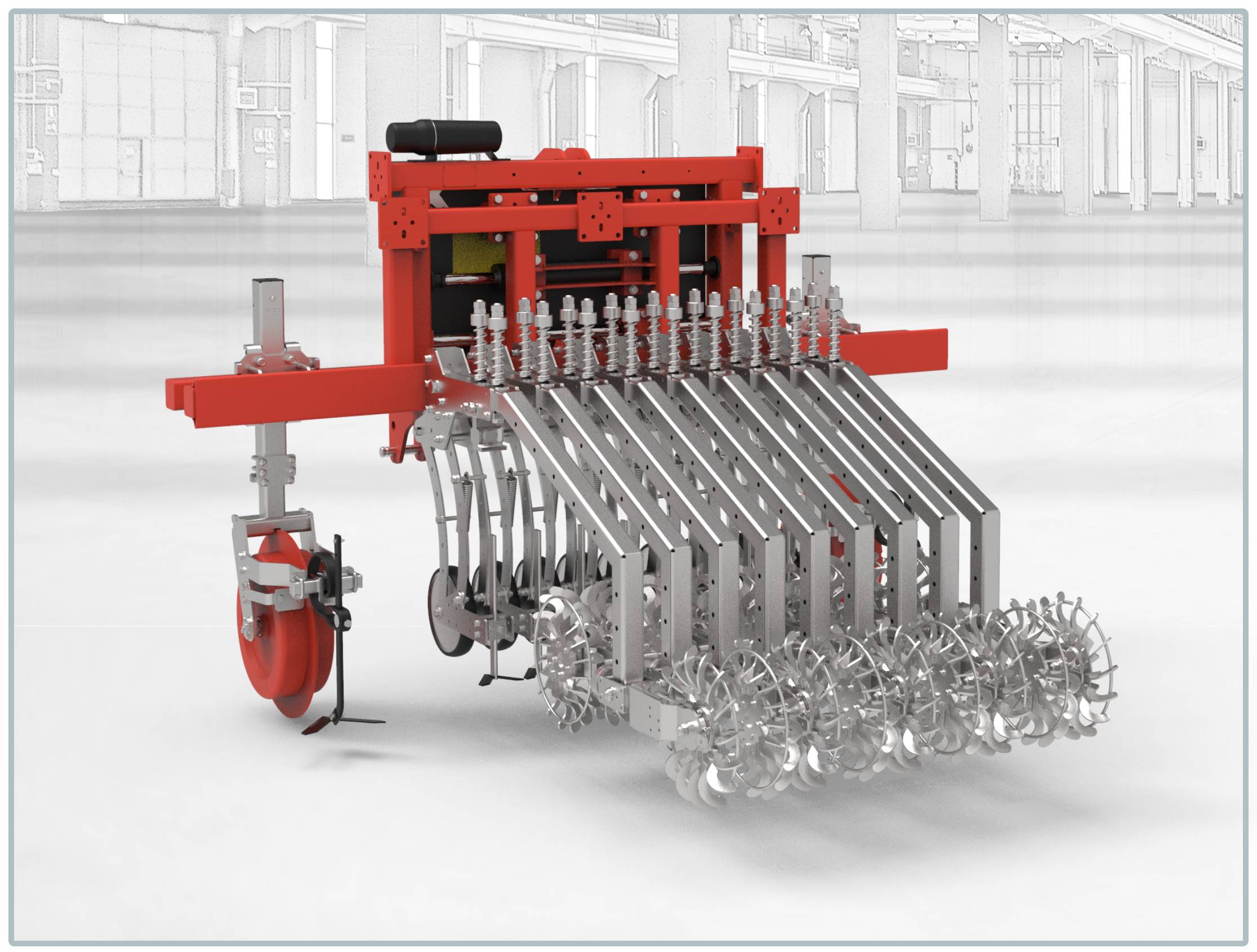

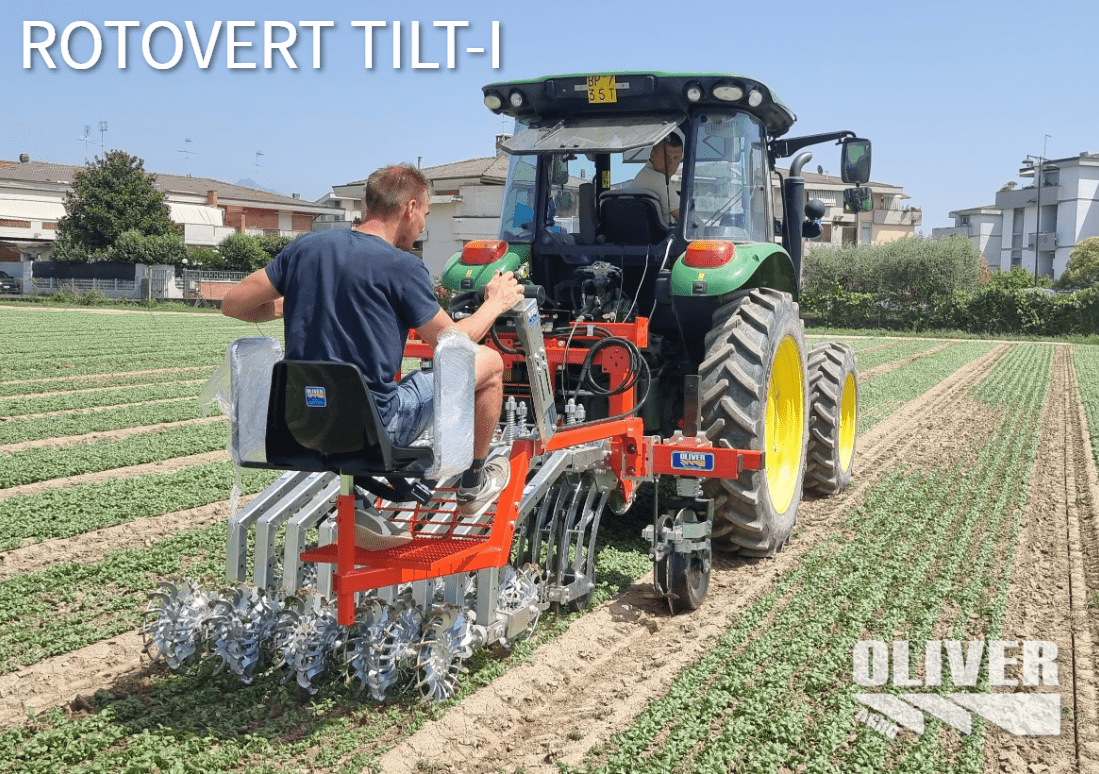

ROTOVERT TILT-I INTER-ROW WEEDER ON NARROW ROW SPACINGS

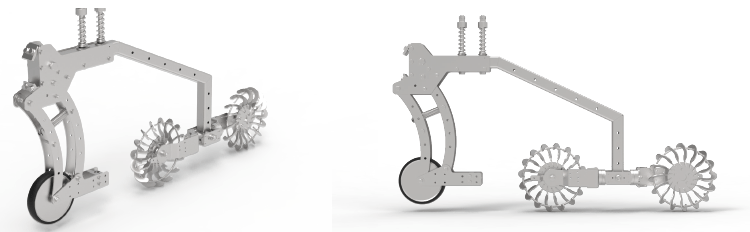

