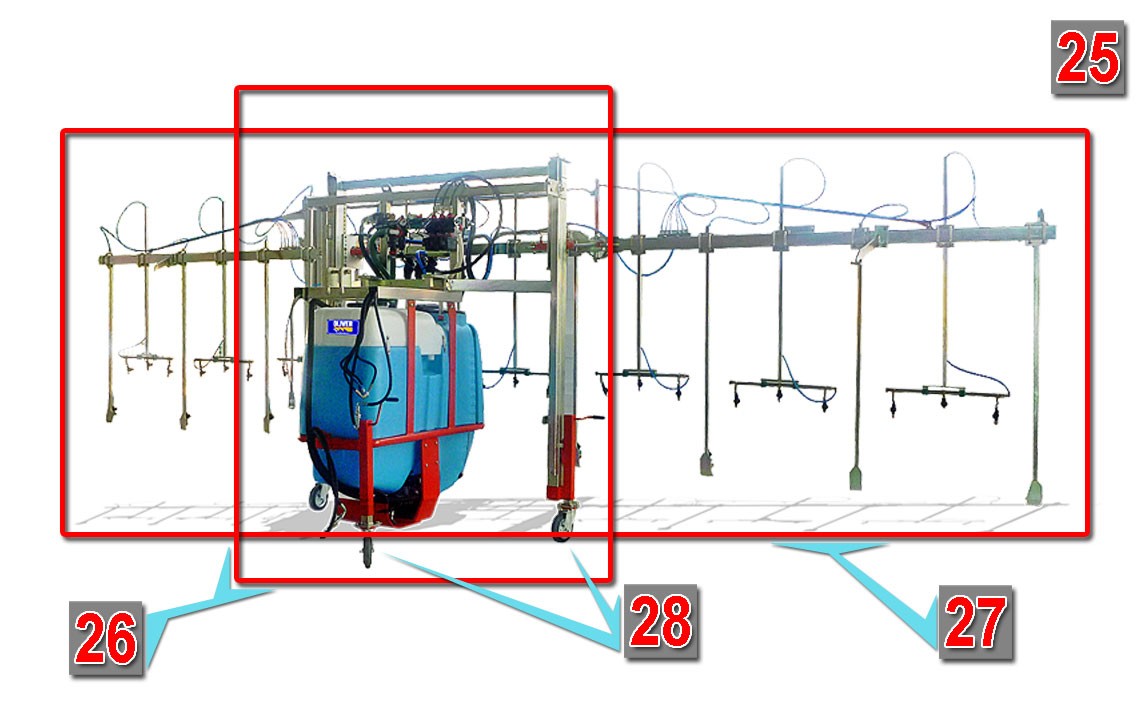

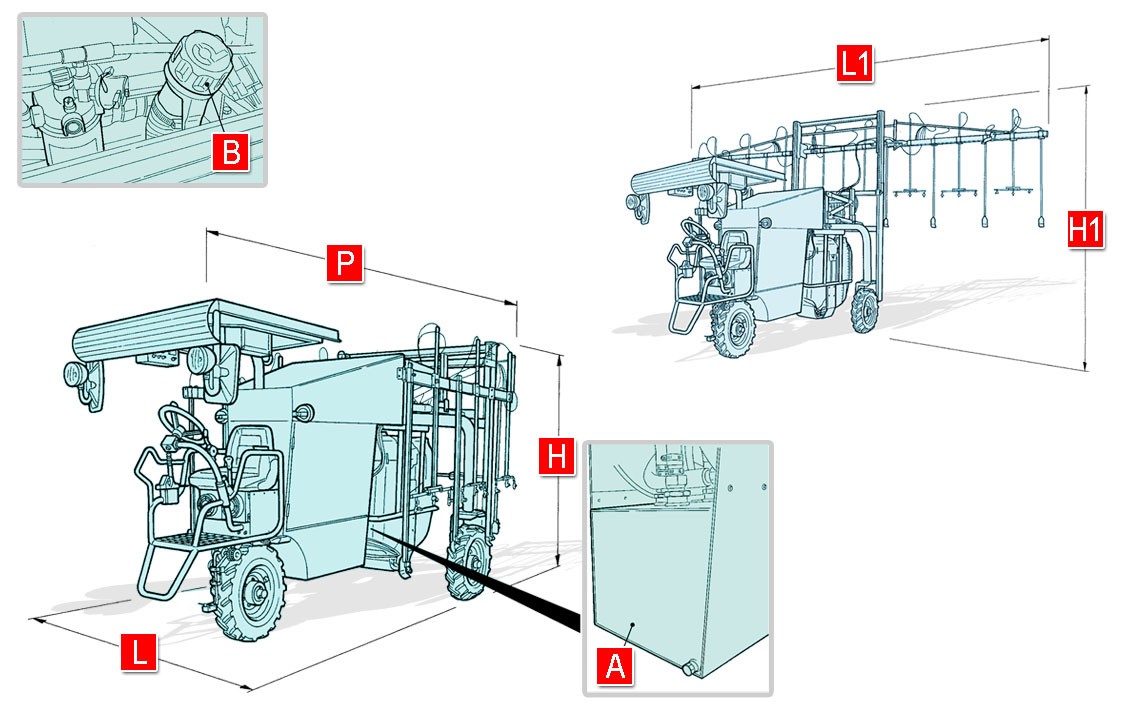

Localized Weed Equipment

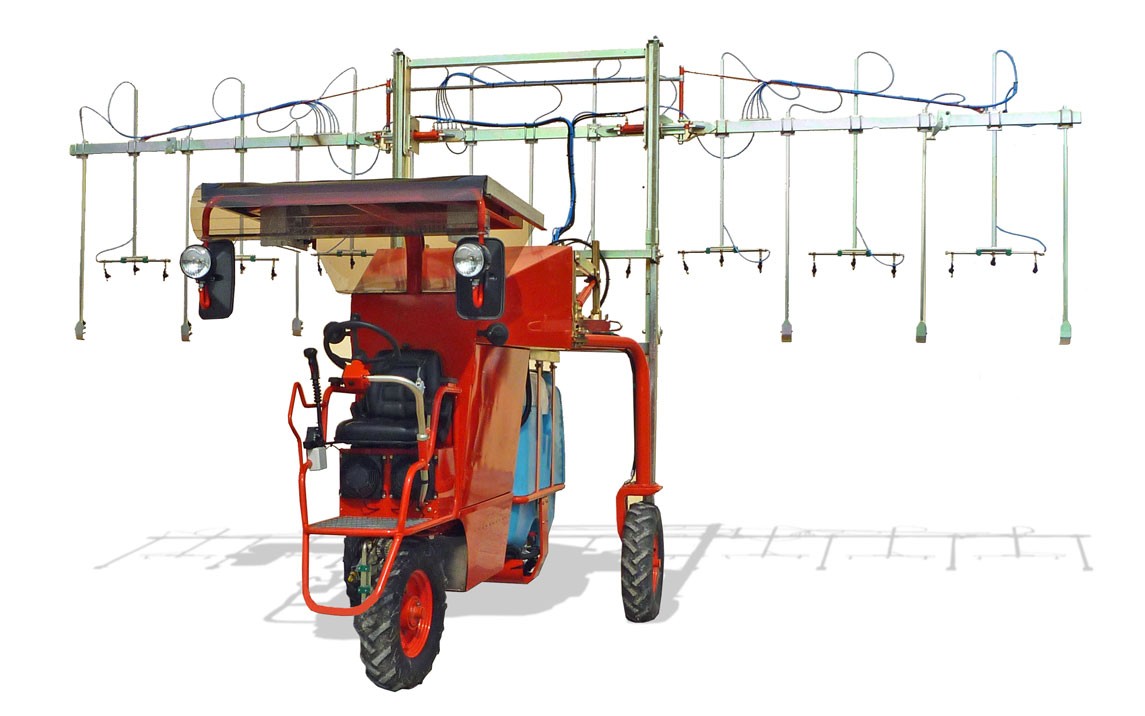

