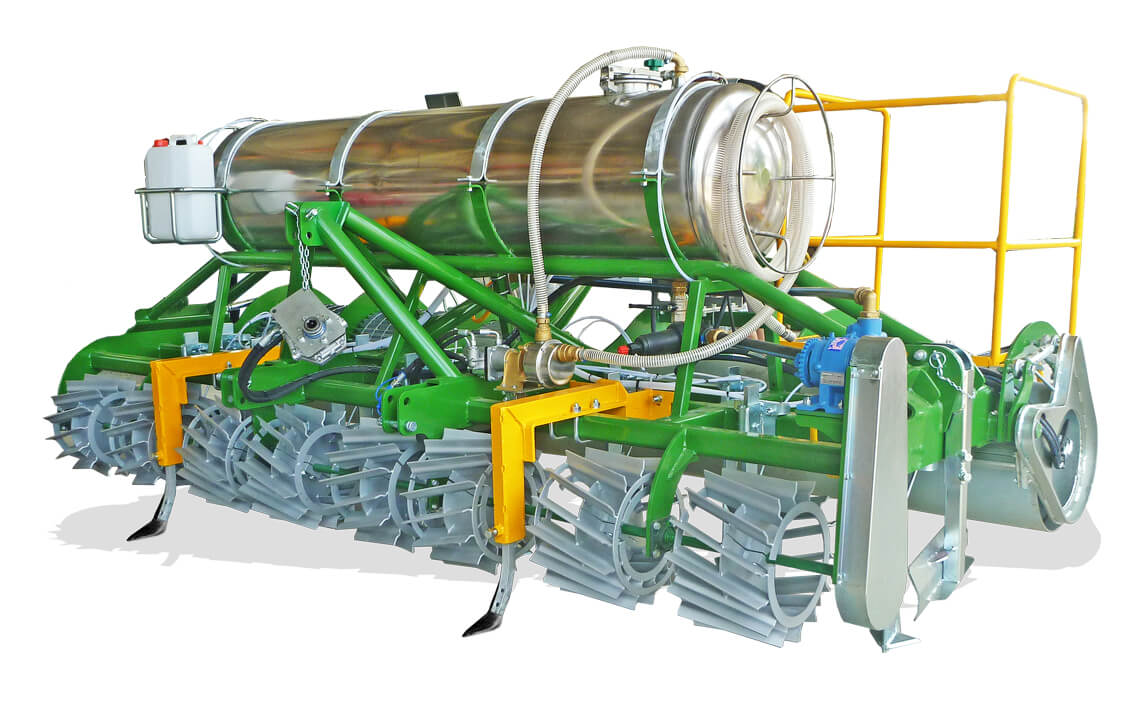

The New Velox Fumigator performs soil sterilization with nematodes and fungicides.

