The “COLIBRI” inter row weeding machine is used in fresh cut produce, baby leaf, fresh lettuce, arugula, little spinach, carrots, onions, basil and sown crops.

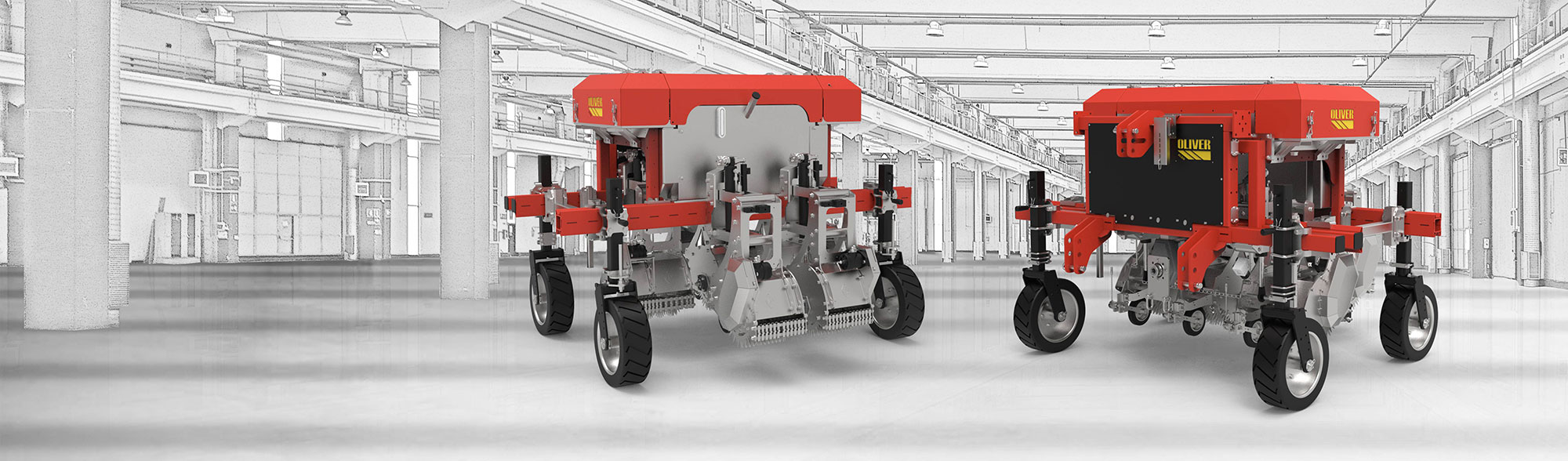

The COLIBRI weeding machine consists of:

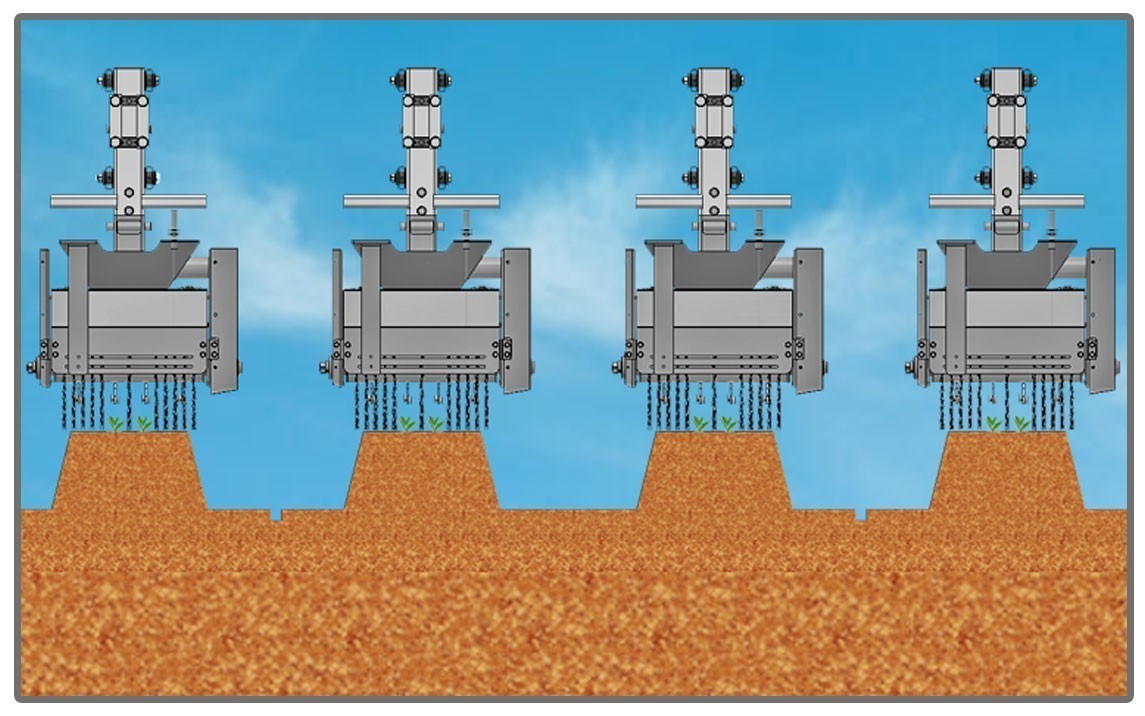

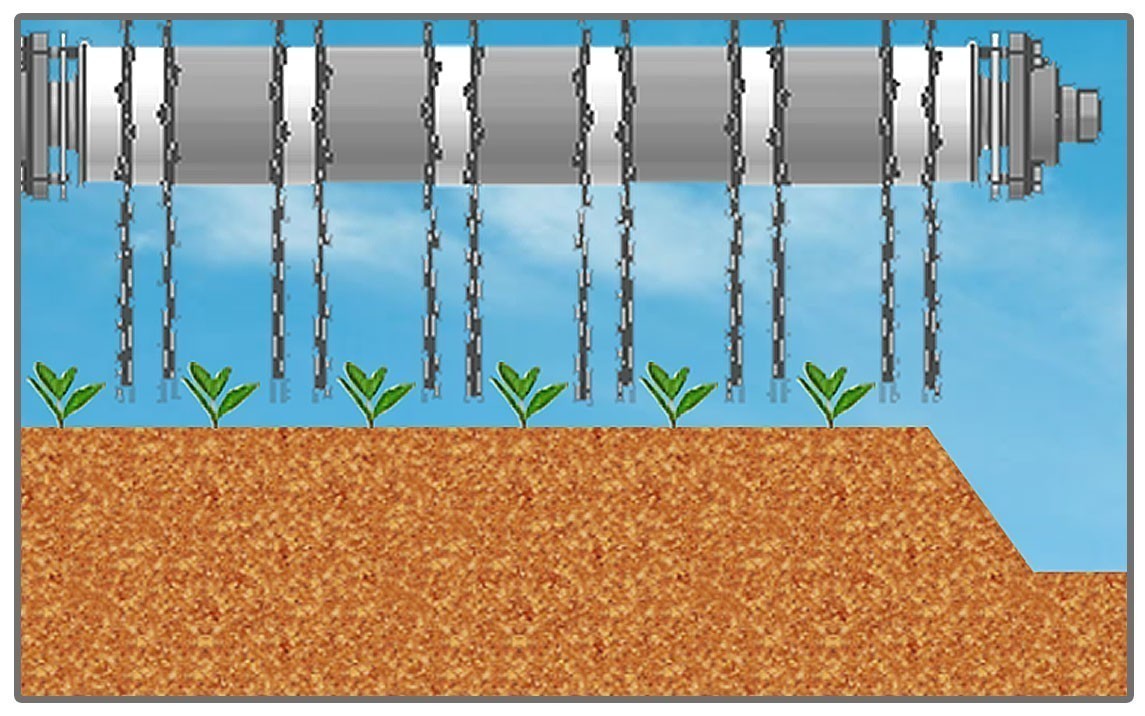

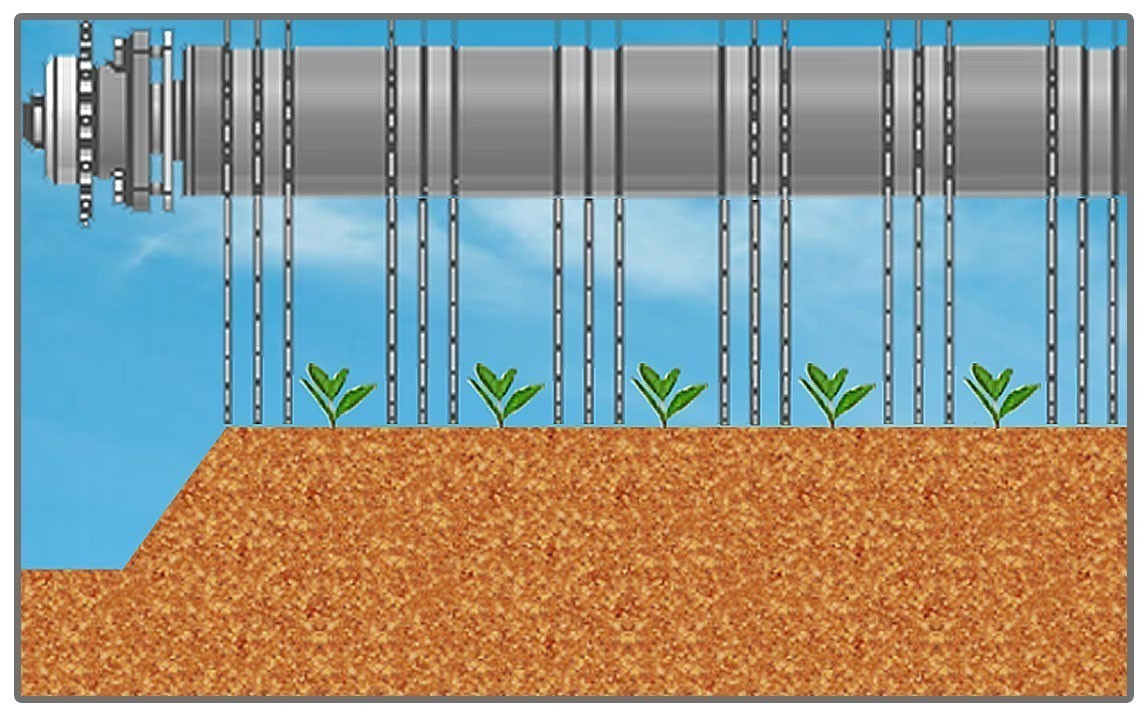