Localized weeding bar

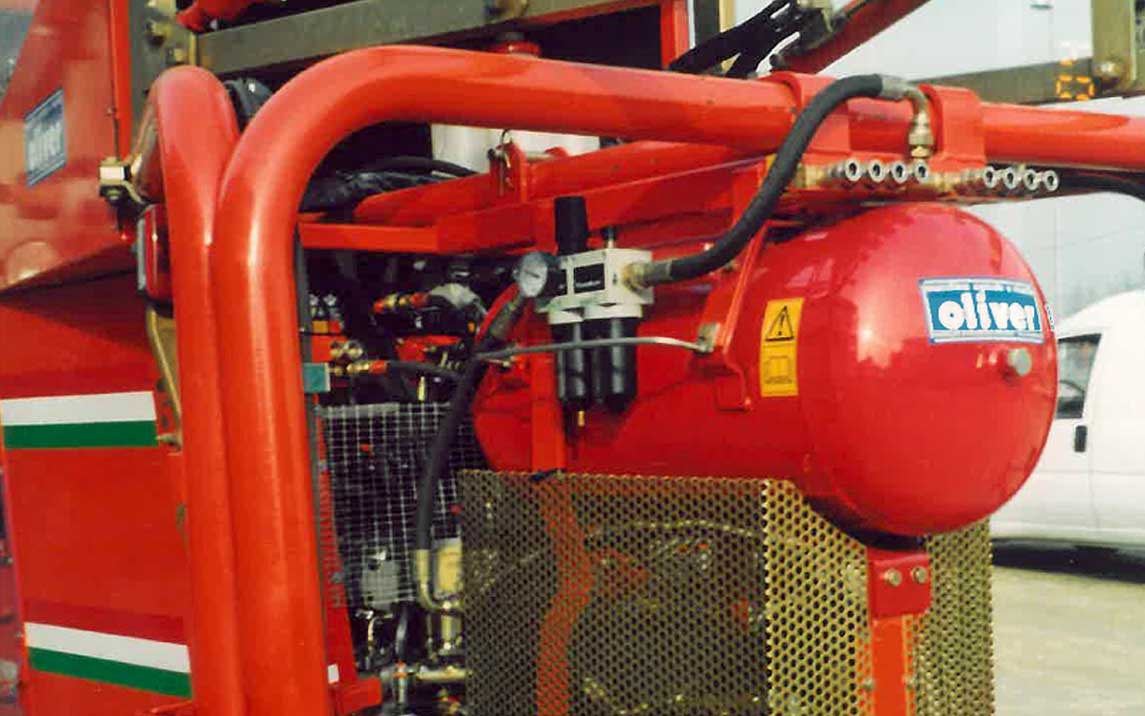

It supports the product distribution system.

