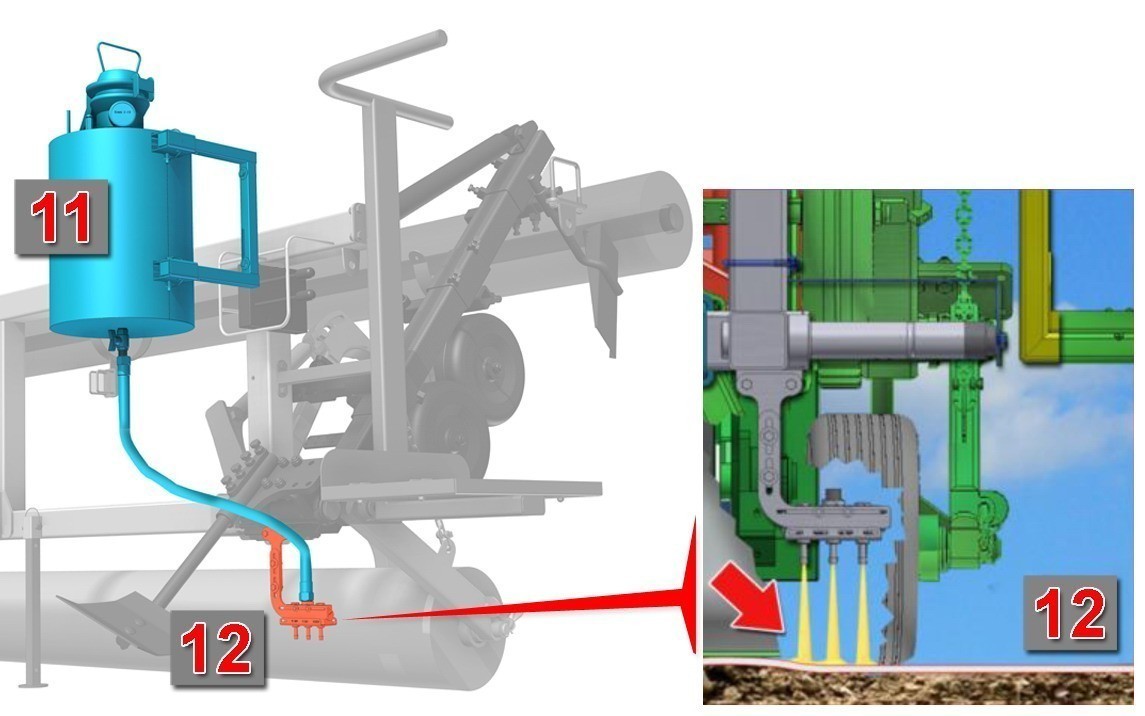

– the laying of barrier film

– the film for solarization

– mulching

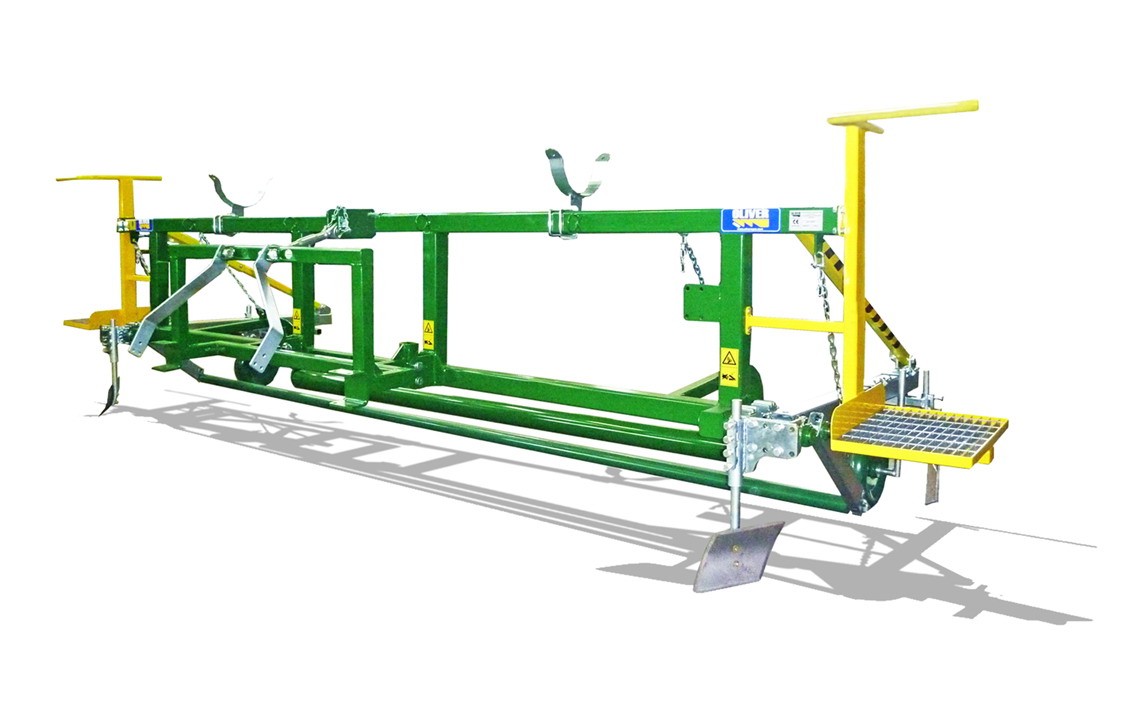

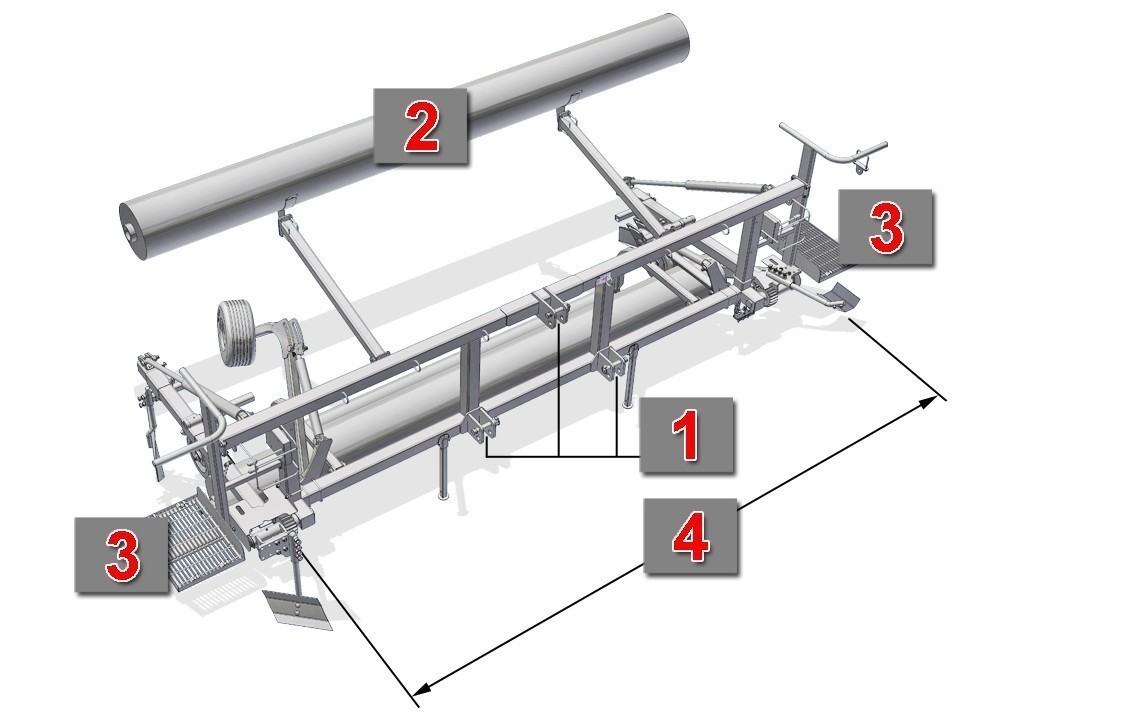