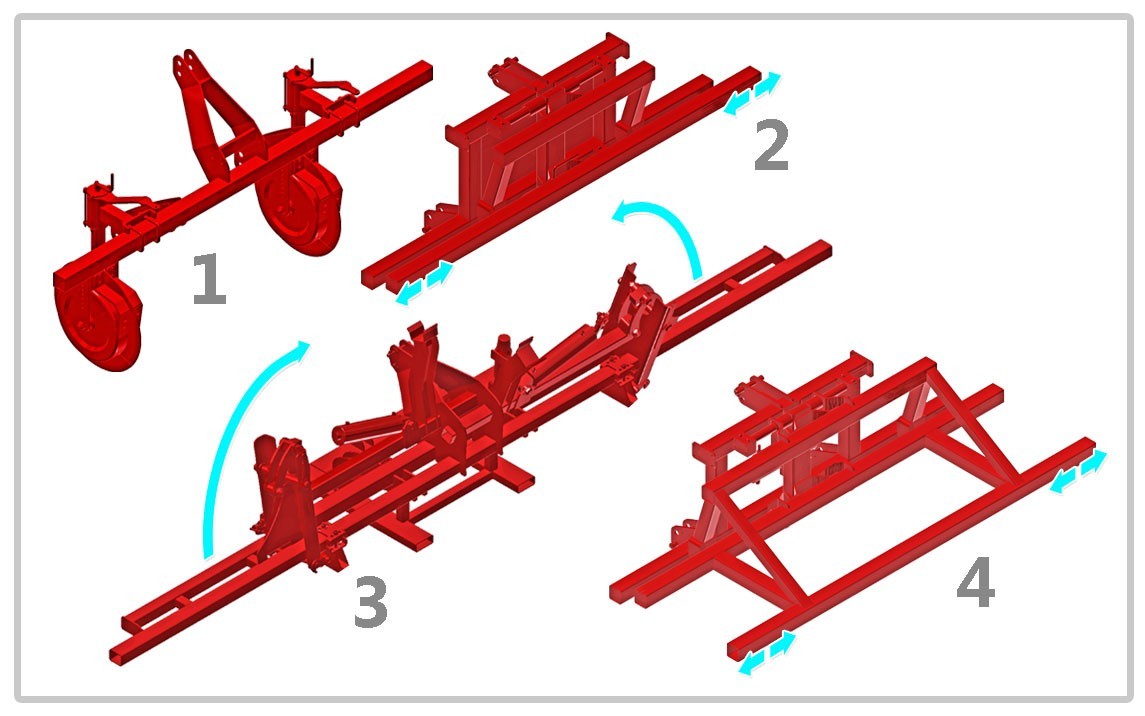

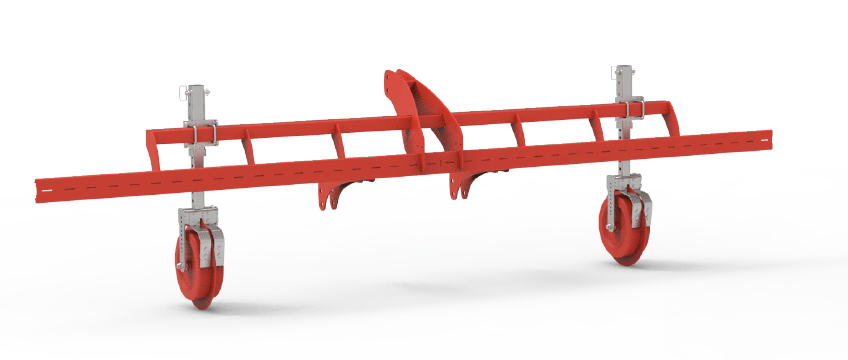

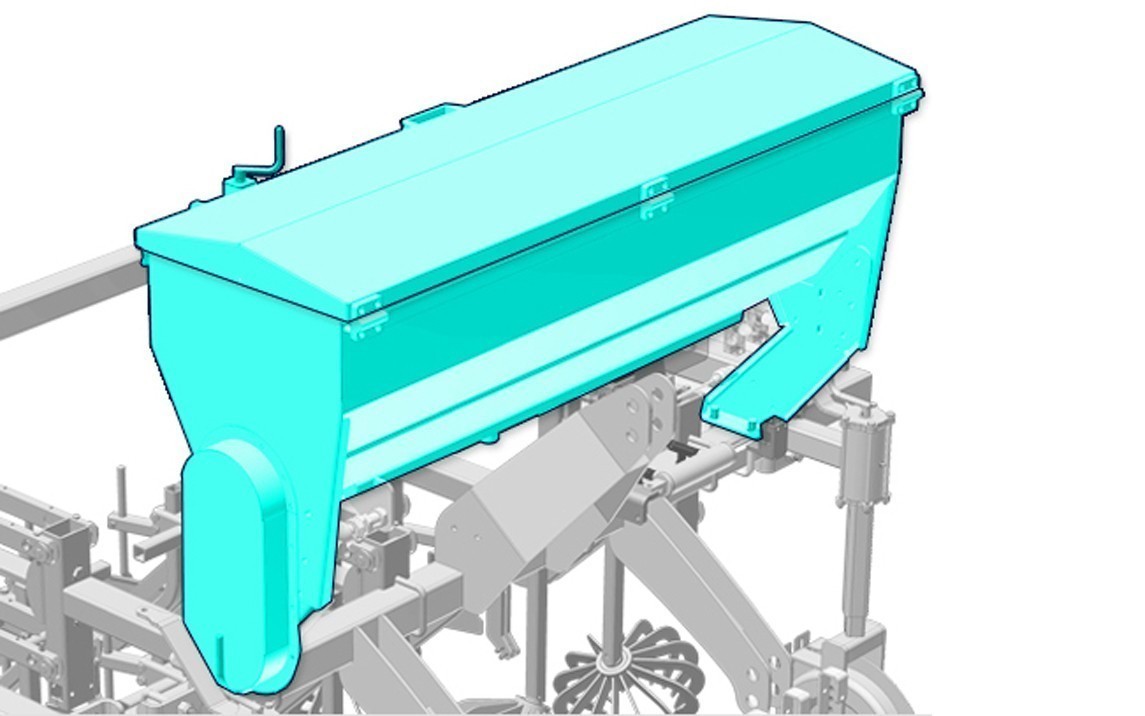

“Rotovert TILT-I” inter-row weeder with shifting