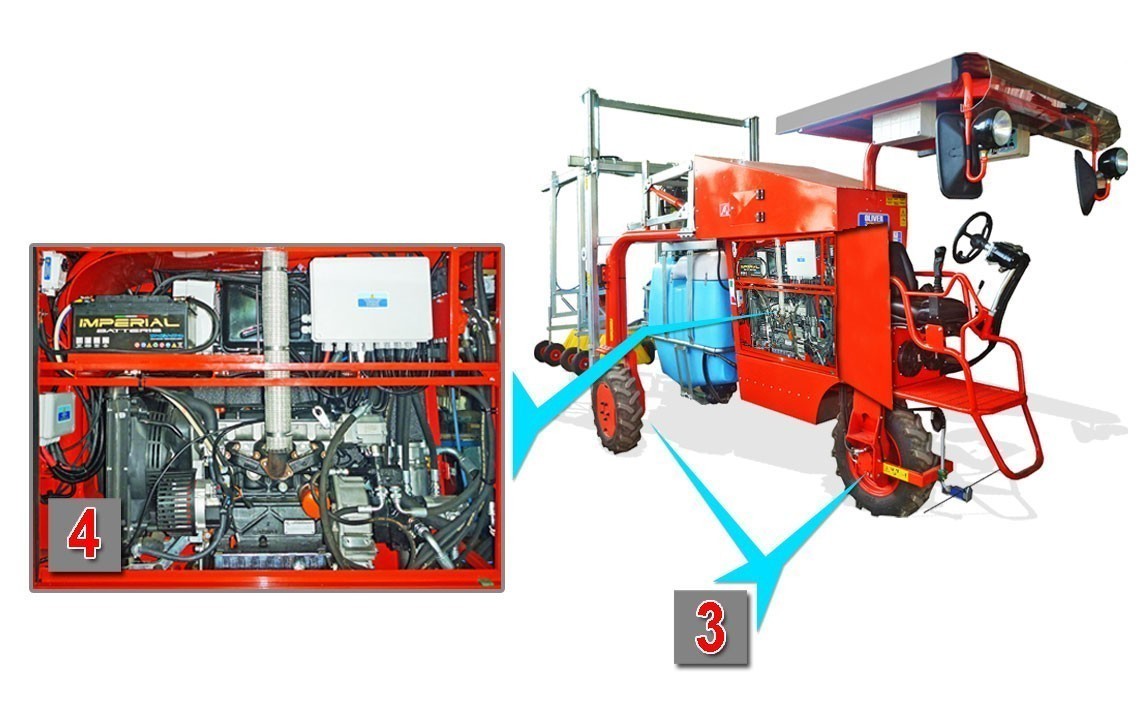

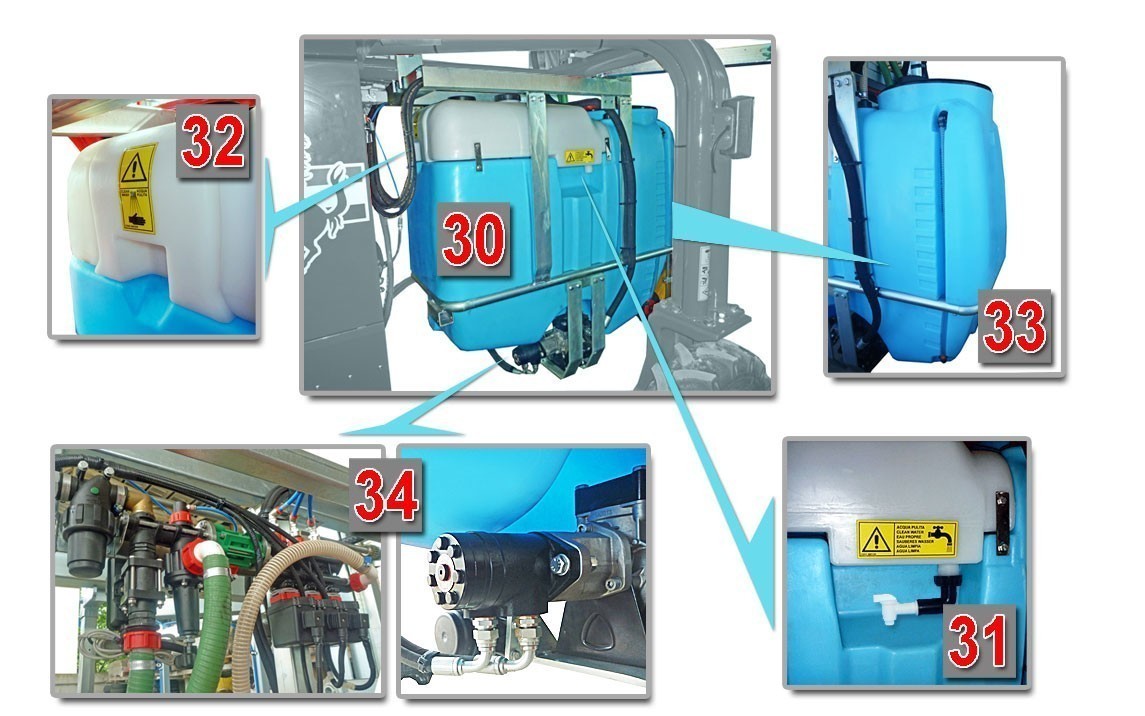

Consisting of:

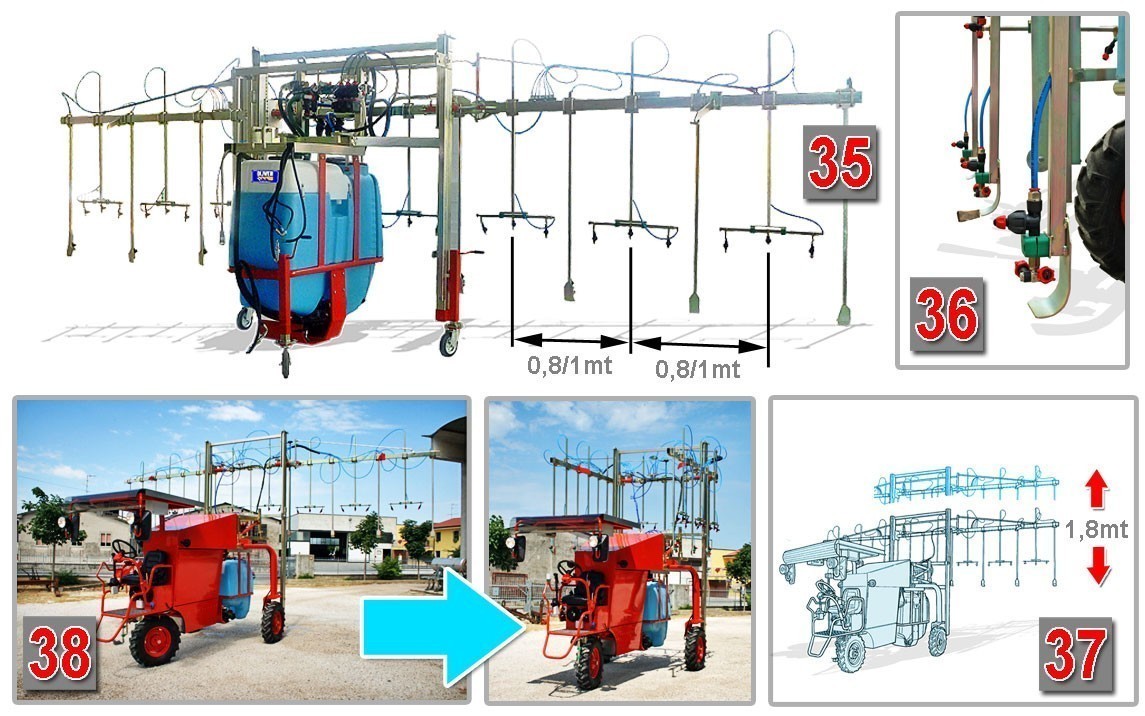

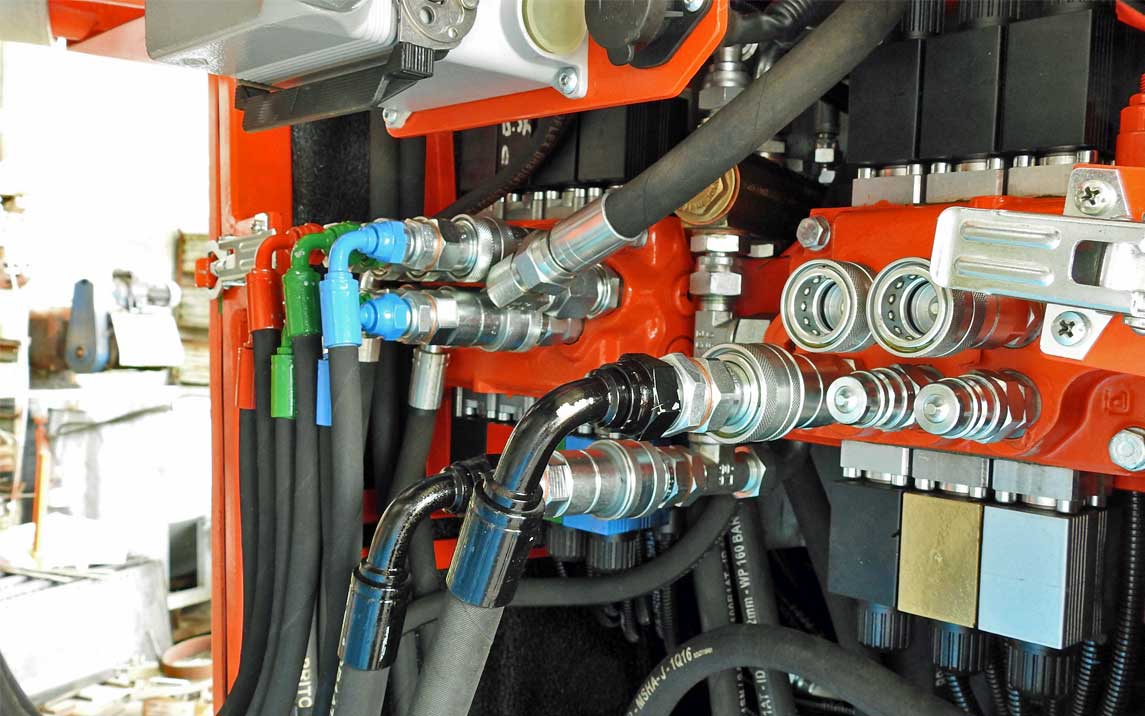

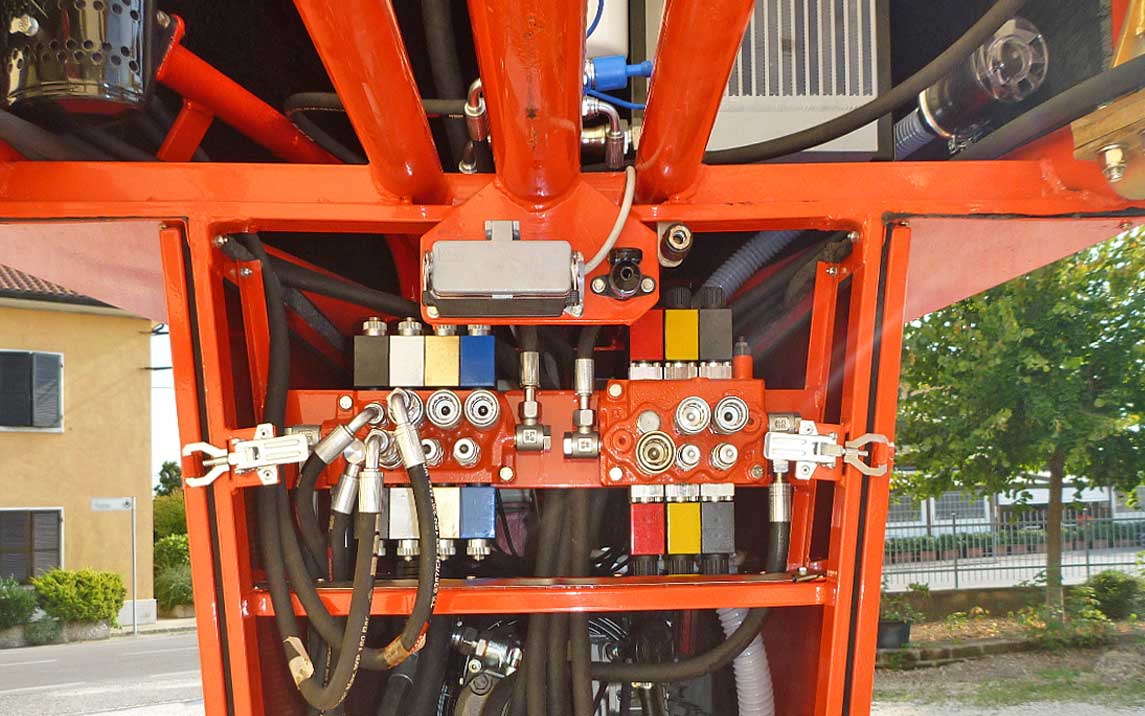

48) Galvanized metallic structure with fixed