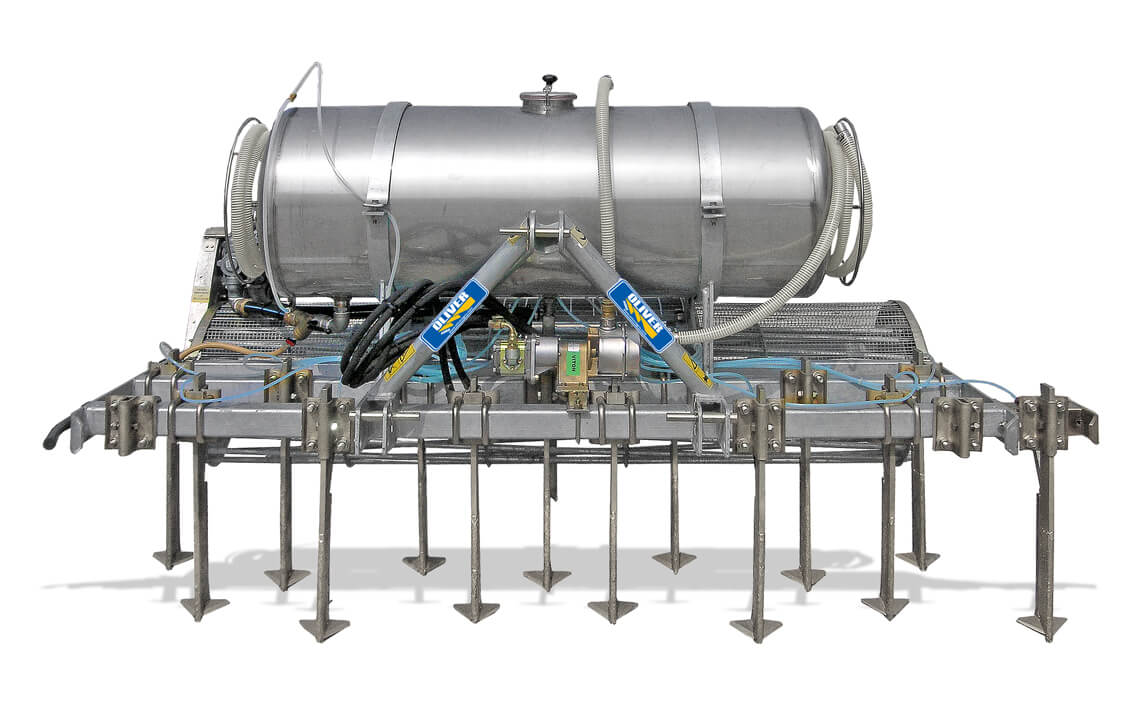

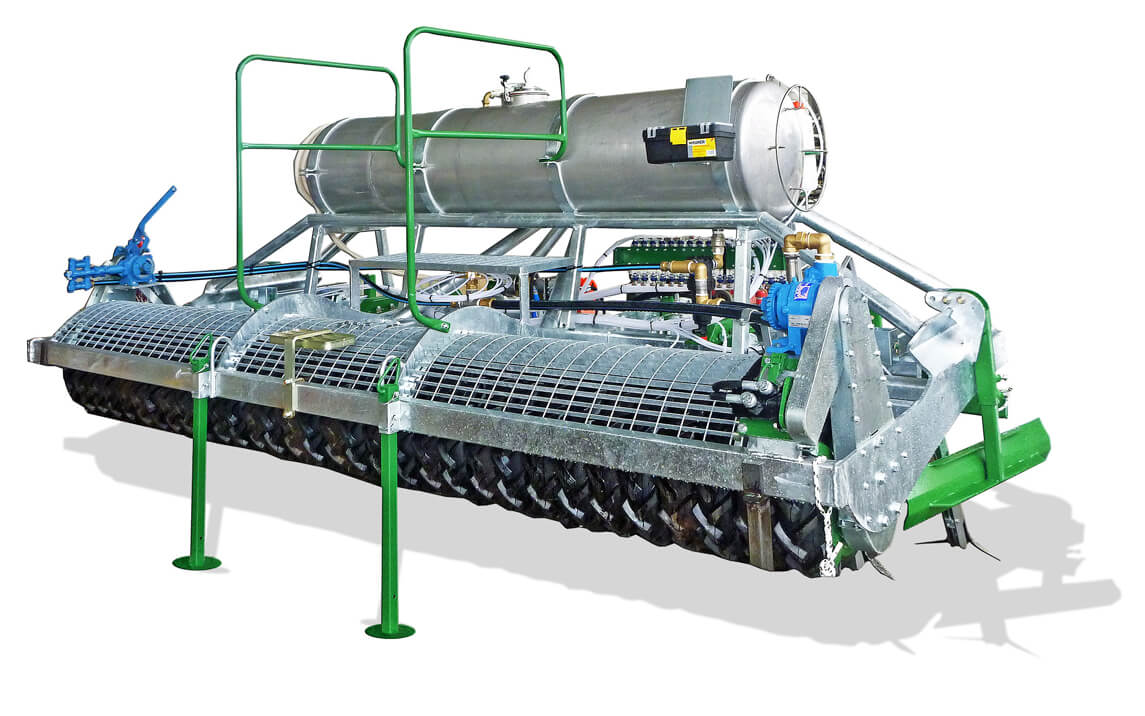