frame; modular with parallelograms, variable load to working on the sown or transplanted row on very narrow inter-row distances from 13-25 cm.

![]()

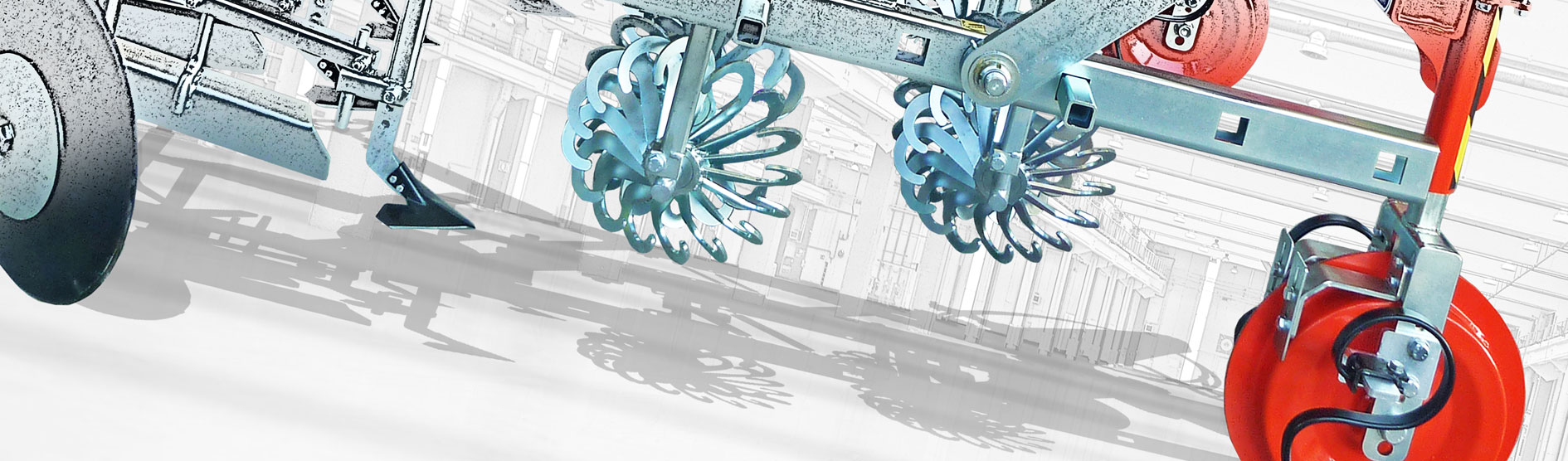

Rotovert acts directly on the transplant row without causing damage to the root and leaf system, eradicating weeds and thus reducing the need for chemical herbicides.