and movable tubulars, with hydraulic uprights for riser of 1,8 mt.

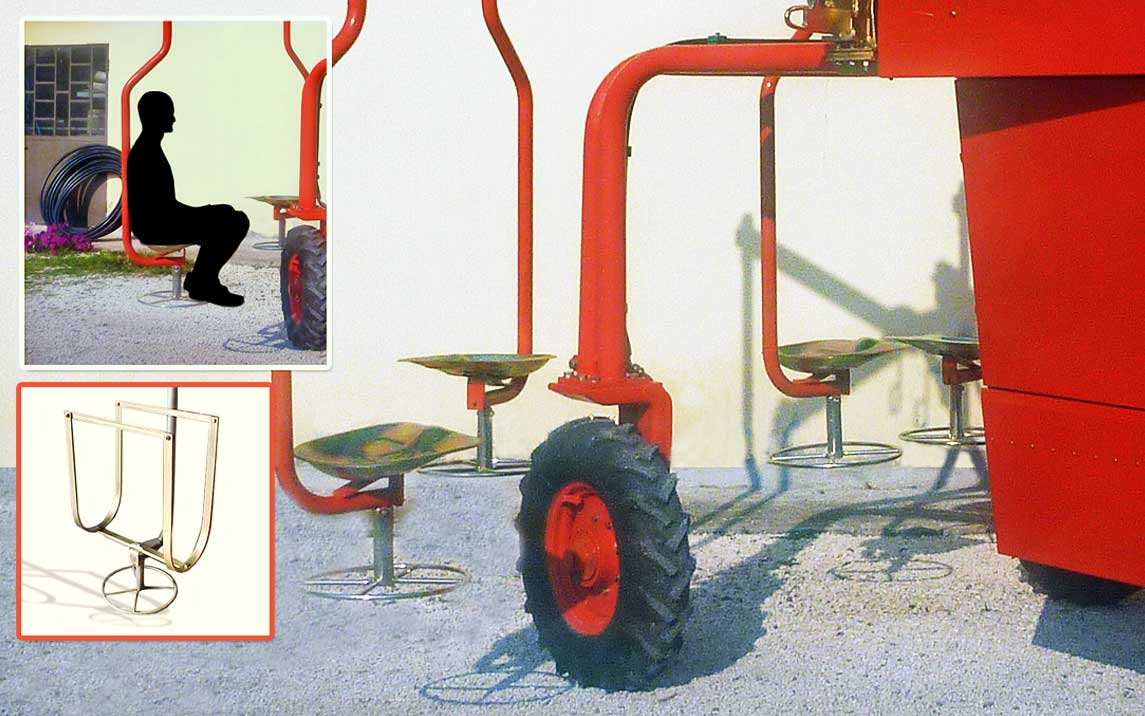

49) Element for localized weeding, formed by a parallelogram with springs,

where the locator accessory is anchored, consisting of a the customizable locating bell two jets of the TRIJET type are included, including anti-drop (50).