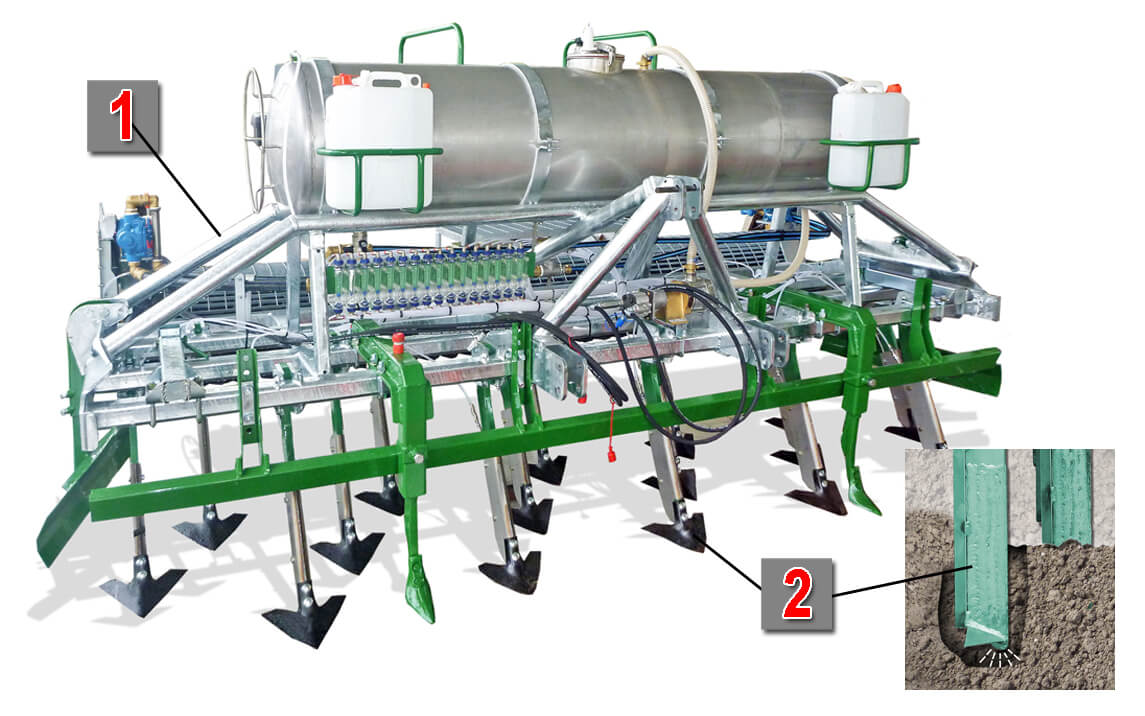

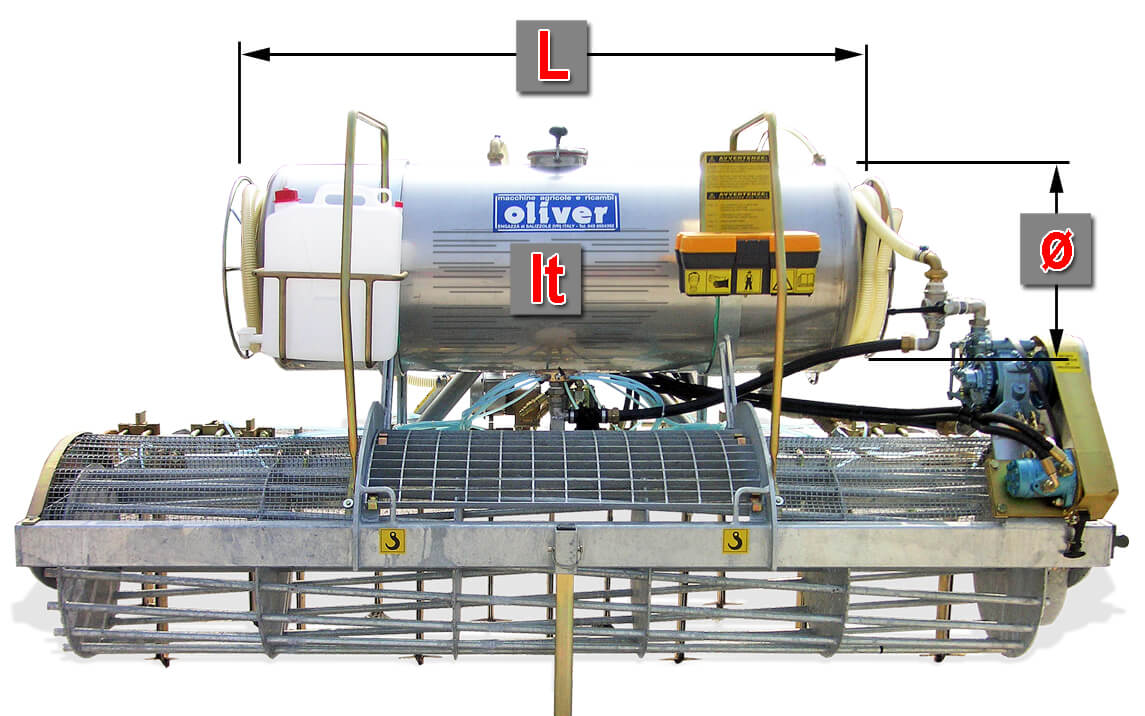