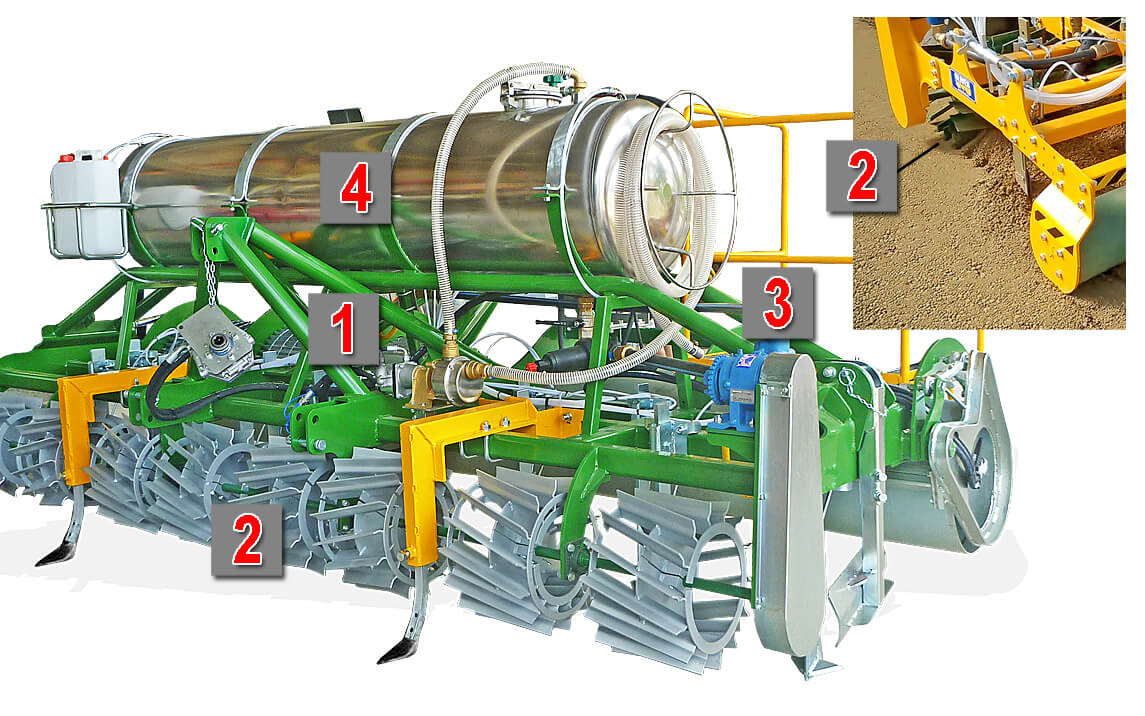

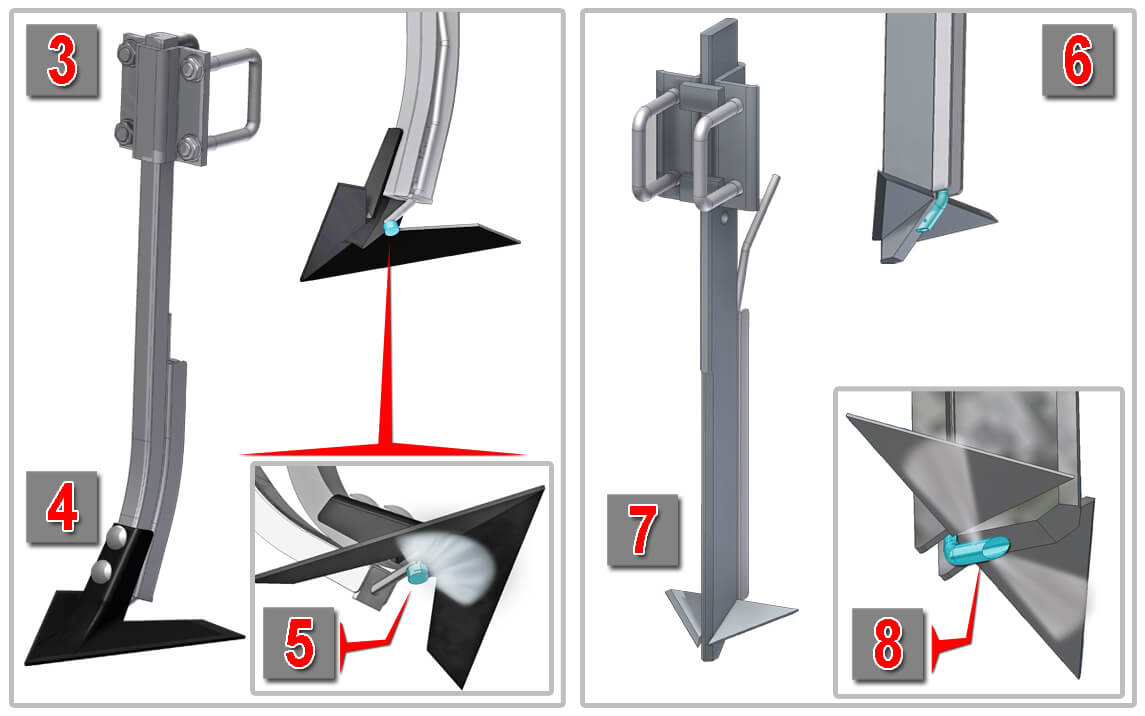

Thanks to a combination of innovative technical solutions:

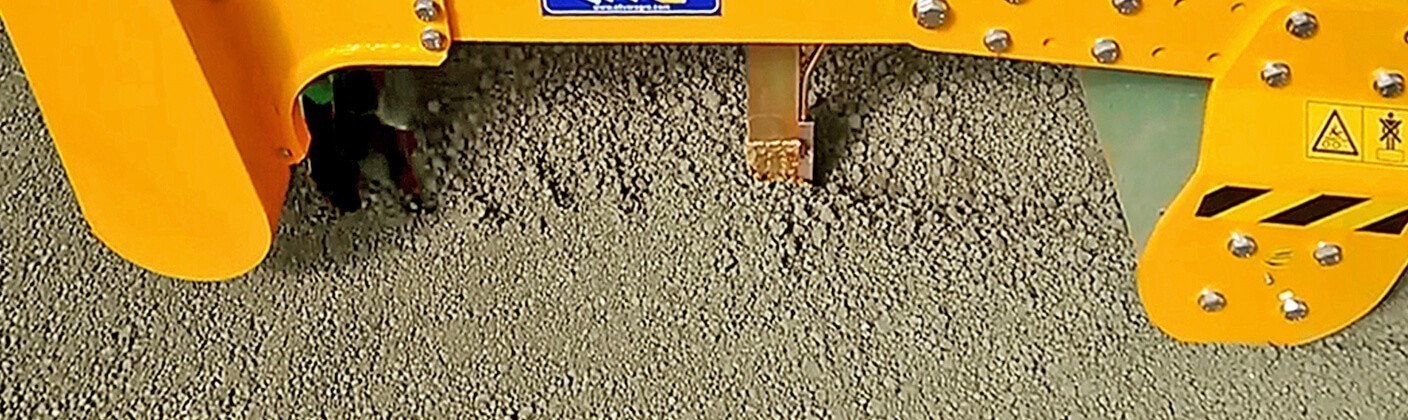

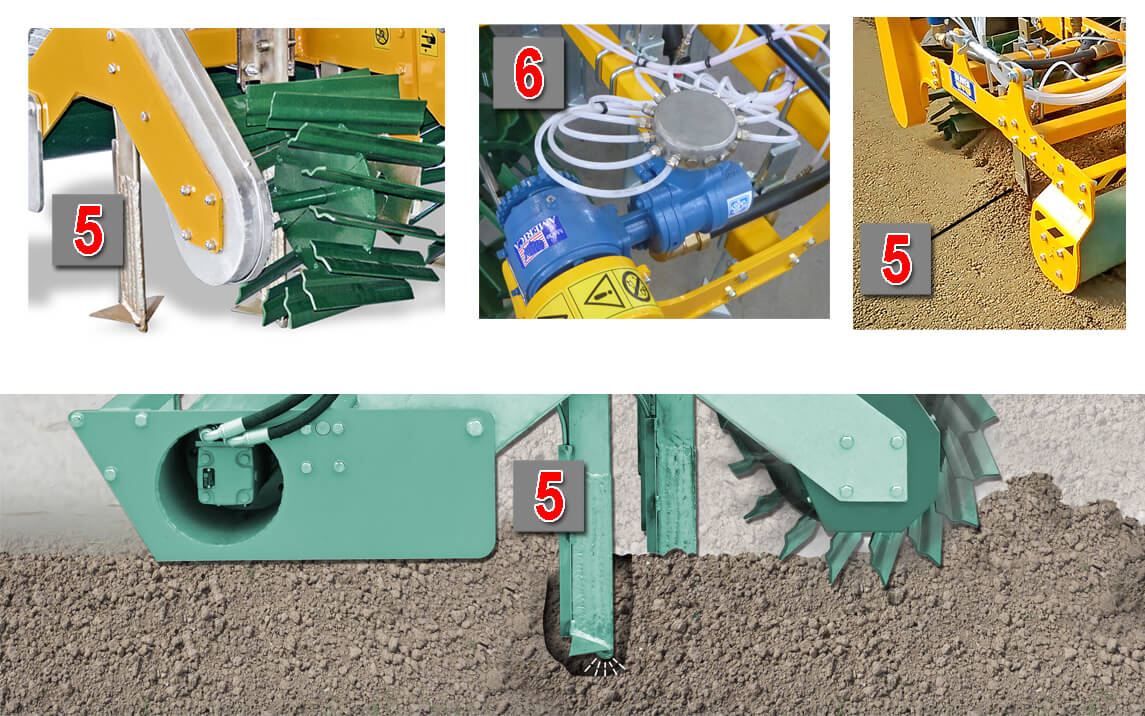

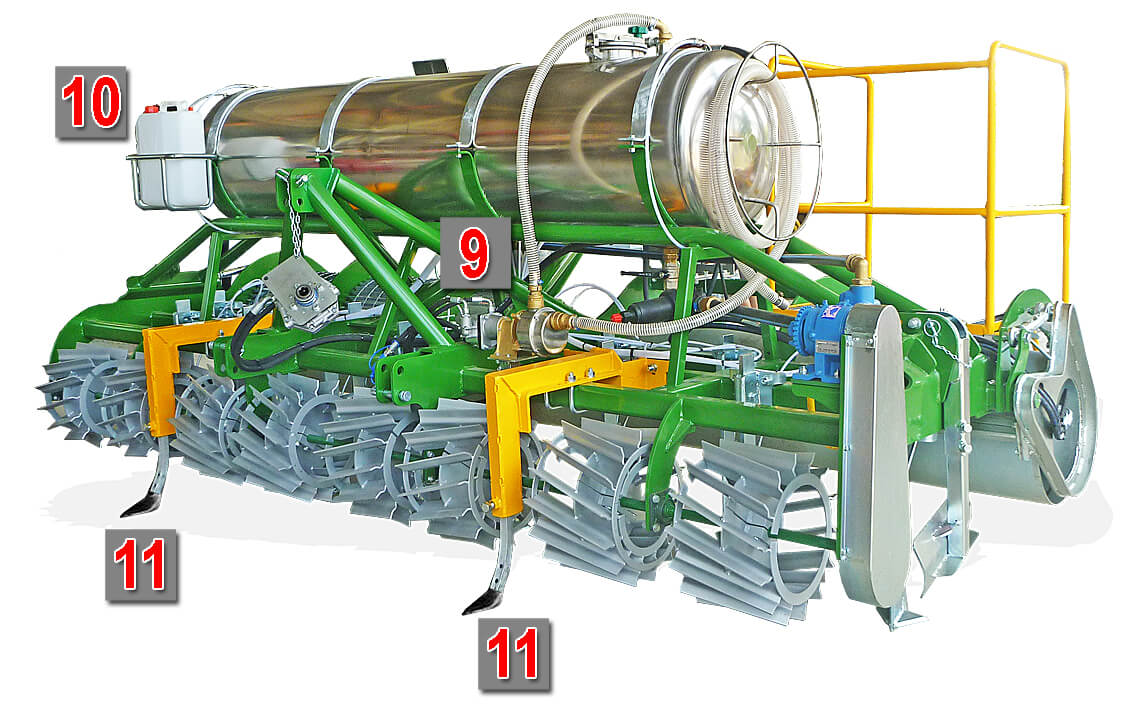

-prepare the ground

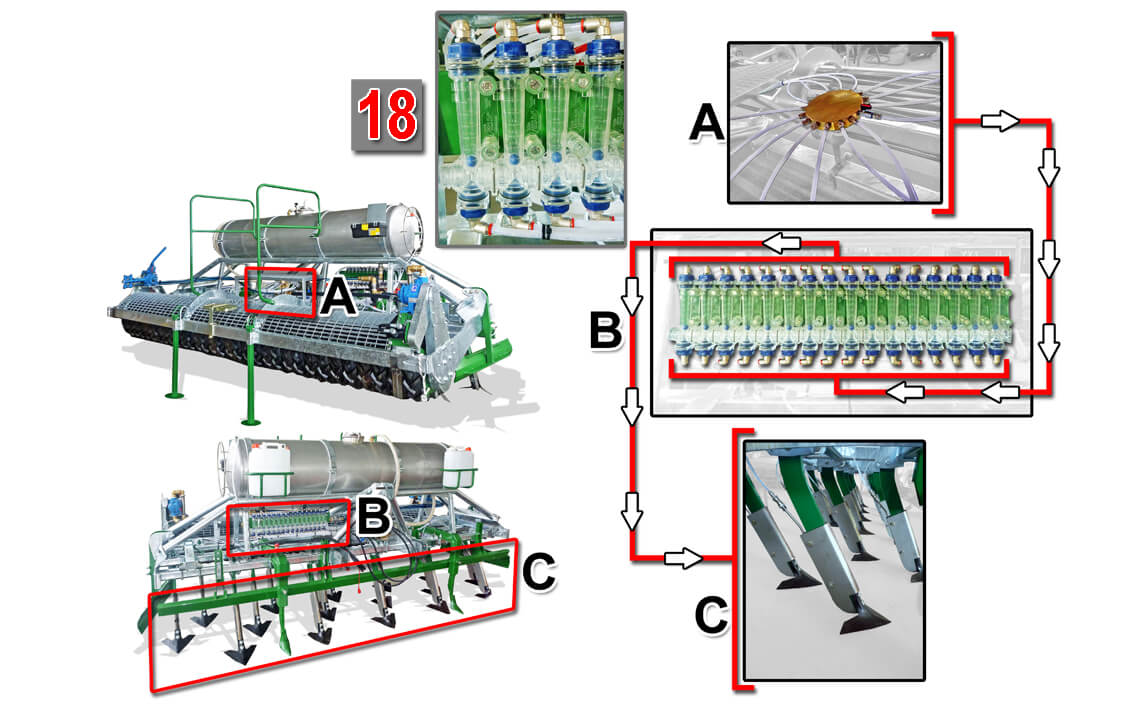