The jets deliver the product in a specific area, thanks to a brush

perimeter of nylon bristles, which takes the form of the the locating bell.

When not used, 2 articulated support wheels allow the parking of the single element.

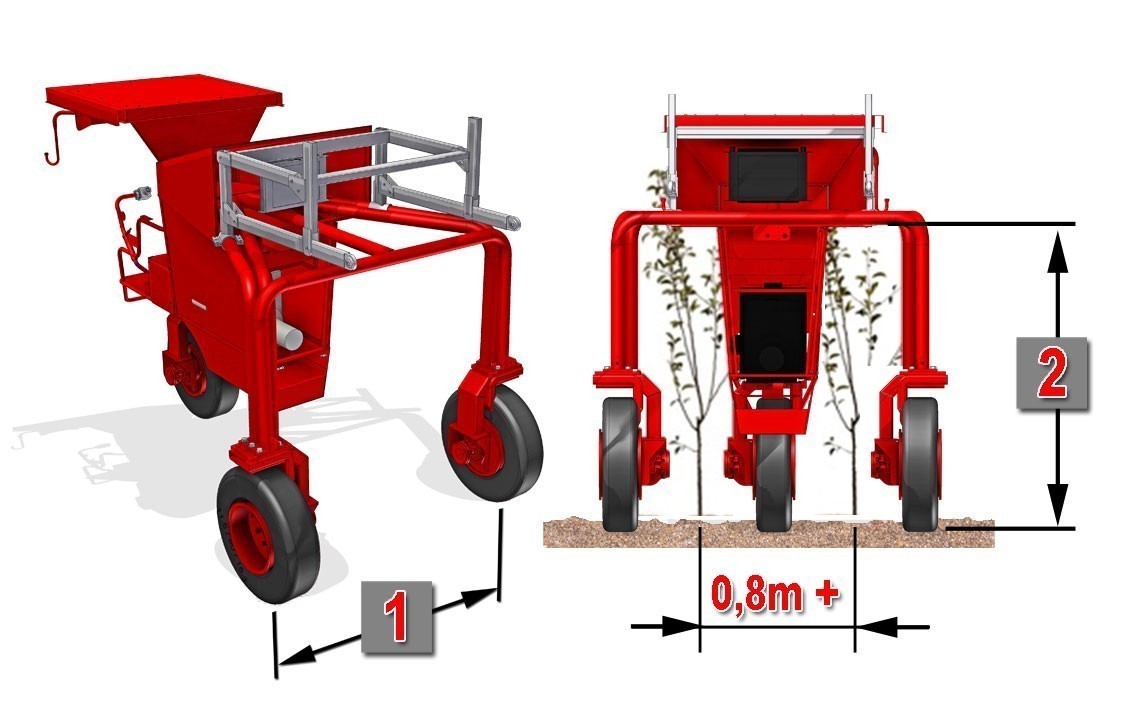

N.B. The element for localized weeding is constructed in useful working dimensions (51)We can hydraulically:

52) Varying the working height (1.8 m)

53) Fold the outer arms for the bulk during transport.

