ROTOFILM: THE WEEDING MACHINE FOR RIDGE or BEDS WITH PLASTIC MULCH

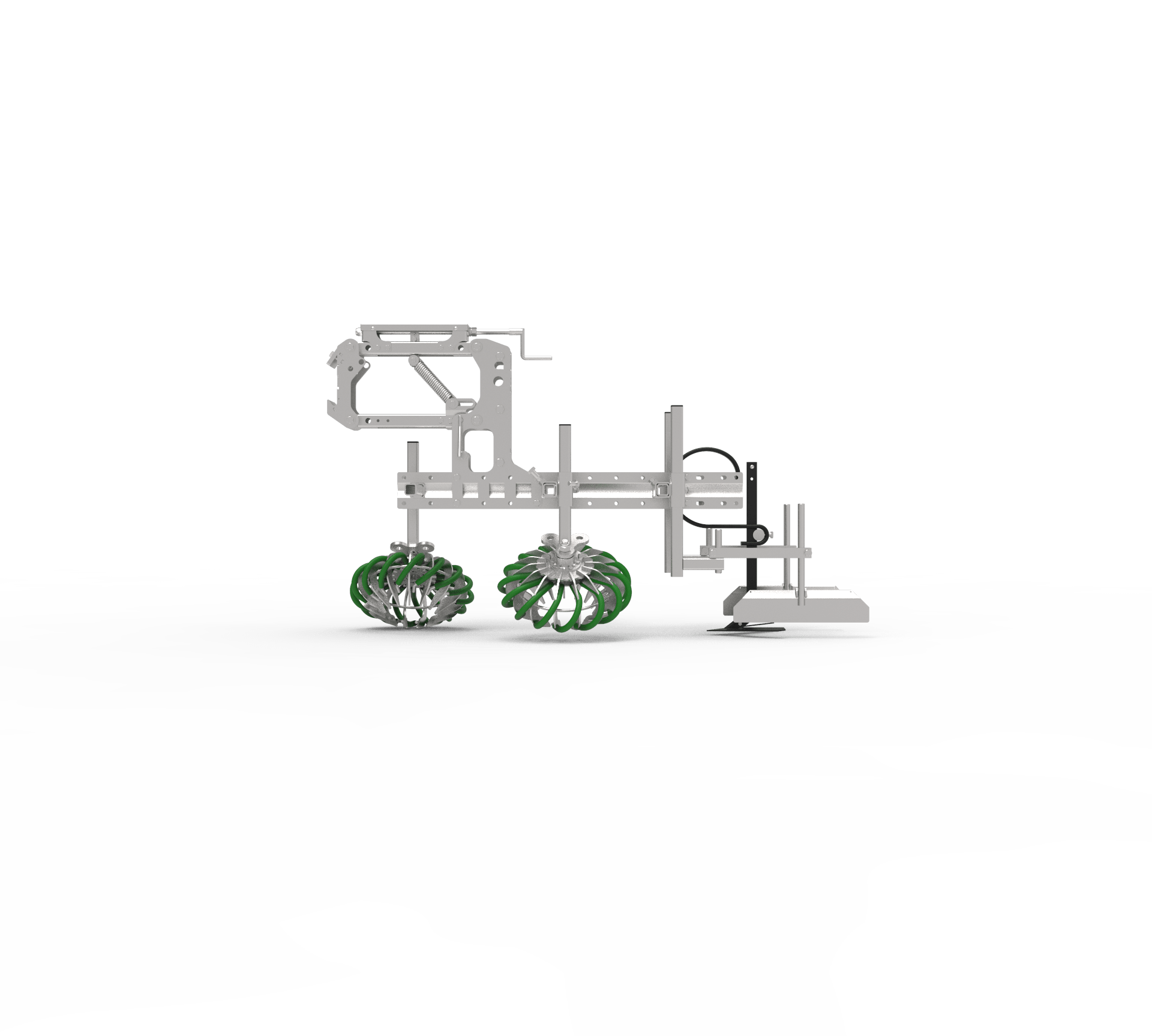

Rotofilm weeding machine with fixed frame or with hydraulic side shift with parallelograms working on the side of the bed or mulched ridge

![]()