Mulching Film Layer

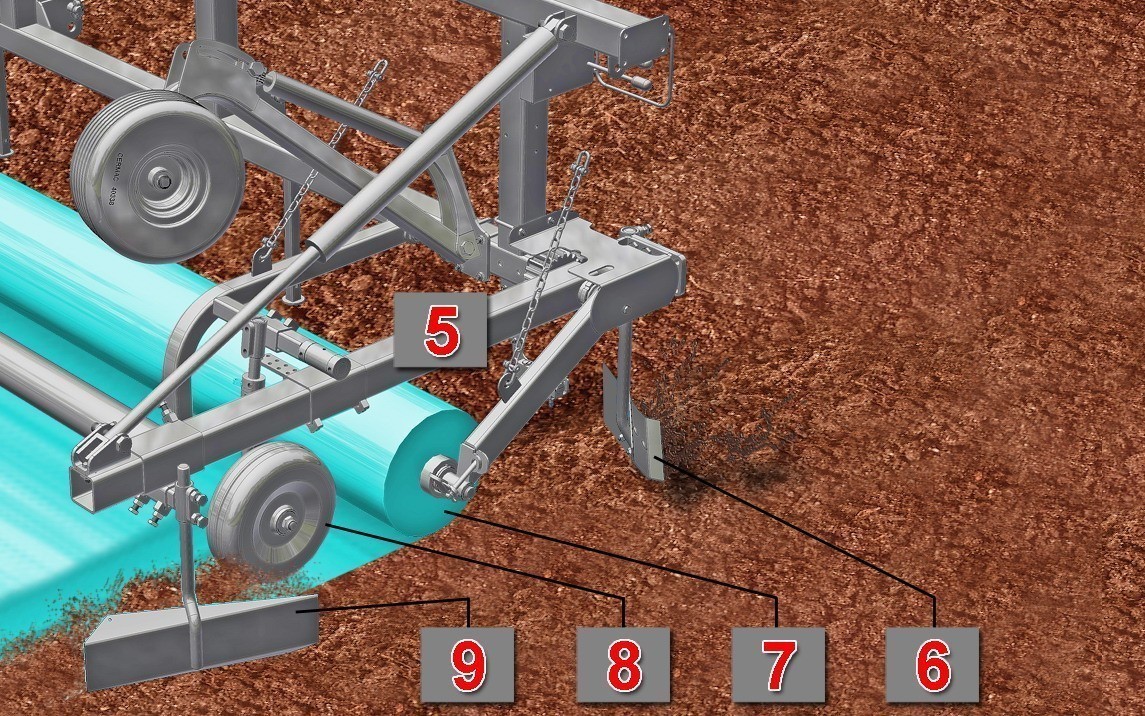

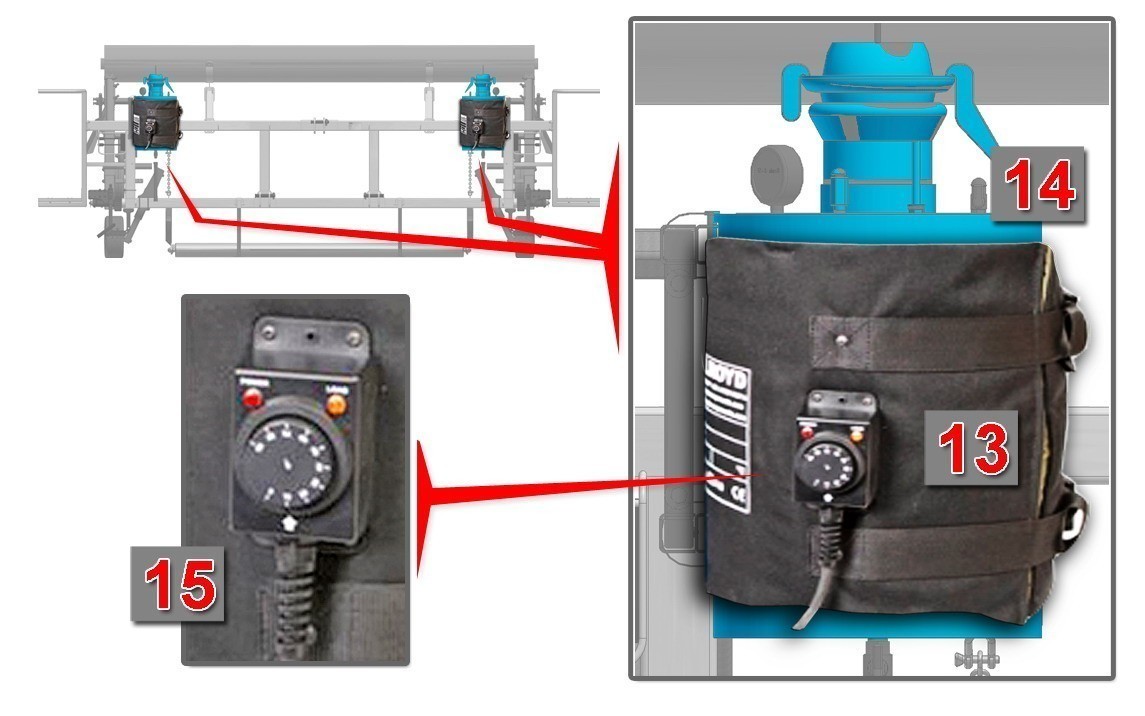

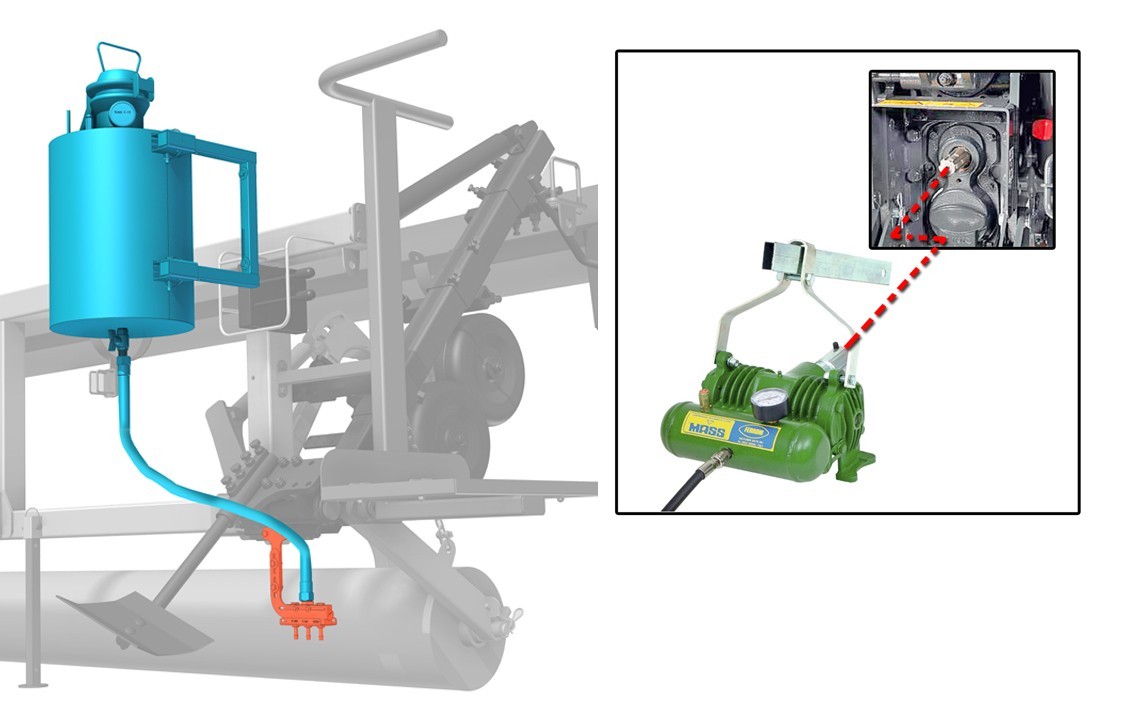

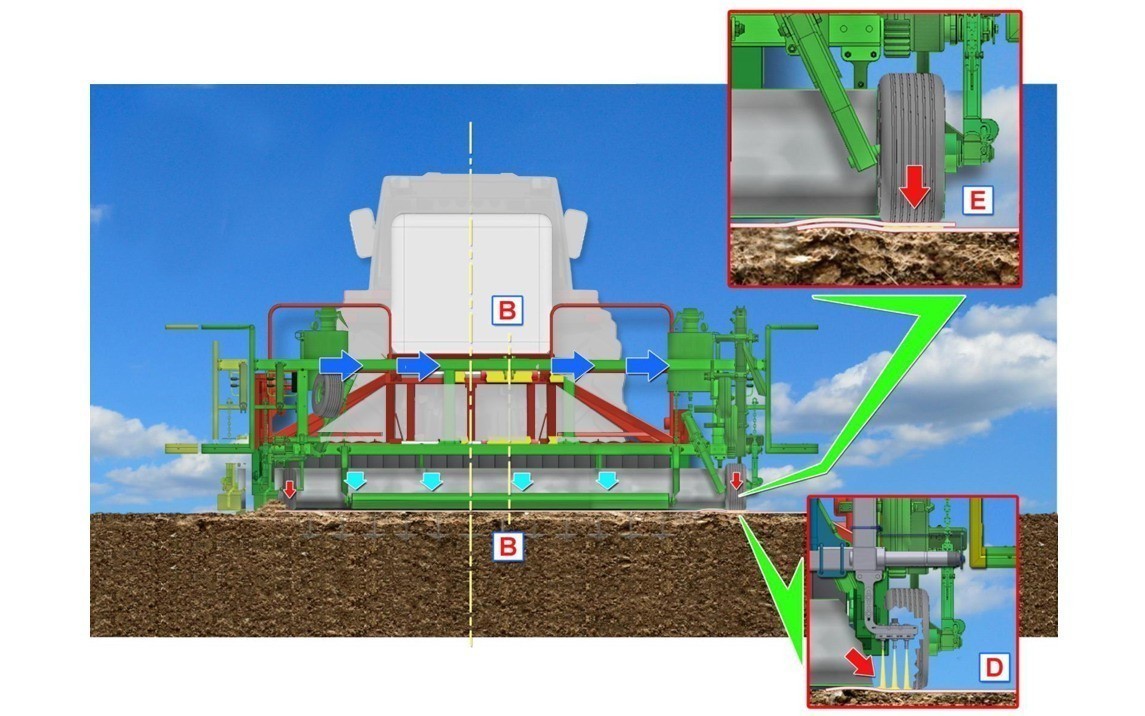