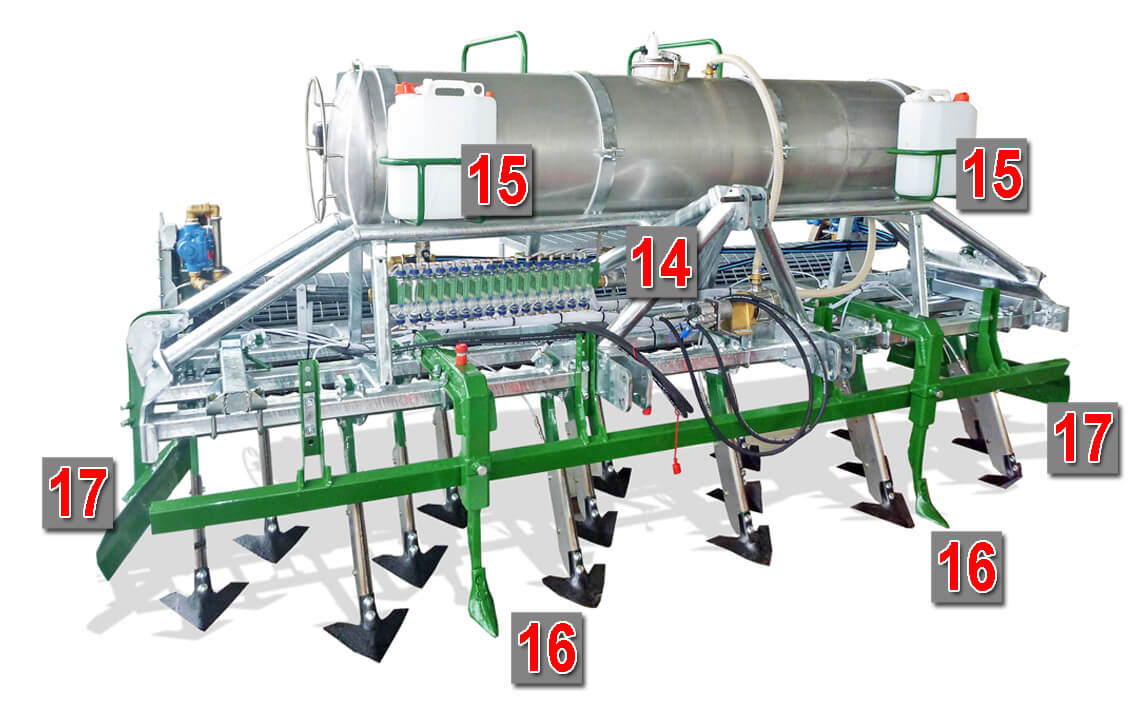

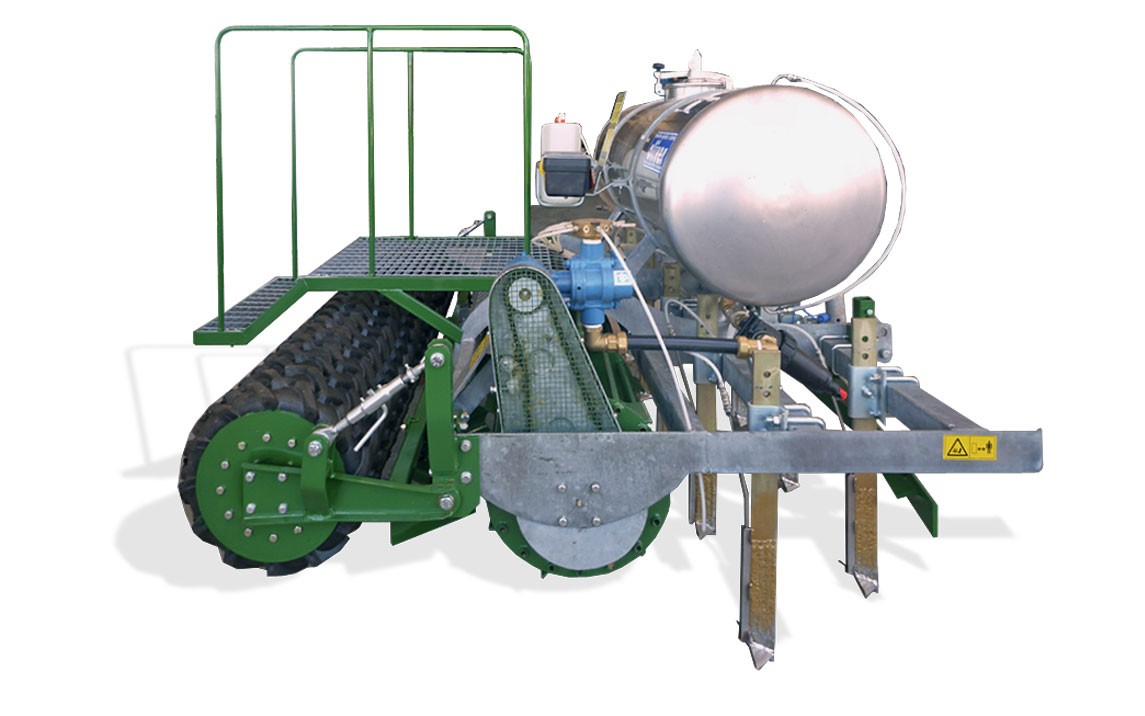

The Localizer Fumigant Machine LM it is a simple machine that performs soil sterilization with nematodes and fungicides.