-sterilize in depth

-compact, retaining the fumigant product in the subsoil

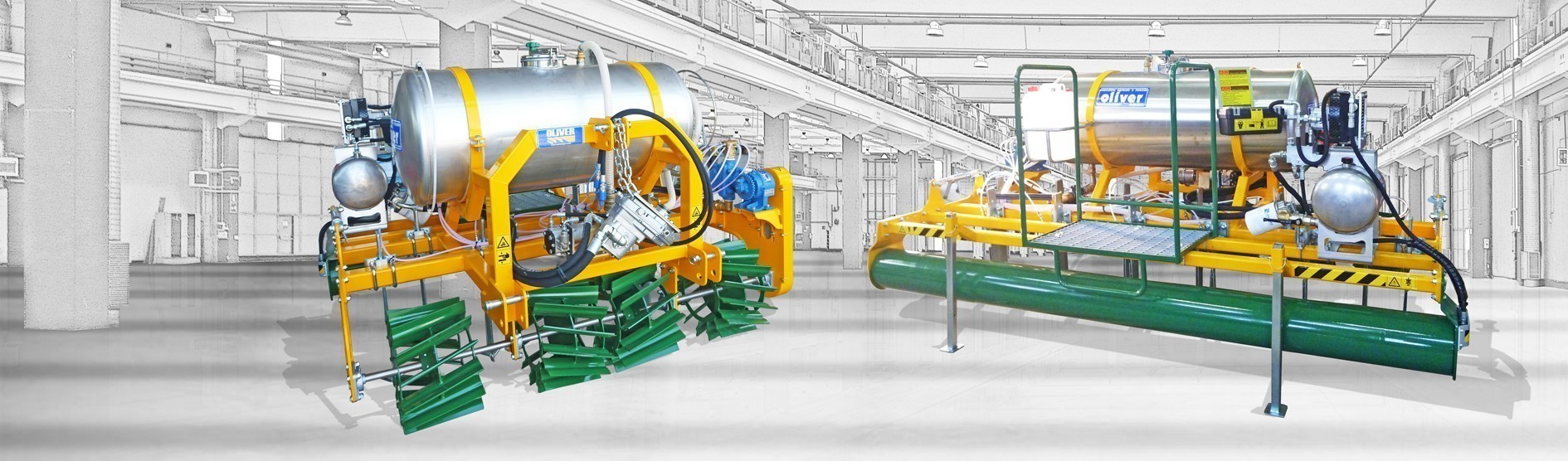

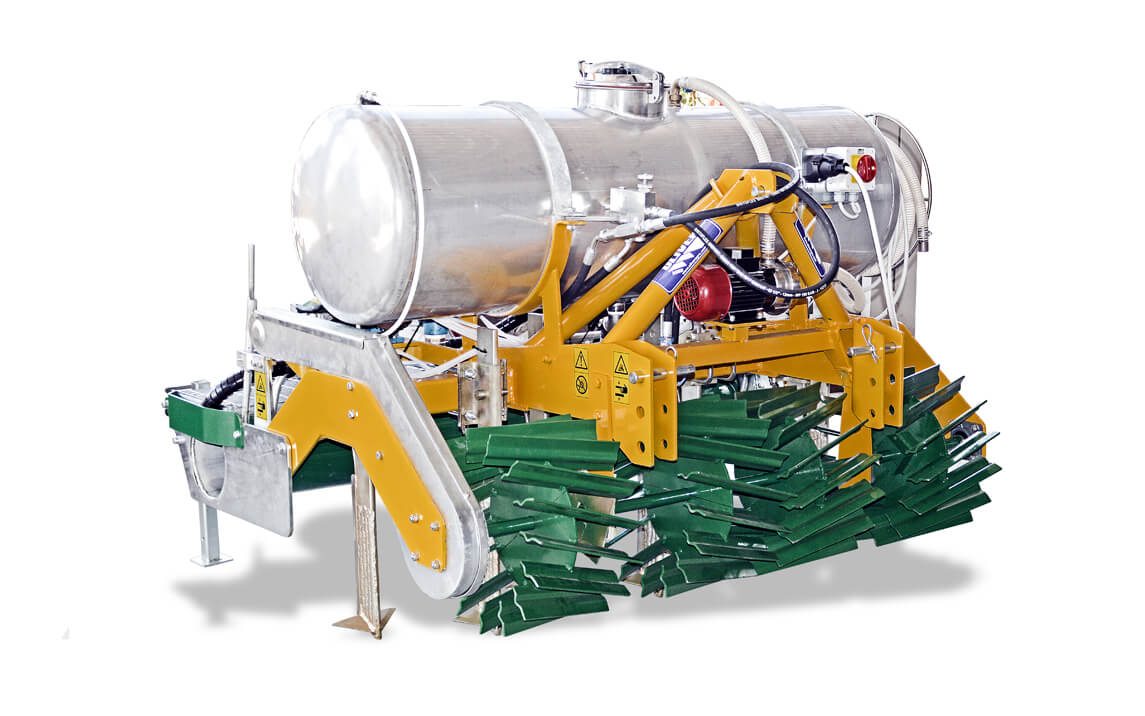