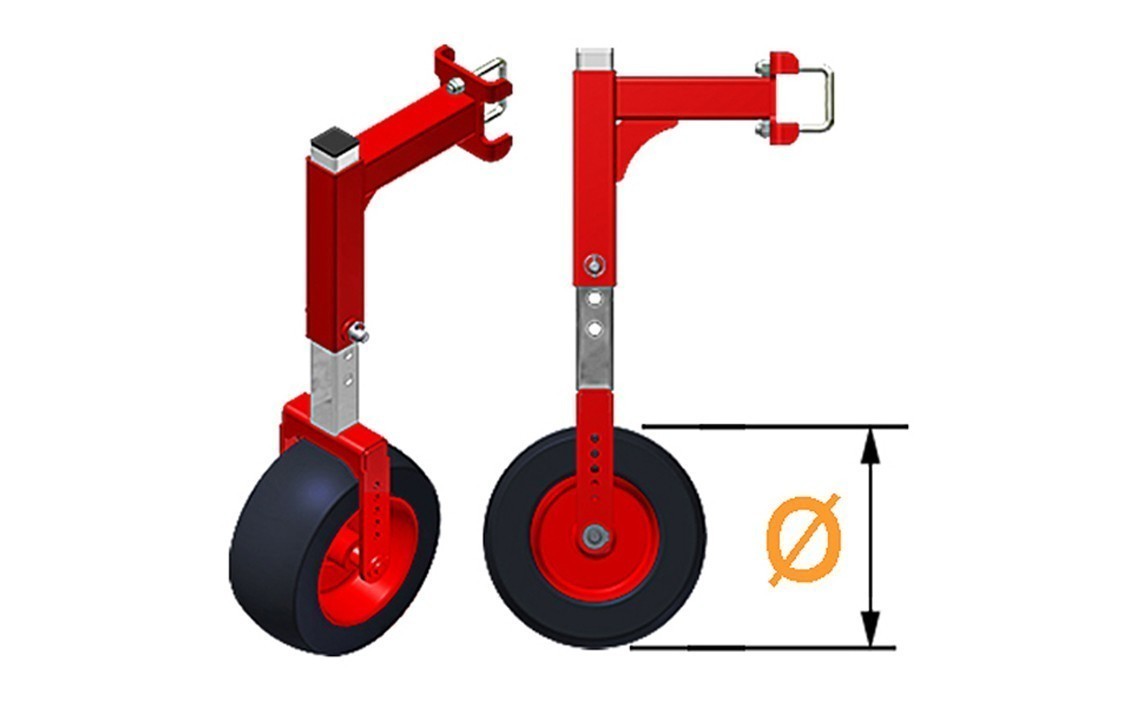

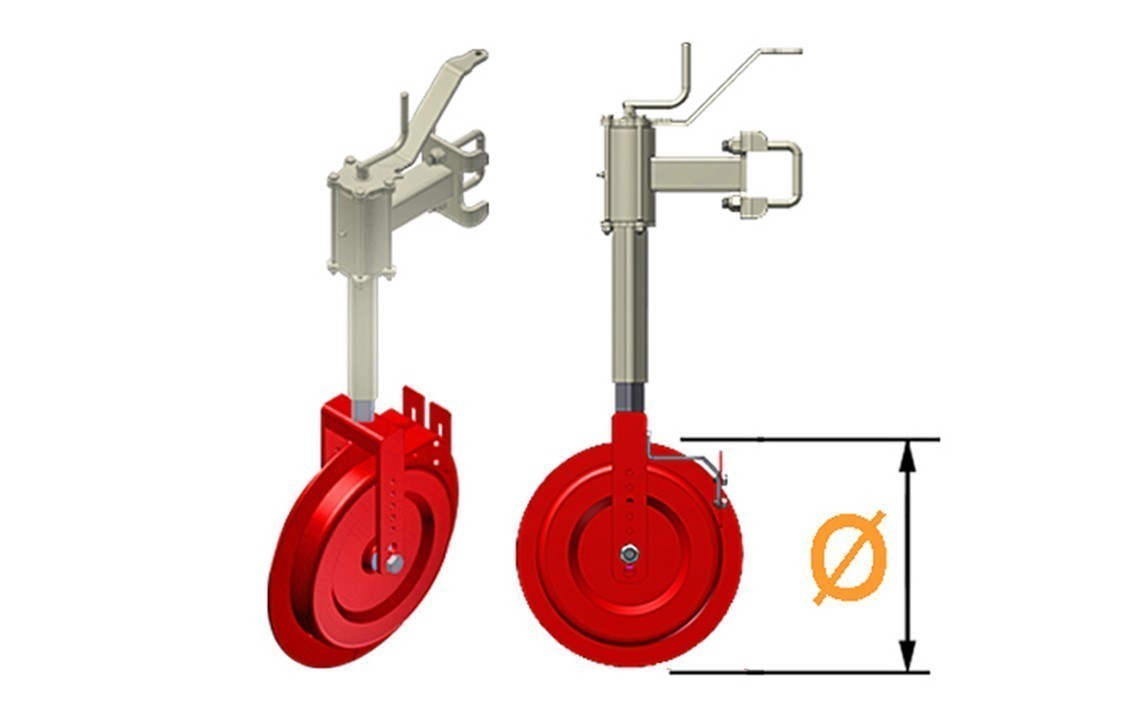

– A hydraulic three-point frame with a square shape, equipped with 02/04 grooved or pneumatic wheels to provide greater stability and avoid stress.