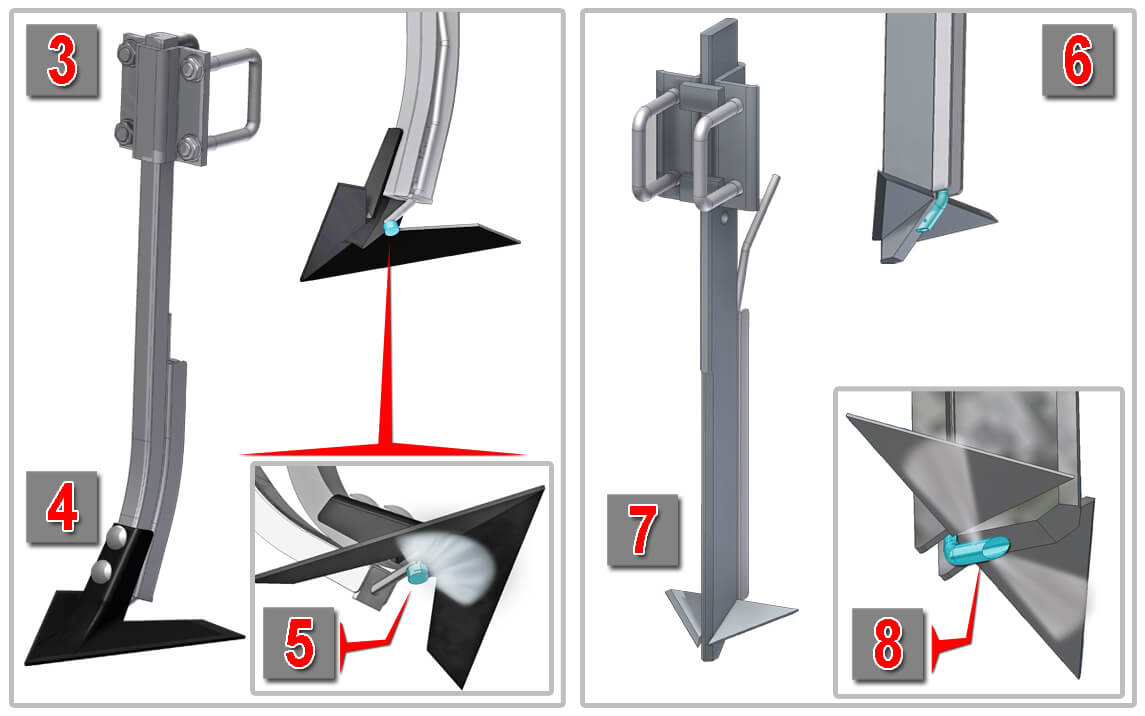

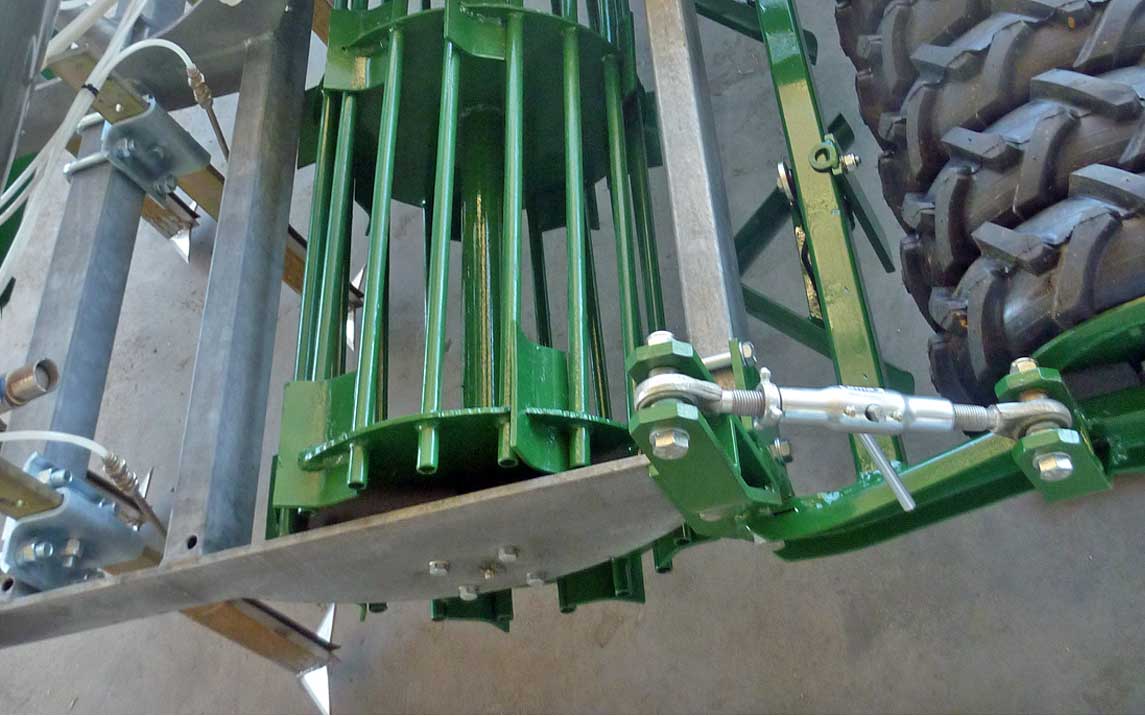

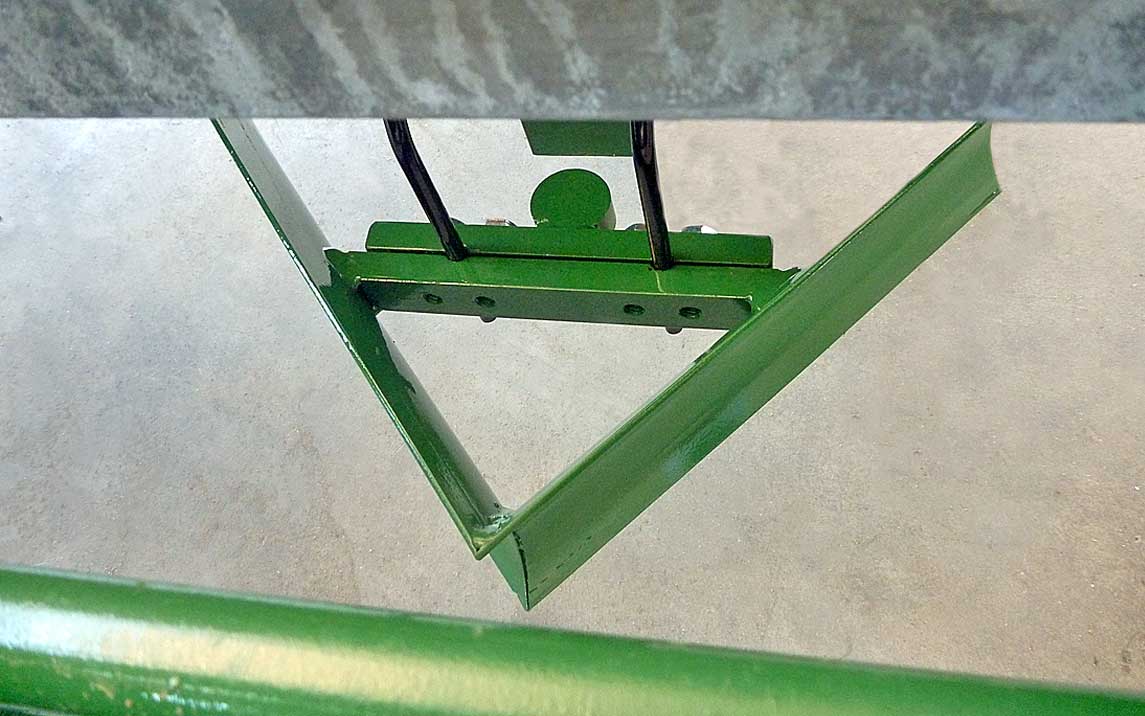

It adapts to any type of soil, thanks to the availability of two different models of locator knives.

