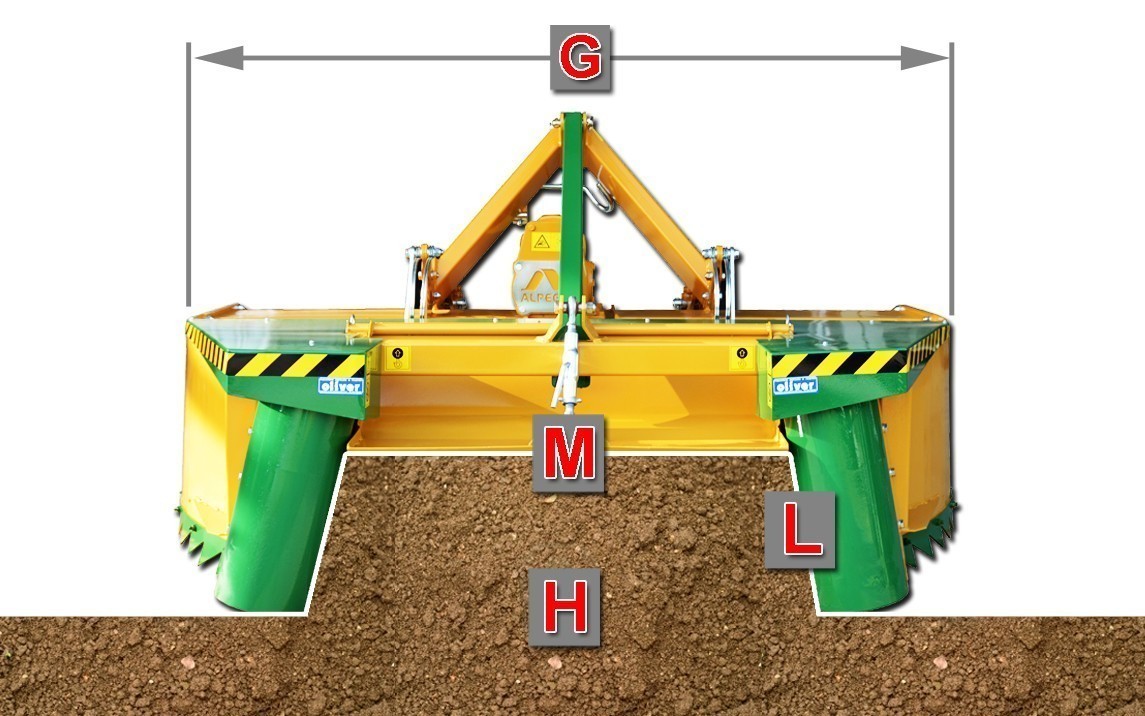

The Bed Former Machine is designed for the bed forming on worked soils or not, which are mainly compacted.

Bed Former

The result is a smooth bed, in order to lay the drip irrigation hose, to avoid unpleasant interruptions of water supply, due to the non-smooth bed.

It also serves to make the nylon adhere and roll better.