– An independent hydraulic system or hydraulic system connected to the tractor’s hydraulic outlets, with a reliable oil flow.

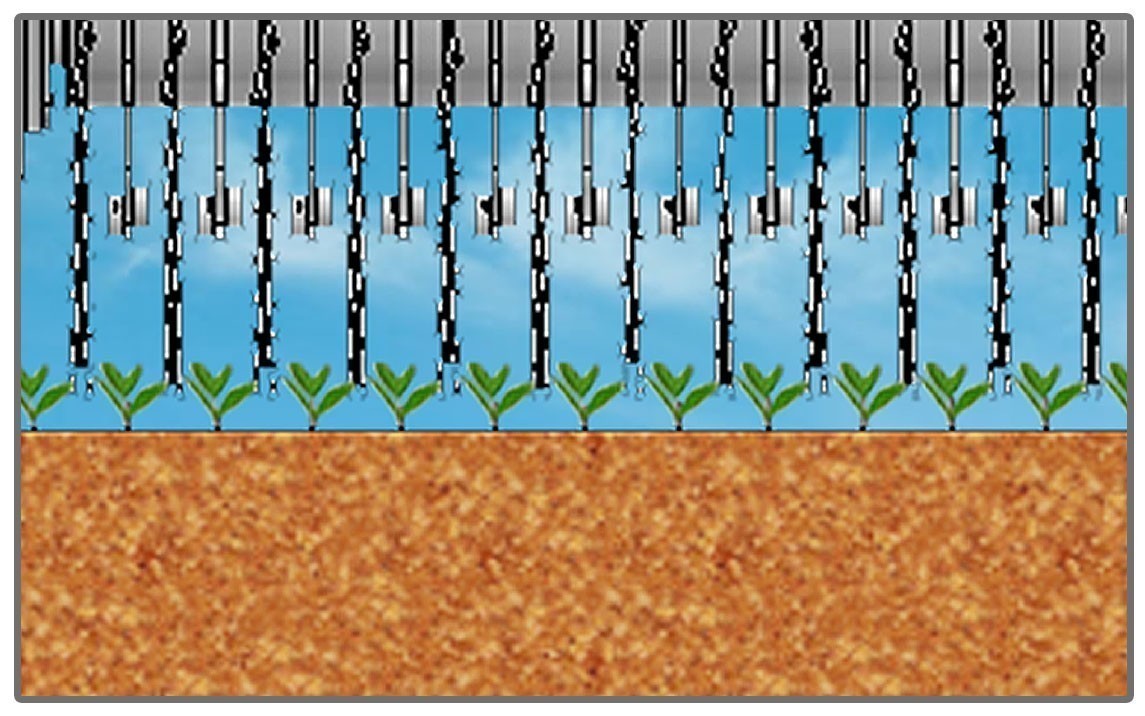

– A series of hydraulic parallelograms with toothed steel weeding discs, configured according to the specific sowing.

– Travel speeds range from 0.5 km/h on baby leaf crops ( we reached 2 km/h in open field at 5 cm), 0.8 km/h on aromatic herbs, and up to 2.5 km/h on carrots.