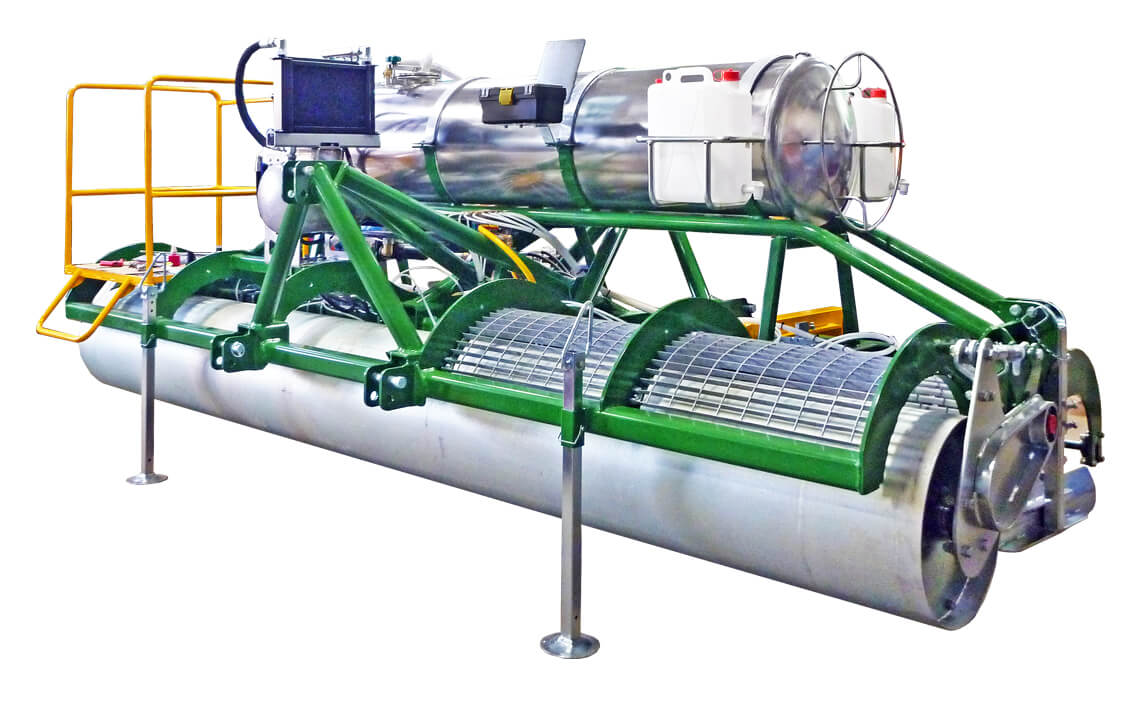

Expertly Manufactured Soil Fumigation Machine

Oliver Agro has been a respected name in the development of agricultural machinery for more than 40 years. Over that period of time, the company has developed a soil fumigation machine that helps to clean the soil from the weeds and for fungi or nematodes.