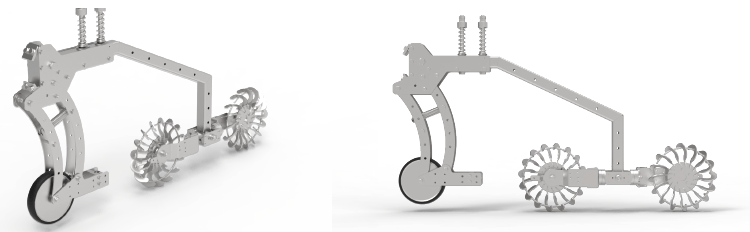

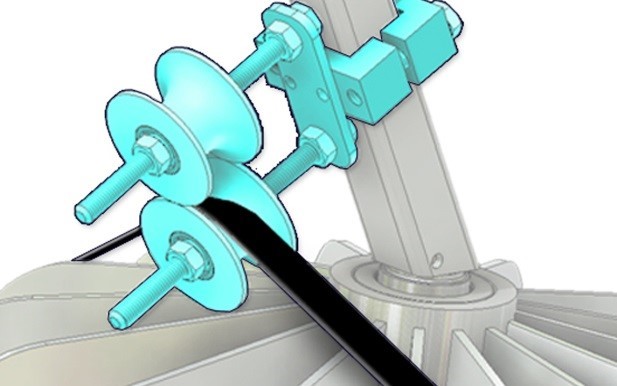

The Rotovert weeder and TILT-I parallelograms that carry the 2 rotors named precisely “Rotovert” (giving the name of the machine itself) that act directly on the transplant row without causing damage to the root and leaf apparatus, eradicating germinating weeds and thus reducing the need for chemical herbicides.

Weeding with Rotovert Rotors mounted on the TILT-I element is suitable for transplanted and seeded crops in line and on trunks (e.g., lettuce, onions, garlic, carrots, basil, spinach, flowers, arugula, and others), with inter-row spacing of 13 to 25 cm.

| TYPE OF SOIL | Sandy/medium texture and stony (with small stones: about 2-3 cm in diameter) |

| ROW SPACING | Minimum 12.5 – 6′ (inches) |

| INTER-PLANT DISTANCE | – |

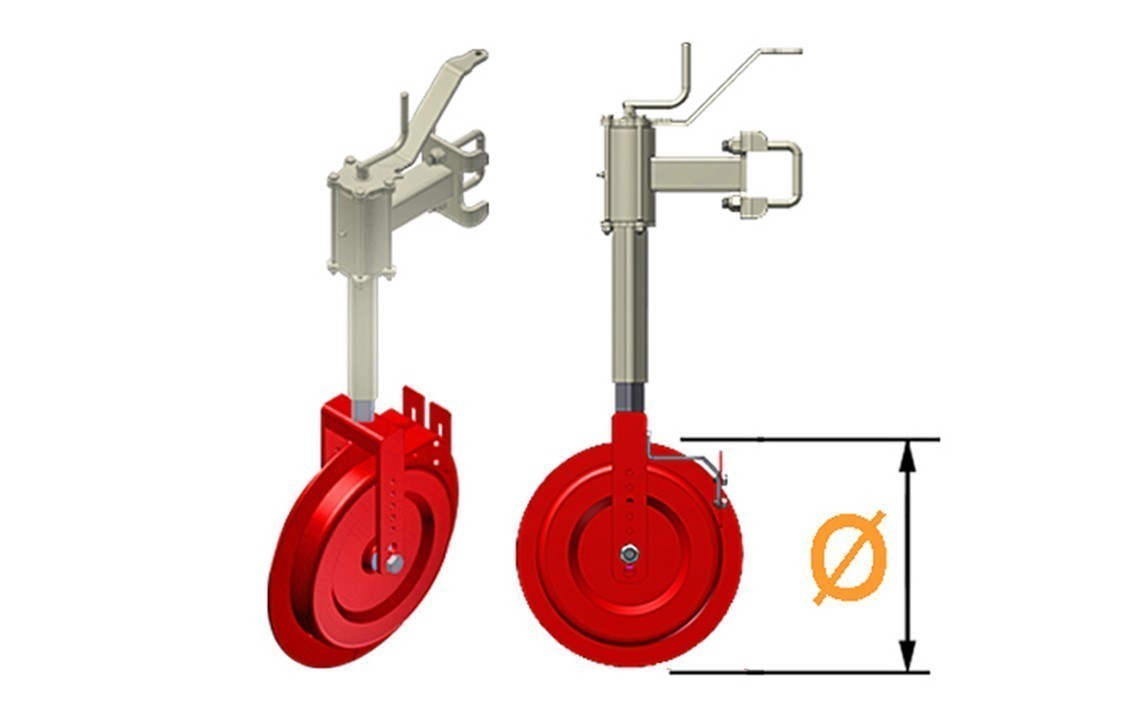

| ROTOR DIMENSIONS | A unique Rotovert model with adjustable tilt |

| WORKING SPEED | 2 – 5 Km/h |

| REQUIRED PREPARATION OF THE LAND | Good in the absence of crop residues |

| ROW N. | Depends on the transplanter/seeder in use, even on multiple ridges |

| SYSTEM TYPE | Mechanic |

| USE | Intuitive and modular |

TILT-T inter-row element with soil load variation by a spring, suitable for a machine that can be multi-trunk, folding.