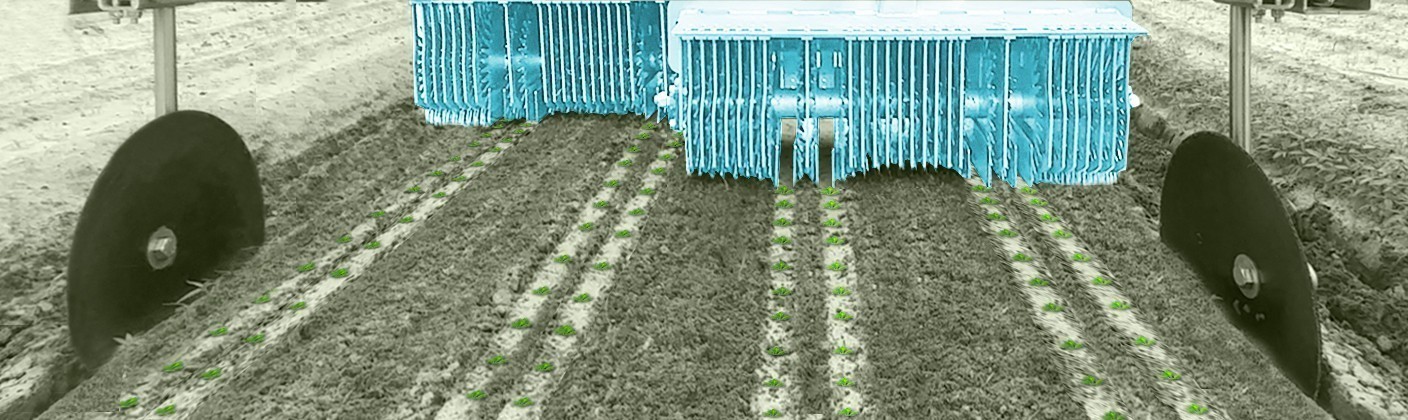

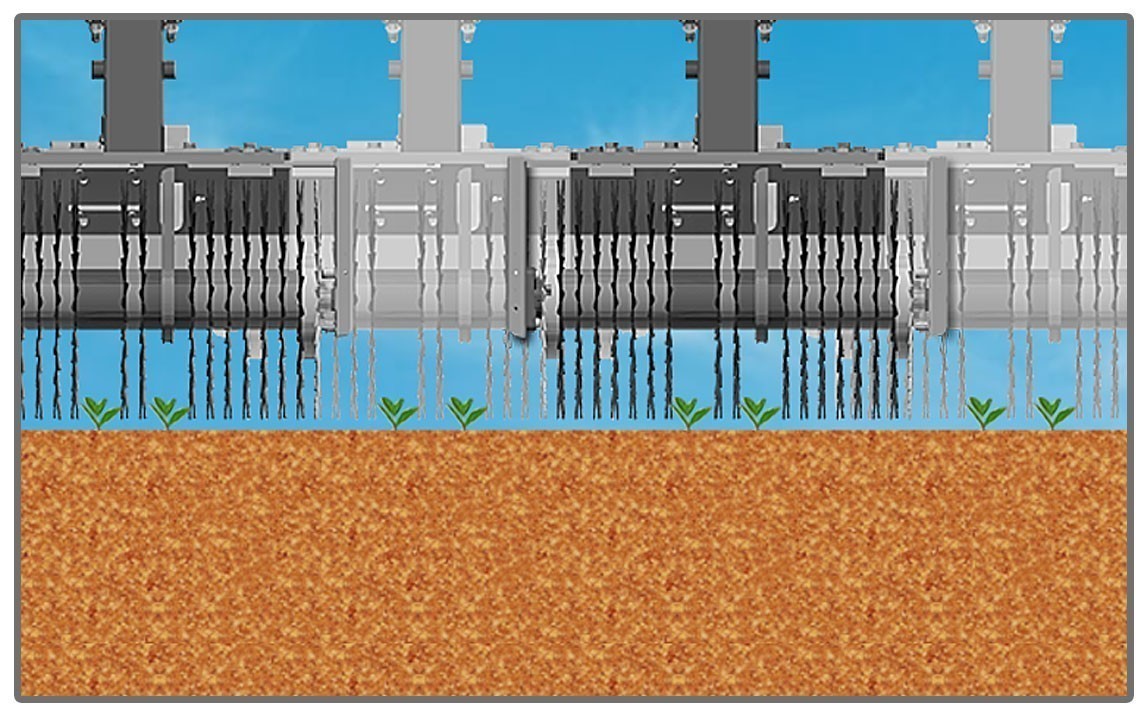

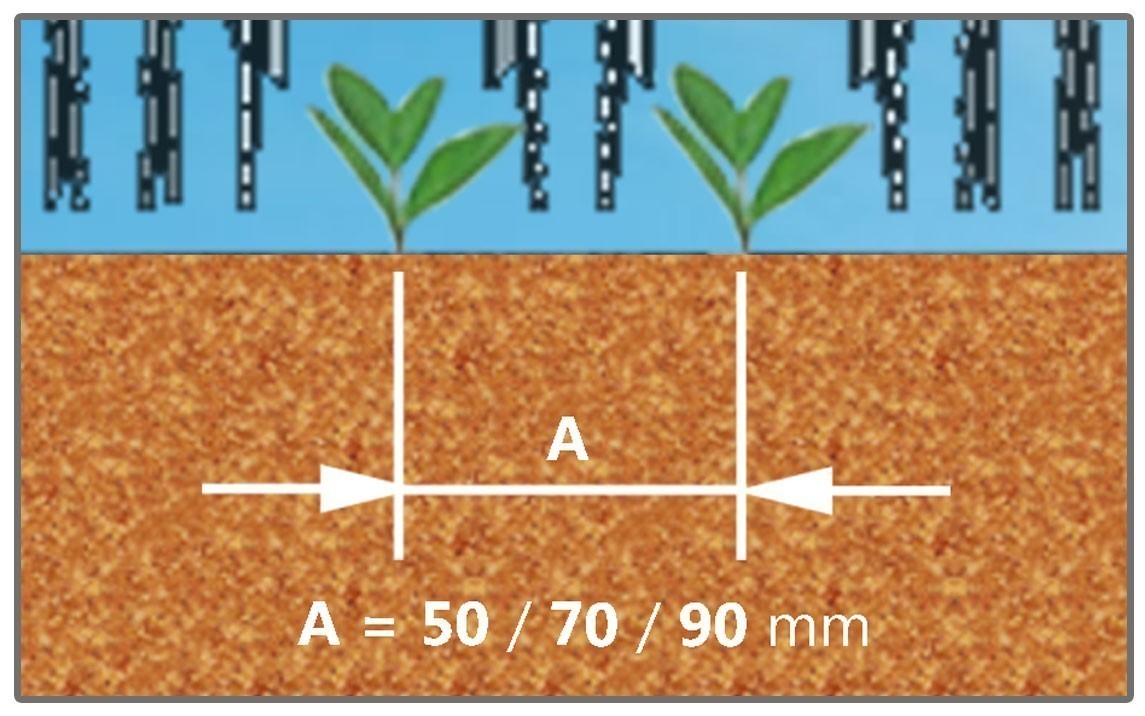

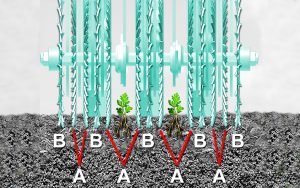

The “COLIBRI” weeding machine works directly on the sown row, 2 cm away from the plant, with a minimum interrow spacing of 4.5 cm, without damaging the root system and foliage, preventing weed germination. It is suitable for organic farming.

The “COLIBRI” weeding machine works directly on the sown row, 2 cm away from the plant, with a minimum interrow spacing of 4.5 cm, without damaging the root system and foliage, preventing weed germination. It is suitable for organic farming.