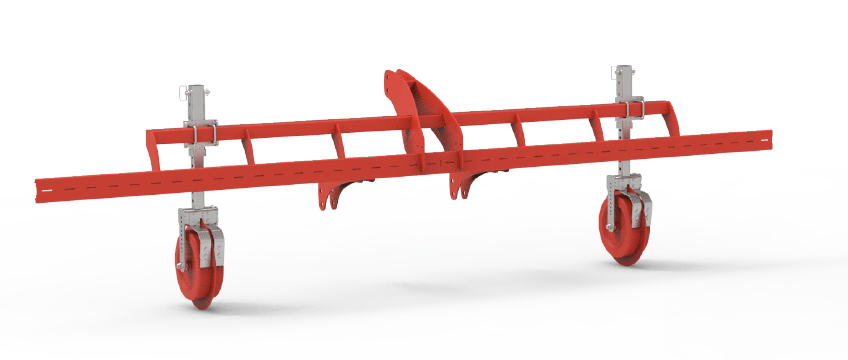

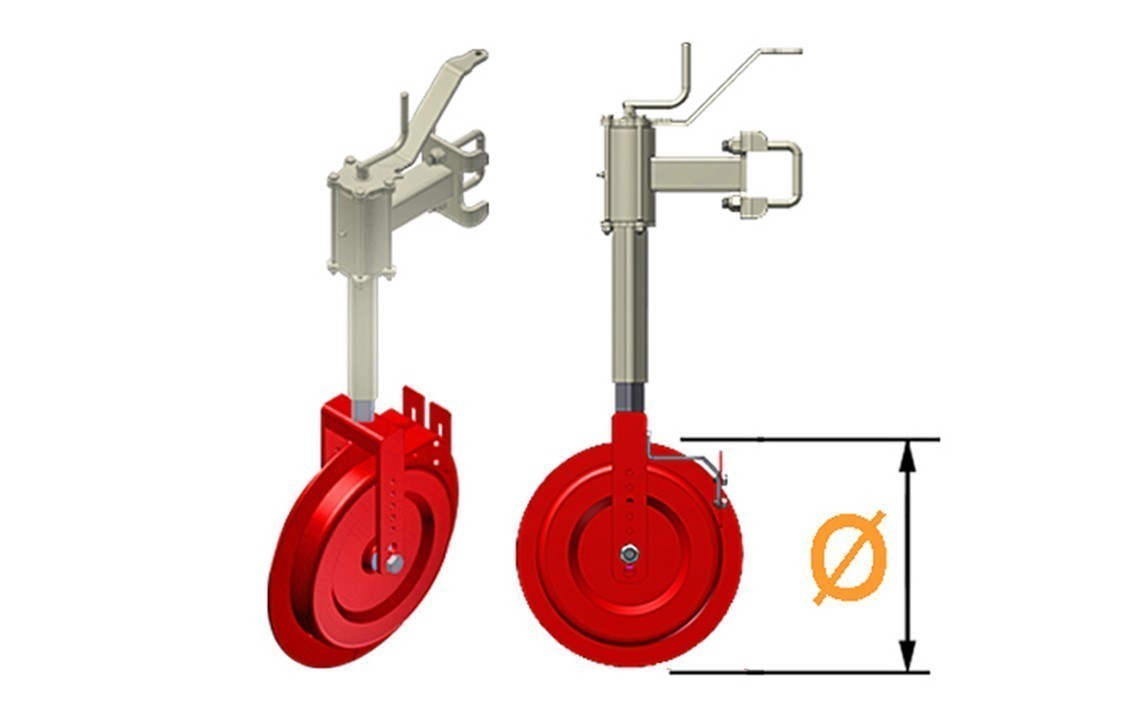

ROTOFILM WEEDING MACHINE is composed by a fixed frame 240 cm with 3-point hitch of the tractor with one or more ROTOFILM parallelograms with one pair of Rotofilm rotors Ø 350 mm with anti-intrusion rod per row, with 01 300 mm (standard) inter-row weeding soc per row and one pair of ridgers; 02 support wheels d. 320 mm with depth adjustment.

| TYPE OF SOIL | All |

| RIDGE DISTANCE | Minimum 70 cm |

| ROTORS DIMENSIONS | Fixed inclination 28° Rotoblizz Ø 35 cm with ROTOFILM Kit |

| WORKING SPEED | 4 – 7 Km/h |

| REQUIRED PREPARATION OF THE SOIL | With bed former/mulcher |

| N. of ROWS | on 1 or multiple beds/ridge |

| SYSTEM TYPE | Mechanical/Fixed machine |

| USE | Intuitive and modular |