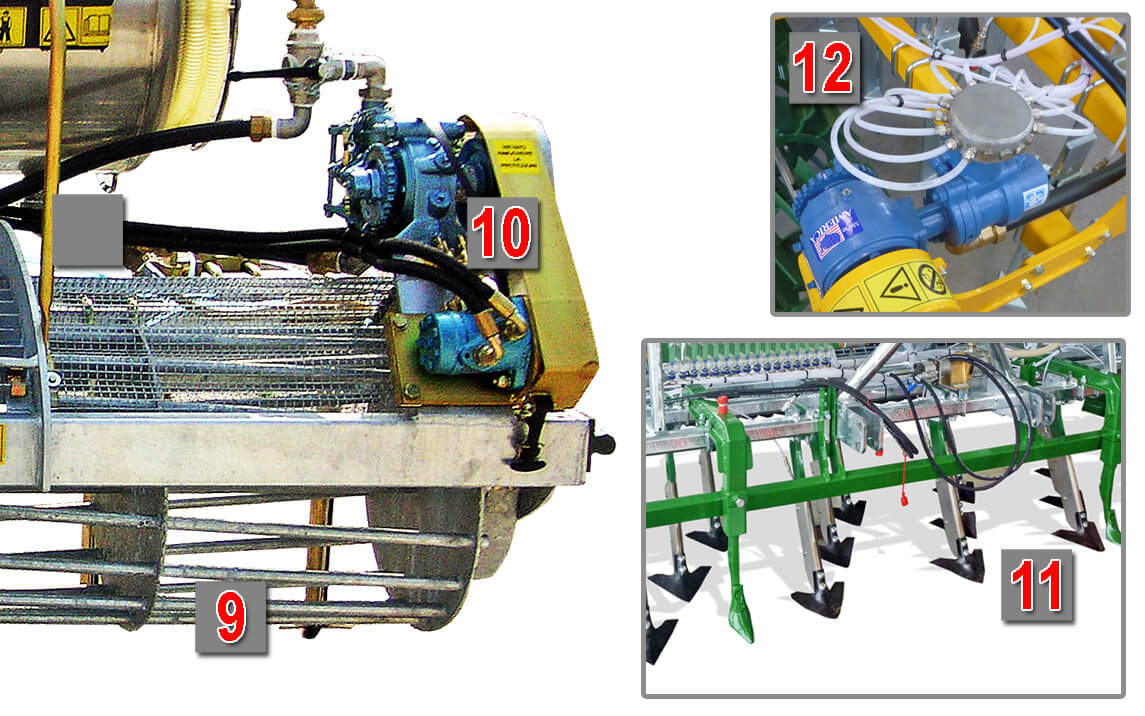

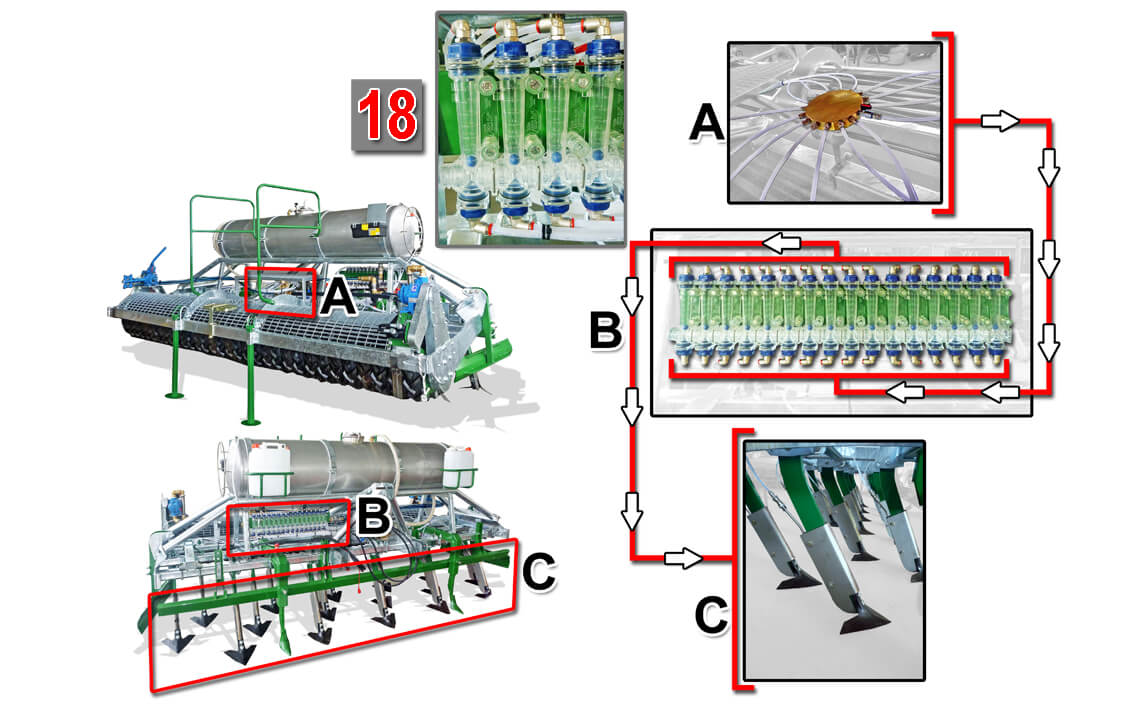

Thanks to a combination of innovative technical solutions:

-fumigation in depth

-compact, retaining the fumigant product in the subsoil