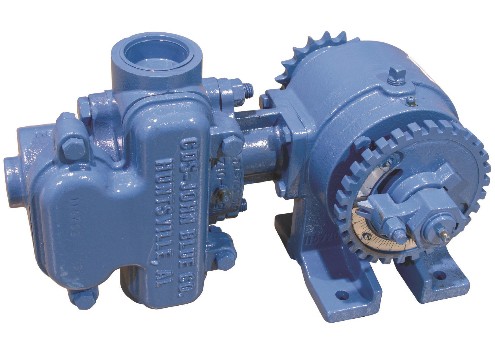

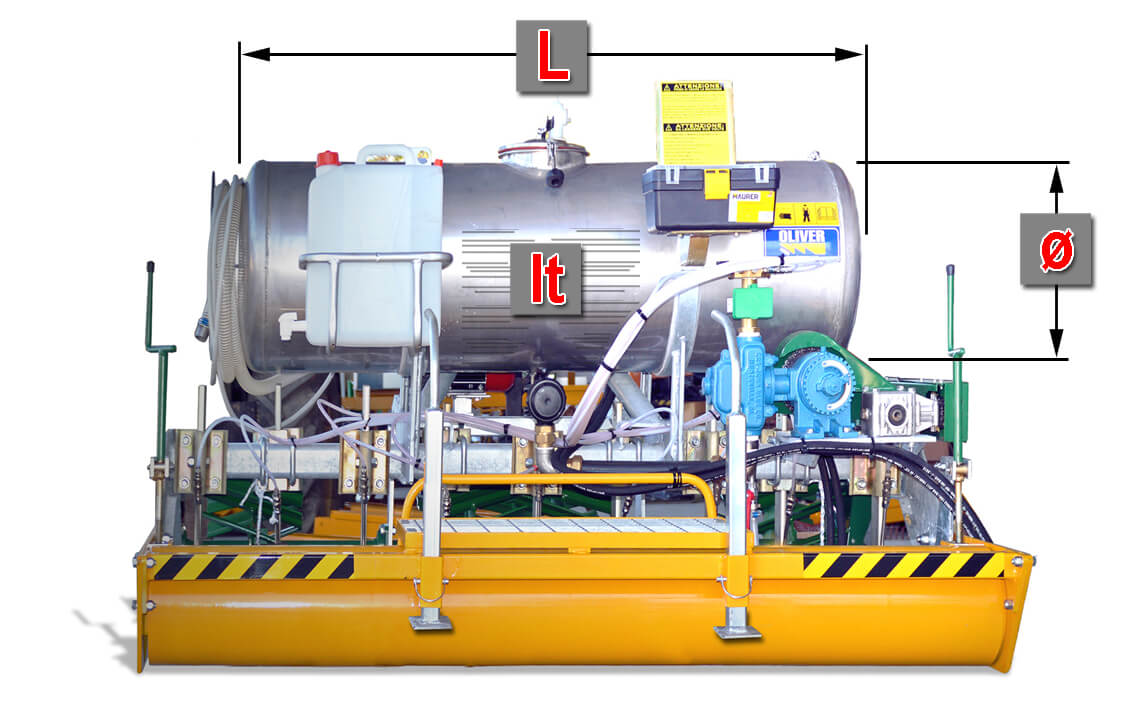

Choose a high performing soil fumigation machine

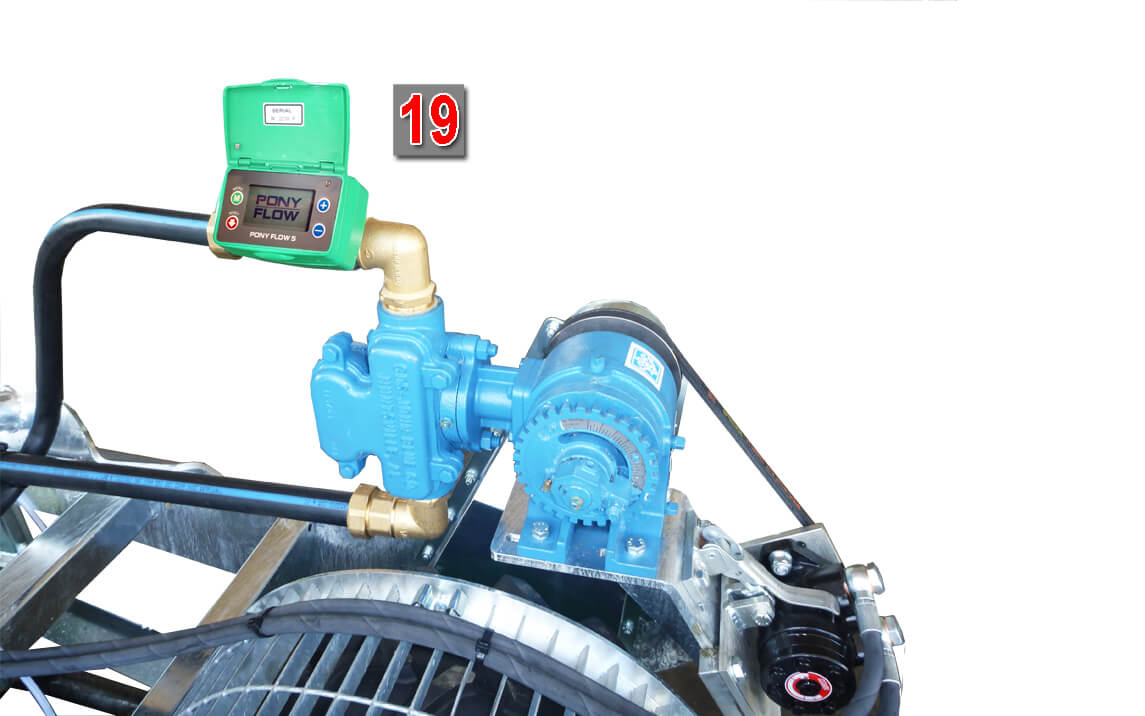

Fumigation is a specific need during soil preparation process. The new Velox Fumigator sterilizes soil from nematodes and fungicides or weeds, in other hand for granular application we indicate BASAMID/DAZOMET MIRROW localizer. This expertly developed soil fumigation machine helps to prepare the ground effectively, inject the production into the desired depth and enables fumigants to be retained in the subsoil. This means that the soil is well prepared prior to plantation. You get the benefits of highly developed technology in a soil fumigation machine that helps to ensure optimal soil preparation.

Get expert help with soil fumigation

You need to invest in a reliable and high-performing soil fumigation machine. Contact Oliver Agro to talk about all of your soil fumigation requirements and the expertly developed machinery that we provide. We are happy to answer any questions that you may have.