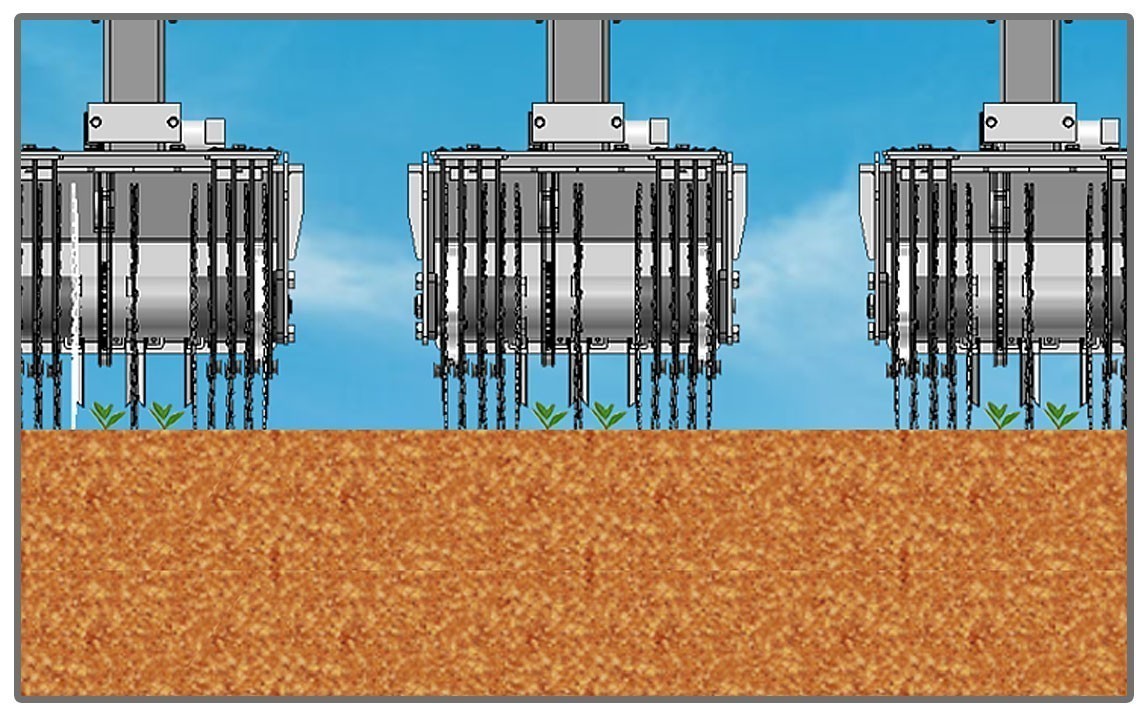

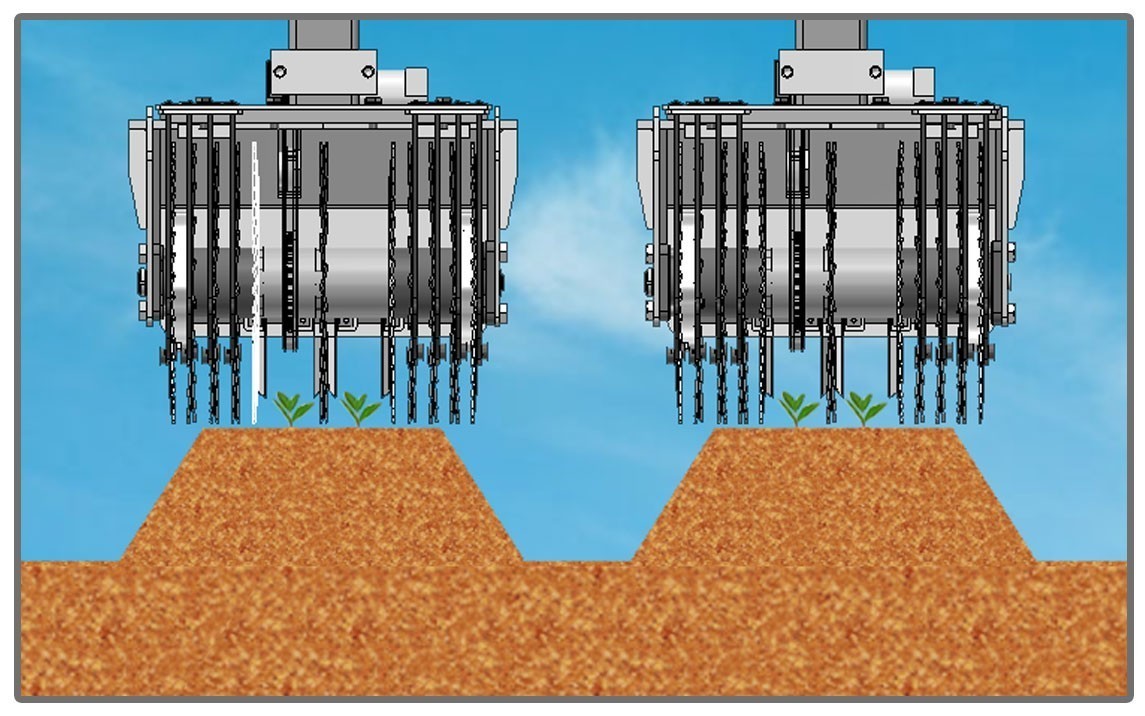

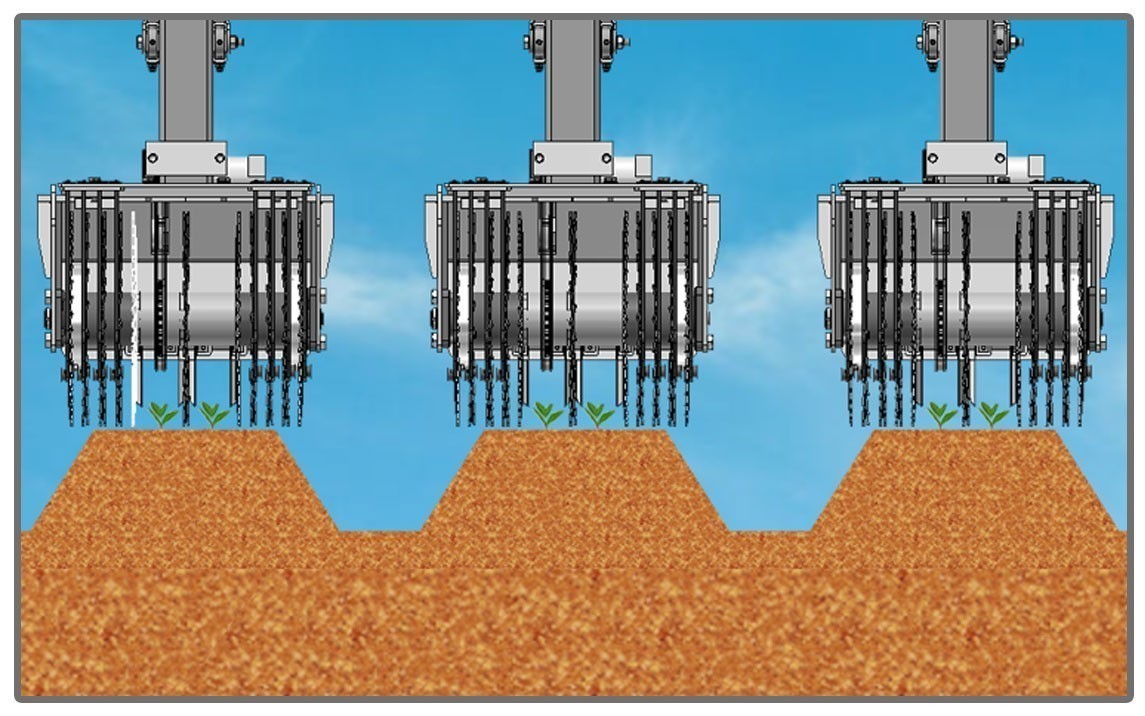

Due to its active weeding action, achieved through the motorized rotation of the discs, the COLIBRI machine gently crumbles the soil without displacing the plants. The speed and configuration of the discs can be adjusted and customized according to the plant’s growth stage and the type of soil.