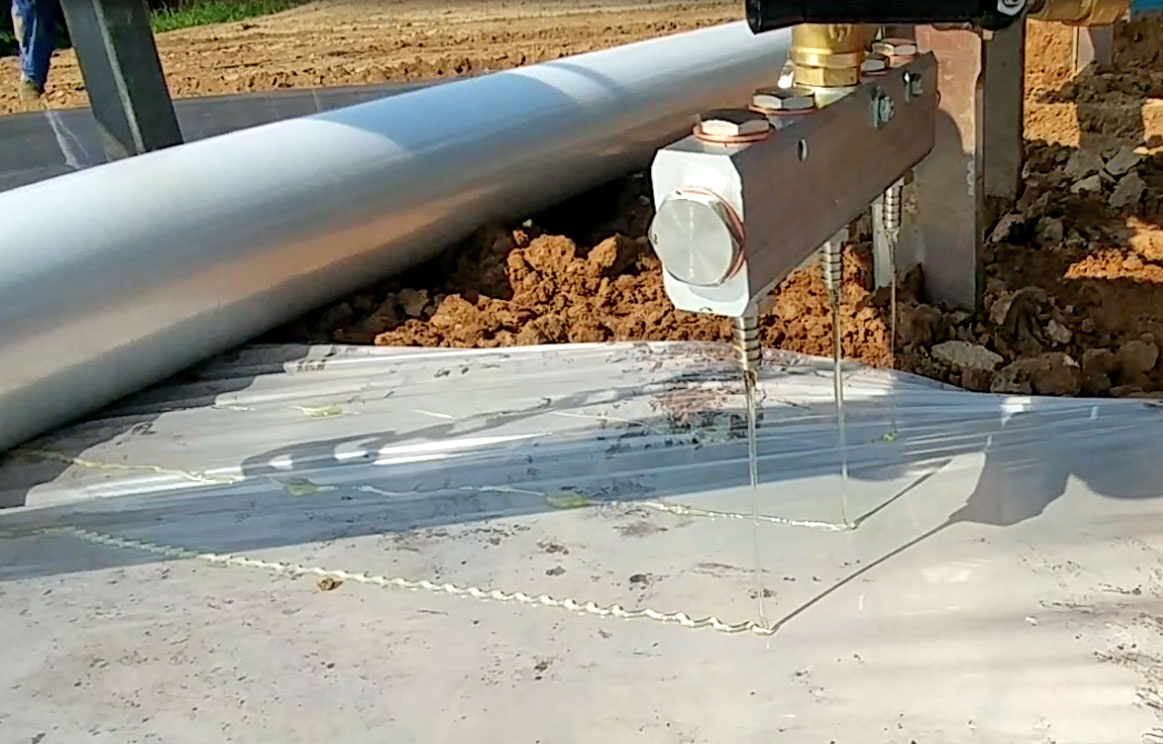

It guarantees excellent results in sealing the soil, thanks to a precise laying of the nylon film.

Oliver Agro company’s Mulching Film Layer is a mulching machine, used to uniformly spread the protective film, in particular TIF or VIF, sealing it with a special glue to avoid dispersion of fumigating product in the atmosphere. Thanks to the Oliver Agro Mulching Film Layer, it will be possible to obtain an hermetic seal and the consequent solarization, which also acts as a herbicide.