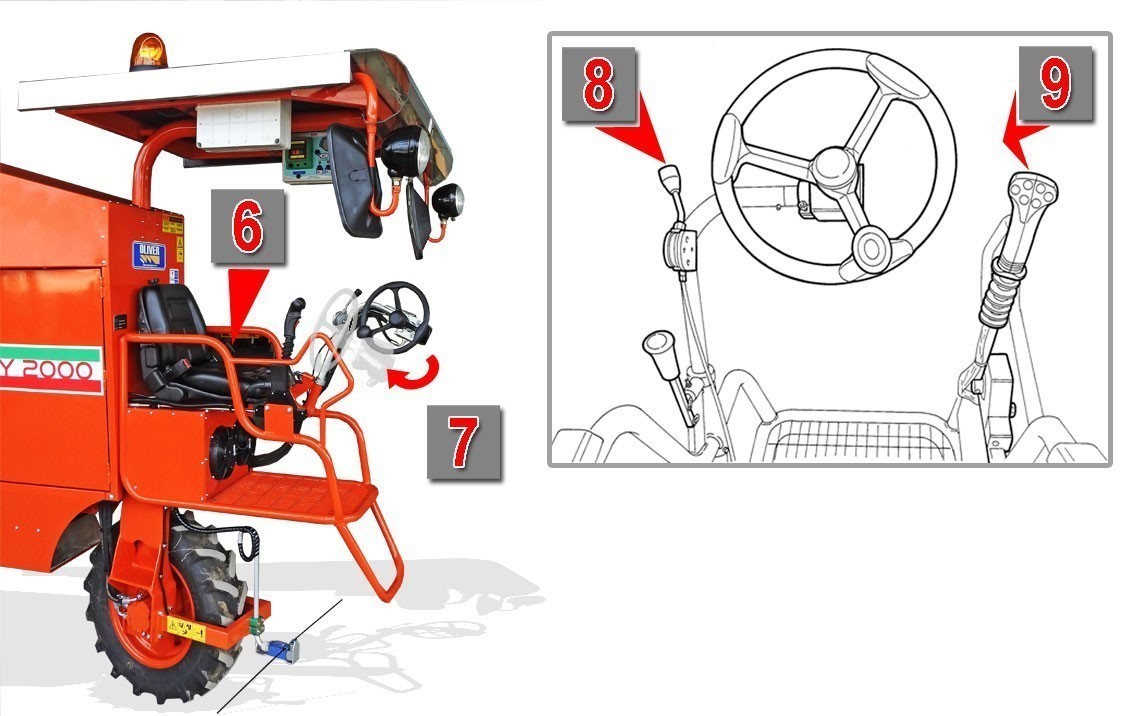

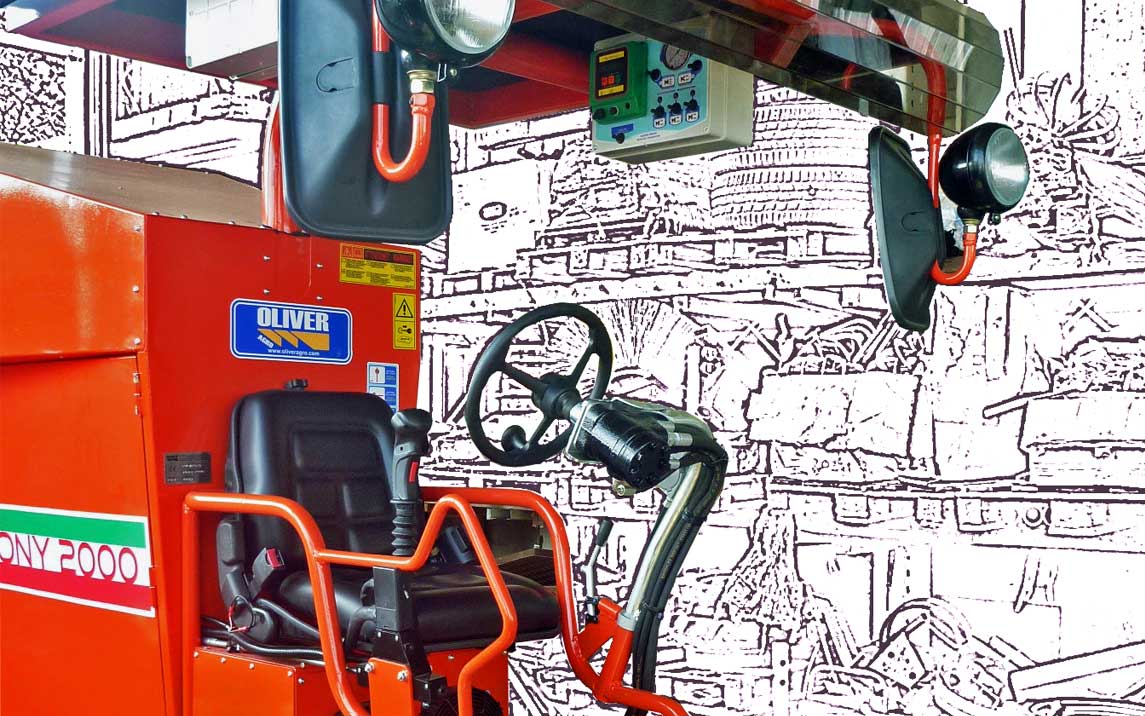

N.B. all operations are managed from the command post.