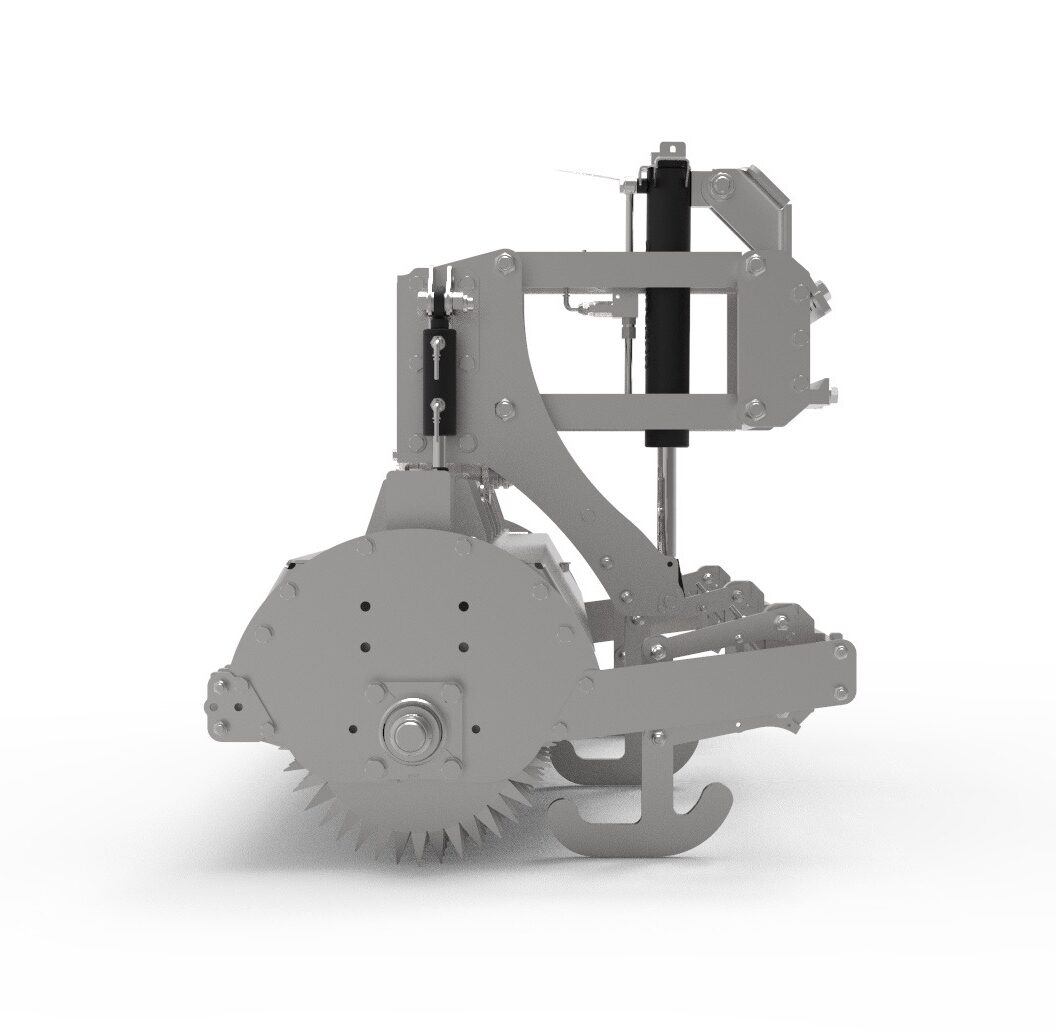

The motorized COLIBRI discs perform active weeding at a depth of 2 cm. The height is adjusted using an electro-hydraulic piston controlled by a linear potentiometer to determine the actual working depth.

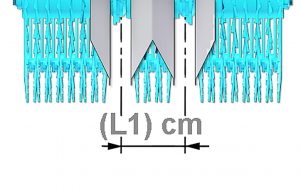

With COLIBRI, it is possible to simultaneously work on multiple rows starting from a 5 cm spacing, with disc coverage reaching 80% of the cultivated surface and 60% of the entire bed area.

The configuration of the bundles of toothed steel weeding disks, is developed based on the transplant spacing provided by the customer. Some particular features are determined by the inclination of the disc teeth:

- Teeth inclined in the opposite direction of the plant or straight: They protect the plant by compressing the soil outward. These are suitable for narrow interrow distances of 4.5 cm or when the plant is in its early growth stages and more delicate.

- Inclined sawtooth teeth, arranged in the spaces not occupied by the seedlings, dig the germination and the weeds away. They perform weed uprooting and expand the weeding range.

The discs have a diameter of 320 mm, while the teeth are 40 mm in height and work at an adjustable depth, not exceeding 30 mm, to preserve the plant’s collar. The speed and configuration of the discs can be adjusted according to the plant’s growth stage and the type of soil.

It works on all sown crops with interrow spacing (L1) ranging from 4.5 to 35 cm.

It works on all sown crops with interrow spacing (L1) ranging from 4.5 to 35 cm.

The combination of disc groups is developed based on the transplant spacing provided by the customer.

Suitable for: Carrots, baby leaf vegetables, IV Gamma crops, radishes, parsley, seeded rice, arugula, endive, basil, beets, sown on beds or flat surfaces.

The Colibrì weeding machine also offers the following advantages: it increases production and improves plant yield while reducing management costs.

- The plants grow faster, leading to earlier harvest compared to non-weeded crops.

- In the case of arugula, after the initial mowing, there is an additional benefit as it acts as an aerator, improving soil aeration.

- Moreover, using the Colibrì weeder provides the possibility to eliminate the layer of sand that is usually applied to the cultivation bed, making the overall process more efficient and cost-effective.